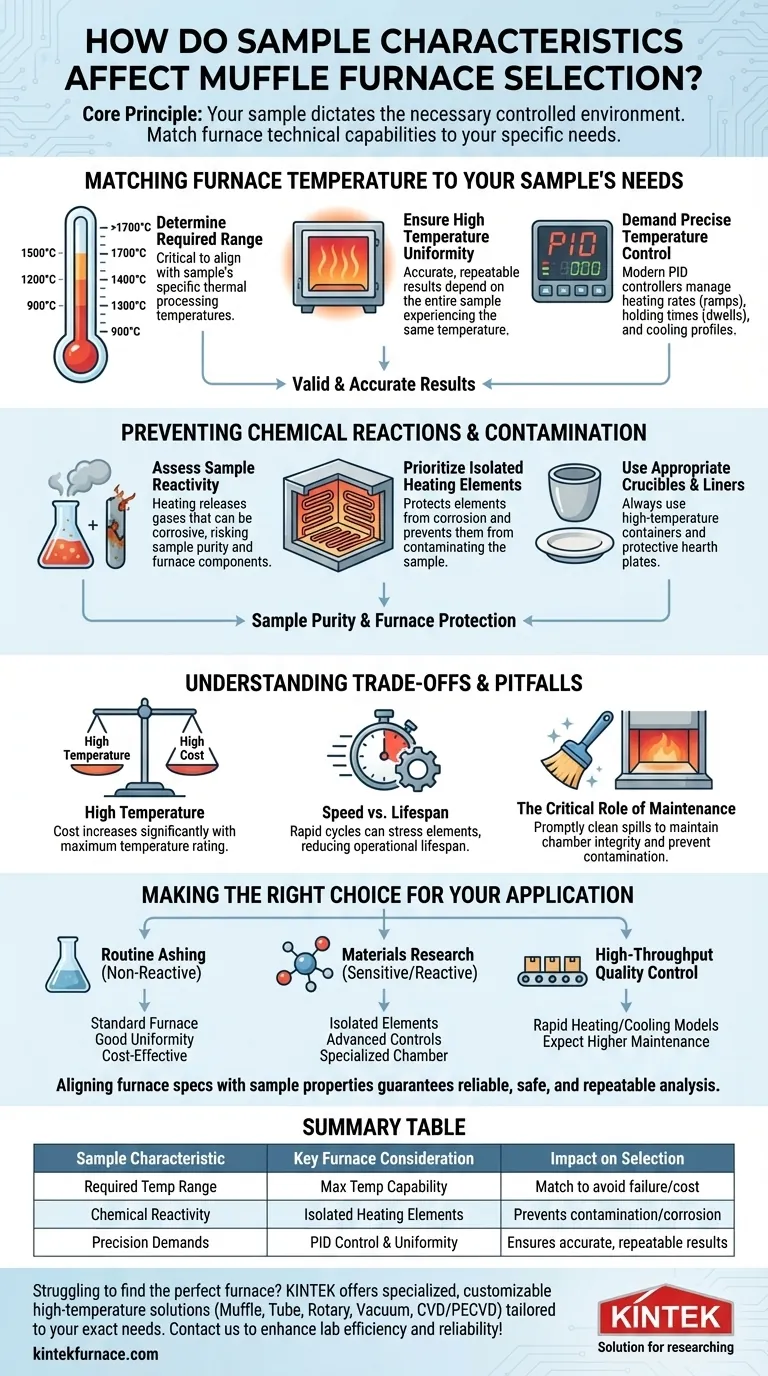

To select the right muffle furnace, you must primarily consider your sample's required temperature range, its chemical reactivity, and the precision your process demands. A furnace is not a one-size-fits-all device; its heating capabilities, chamber construction, and control systems must align directly with the specific physical and chemical properties of the material you are testing to ensure accurate results and safe operation.

The core principle is simple: A muffle furnace is a controlled environment, not just a hot box. Your sample dictates the necessary environment, and your choice of furnace is about matching its technical capabilities to that specific need.

Matching Furnace Temperature to Your Sample's Needs

The most fundamental characteristic of a muffle furnace is its ability to generate and maintain heat. This capability must be precisely aligned with your sample's requirements for the experiment to be valid.

Determine Your Required Temperature Range

Different materials undergo thermal processing at very specific temperatures. For instance, analyzing certain polymer compounds may require a range of 900°C to 1400°C.

Using a furnace that cannot reach your target temperature will render the test useless. Conversely, purchasing a furnace with a maximum temperature far exceeding your needs (e.g., 1700°C) often results in unnecessary expense.

Ensure High Temperature Uniformity

For results to be accurate and repeatable, the entire sample must experience the same temperature. High-quality furnaces provide excellent temperature uniformity across the entire chamber.

Poor uniformity means one part of your sample could be at the correct temperature while another part is not, leading to incomplete reactions, inconsistent material properties, and unreliable data.

Demand Precise Temperature Control

Modern furnaces use sophisticated digital controllers, often PID (Proportional-Integral-Derivative) controllers, to manage temperature. This is about more than just hitting a setpoint.

These controls allow you to program precise heating rates (ramps), holding times (dwells), and cooling profiles. For many advanced materials and sensitive chemical processes, how you get to the temperature is just as important as the temperature itself.

Preventing Chemical Reactions and Contamination

A muffle furnace must isolate the sample from contamination while protecting itself from potentially corrosive byproducts of the heating process.

Assess Your Sample's Reactivity

When heated, many samples release gases or fumes. These byproducts can be inert, but they can also be corrosive or reactive, posing a risk to both the sample's purity and the furnace's internal components.

Prioritize Isolated Heating Elements

In many furnace designs, the heating elements are exposed within the chamber. However, for applications involving reactive samples, it is critical to choose a furnace with isolated heating elements.

This design embeds the heating coils within the insulated chamber walls, preventing any chemical interaction between the sample's off-gassing and the elements. This protects the elements from corrosion and, more importantly, prevents the elements from contaminating your sample.

Use Appropriate Crucibles and Liners

The sample should never be placed directly on the furnace floor. Always use a high-temperature-resistant container, such as a porcelain or ceramic crucible.

For extremely corrosive samples or to protect the furnace hearth, placing an asbestos board or a ceramic plate at the bottom of the furnace chamber is a mandatory operational step.

Understanding the Trade-offs and Pitfalls

Selecting the ideal furnace involves balancing performance, longevity, and cost. Understanding the inherent trade-offs is key to making an informed decision.

High Temperature vs. High Cost

The cost of a muffle furnace increases significantly with its maximum temperature rating. Furnaces capable of reaching 1600°C or 1700°C use more advanced heating elements and insulation, making them far more expensive than standard 1100°C or 1200°C models.

Speed vs. Component Lifespan

Some models are designed for rapid heating and cooling cycles to increase throughput. While efficient, these fast thermal cycles place significant stress on the heating elements and insulation, potentially reducing their operational lifespan compared to furnaces with slower, more controlled ramps.

The Critical Role of Maintenance

Even the most advanced furnace will fail if not maintained. Spilled materials, especially metal oxides or slag, can bond with and corrode the furnace hearth.

It is crucial to promptly clean any spills or impurities to maintain the integrity of the chamber and ensure future tests are not contaminated.

Making the Right Choice for Your Application

Your choice should be guided by a clear understanding of your primary goal. Use your sample's characteristics to define your technical requirements.

- If your primary focus is routine ashing of non-reactive samples: A standard furnace with a suitable temperature range (e.g., up to 1200°C) and good temperature uniformity will be sufficient and cost-effective.

- If your primary focus is materials research with sensitive or reactive compounds: Prioritize a furnace with isolated heating elements, advanced programmable controls, and potentially a specialized, corrosion-resistant chamber.

- If your primary focus is high-throughput quality control: Consider models optimized for rapid heating and cooling, but be prepared for the associated maintenance and potential for a shorter component lifespan.

Ultimately, aligning the furnace's technical specifications with your sample's unique properties is the only way to guarantee reliable, safe, and repeatable high-temperature analysis.

Summary Table:

| Sample Characteristic | Key Furnace Consideration | Impact on Selection |

|---|---|---|

| Required Temperature Range | Maximum Temperature Capability | Must match to avoid test failure or unnecessary costs |

| Chemical Reactivity | Isolated Heating Elements | Prevents contamination and corrosion for sample purity |

| Precision Demands | PID Control and Uniformity | Ensures accurate, repeatable results with programmable profiles |

Struggling to find the perfect muffle furnace for your unique samples? At KINTEK, we specialize in high-temperature furnace solutions tailored to your exact needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether for routine ashing, sensitive materials research, or high-throughput quality control. Contact us today to discuss how we can enhance your lab's efficiency and reliability with advanced, customized furnace solutions!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing