In essence, a box type resistance furnace is a high-temperature heating chamber used for precise thermal processing of materials. It operates by passing an electric current through heating elements, generating heat via resistance. These furnaces are foundational tools in research labs and industrial settings for applications like sintering ceramics, heat-treating metals, and conducting high-temperature material analysis.

The core value of a box type resistance furnace lies in its simple, robust design which provides highly uniform and accurately controlled heat. This makes it a versatile and reliable workhorse for a wide range of material science and engineering tasks.

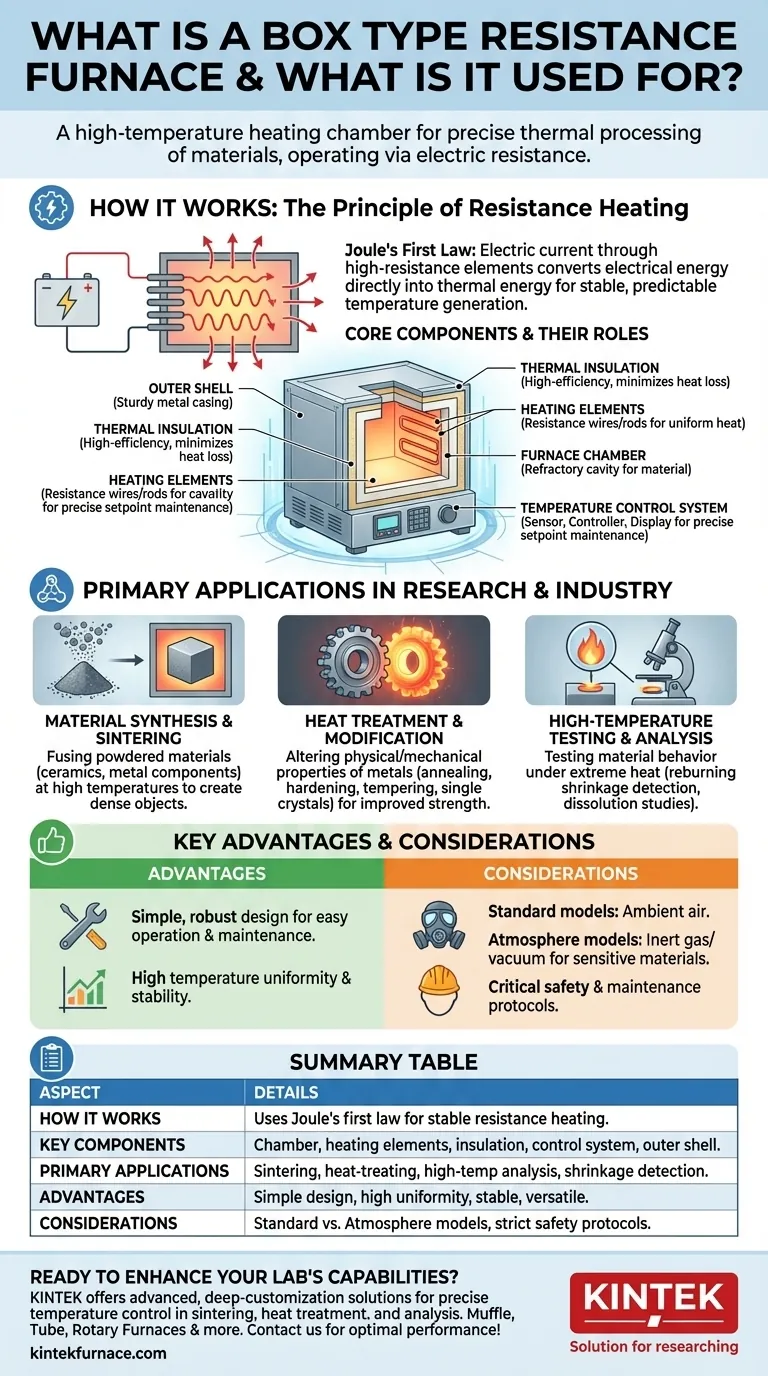

How a Box Resistance Furnace Works

To understand its utility, you must first understand its fundamental design. The furnace's operation is based on a few key principles and components working in concert.

The Principle of Resistance Heating

The furnace generates heat using Joule's first law. An electric current is passed through specialized heating elements, which have high electrical resistance. This resistance converts the electrical energy directly into thermal energy, which then radiates throughout the furnace chamber to heat the material inside.

This method allows for very stable and predictable temperature generation, as the heat output is directly related to the current applied.

Core Components and Their Roles

A box type furnace consists of several critical parts:

- Furnace Chamber: A cavity made from refractory materials that can withstand extreme temperatures. This is where the material is placed for processing.

- Heating Elements: Typically resistance wires or rods strategically placed within the chamber to ensure uniform heat distribution.

- Thermal Insulation: High-efficiency insulation, often aluminum oxide fiber, is packed between the inner chamber and the outer shell. This minimizes heat loss and improves energy efficiency.

- Temperature Control System: This is the brain of the furnace, consisting of a temperature sensor (like a thermocouple), a digital controller, and a display. It constantly measures the internal temperature and adjusts the power to the heating elements to precisely maintain the desired setpoint.

- Outer Shell: A sturdy metal casing that encloses all the components, providing structural integrity and safety.

Primary Applications in Research and Industry

The furnace's ability to create a controlled, high-temperature environment makes it indispensable for several key processes.

Material Synthesis and Sintering

This is one of the most common uses. Sintering involves heating a powdered material to a high temperature (below its melting point) to fuse the particles together, creating a solid, dense object. This is critical for manufacturing advanced ceramics and certain metal components.

Heat Treatment and Modification

Box furnaces are widely used for heat-treating metals to alter their physical and mechanical properties. Processes like annealing, hardening, and tempering are performed to increase strength, improve ductility, or relieve internal stresses within a material.

It is also used for the heat treatment of specialized materials, such as single crystals, where precise temperature control is paramount.

High-Temperature Testing and Analysis

In research and quality control, these furnaces are used to test how materials behave under extreme heat. This includes applications like reburning shrinkage detection for refractory materials or conducting dissolution and analysis studies on various metals and ceramics.

Understanding the Trade-offs and Operational Realities

While versatile, it's important to recognize the advantages and operational requirements of this equipment to use it effectively and safely.

Key Advantages: Simplicity and Precision

The primary benefits are rooted in its design. The structure is relatively simple, which makes it easy to operate and maintain. The advanced temperature control systems provide high temperature uniformity and stability, ensuring that processes are repeatable and accurate.

Specialized vs. General-Purpose Models

The standard box furnace heats materials in ambient air. However, for materials that are sensitive to oxygen or require a specific gaseous environment, a specialized atmosphere box furnace is necessary. These models have superior sealing and gas inlets, allowing them to operate with inert gases or under a vacuum.

Critical Safety and Maintenance Protocols

Operating at high temperatures poses inherent risks. It is absolutely critical that users follow all manufacturer instructions for operation. Regular inspection and maintenance are mandatory to ensure the integrity of the heating elements, insulation, and safety features. Always be familiar with the furnace's safety regulations before use.

Making the Right Choice for Your Goal

Selecting and using a box type furnace depends entirely on your specific objective.

- If your primary focus is general-purpose lab heating: The standard box type resistance furnace is a reliable and cost-effective workhorse for a wide variety of basic heat treatment and sintering tasks.

- If your primary focus is processing oxygen-sensitive materials: You must invest in a specialized atmosphere box furnace that allows for a controlled inert gas or vacuum environment.

- If your primary focus is operational safety and longevity: Prioritize strict adherence to the manufacturer's maintenance schedule and all high-temperature safety protocols.

Ultimately, this furnace is a powerful tool for anyone who needs to precisely control heat in the development or analysis of materials.

Summary Table:

| Aspect | Details |

|---|---|

| How It Works | Uses Joule's first law; electric current through heating elements generates heat via resistance for stable temperature control. |

| Key Components | Furnace chamber, heating elements, thermal insulation, temperature control system, outer shell. |

| Primary Applications | Sintering ceramics, heat-treating metals, high-temperature material analysis, reburning shrinkage detection. |

| Advantages | Simple design, easy operation and maintenance, high temperature uniformity and stability, versatile for various tasks. |

| Considerations | Standard models for ambient air; atmosphere models for inert gas/vacuum; requires strict safety and maintenance protocols. |

Ready to enhance your lab's capabilities with a reliable high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Whether you're in research or industry, our furnaces ensure precise temperature control and durability for sintering, heat treatment, and material analysis. Contact us today to discuss how we can support your projects and deliver optimal performance!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing