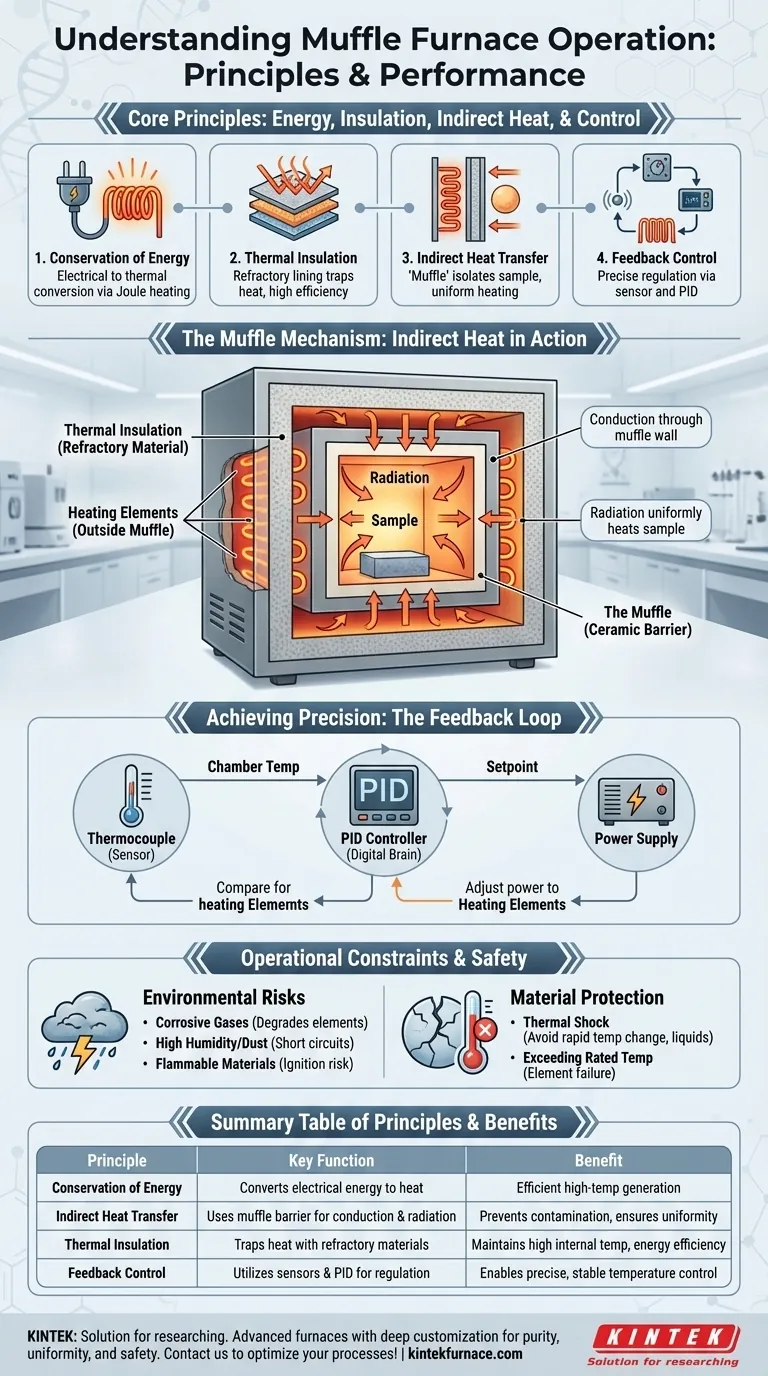

At its core, a muffle furnace operates on the integrated principles of energy conservation, indirect heat transfer, thermal insulation, and feedback control. Electrical energy is converted into heat, which is contained within an insulated chamber and precisely regulated to create a stable, high-temperature environment for processing materials without direct contact from the heating source.

A muffle furnace is an engineered system that converts electrical energy into controlled, uniform heat. Its defining feature is a physical barrier—the 'muffle'—that isolates the sample from direct heating, ensuring a clean and stable thermal environment through a precise balance of heat generation, transfer, and containment.

How Heat is Generated and Contained

The Foundation: Conservation of Energy

A muffle furnace operates on the first law of thermodynamics, or the law of conservation of energy. Electrical energy supplied to the furnace is not created or destroyed but is converted into thermal energy.

This conversion happens within the heating elements, which are typically coils of a high-resistance material. As current flows through them, their electrical resistance causes them to heat up rapidly—a phenomenon known as Joule heating.

The Role of Thermal Insulation

To be effective, the generated heat must be trapped inside the furnace chamber. This is the job of insulation, which is based on the physics of thermal conductivity.

The furnace is lined with refractory materials like ceramic fiber or firebrick. These materials have very low thermal conductivity, meaning they are poor at transferring heat. This ensures that most of the thermal energy remains inside the furnace, creating high internal temperatures while keeping the exterior shell cool and maximizing energy efficiency.

The Defining Principle: Indirect Heat Transfer

What is the "Muffle"?

The key component that gives the furnace its name is the muffle. This is a separate inner chamber, typically made of high-temperature ceramic, that contains the sample being heated.

Crucially, the heating elements are located outside this muffle. This physical separation prevents contamination of the sample from any particles shed by the heating elements and protects the elements from any off-gassing from the sample.

Heat Transfer Mechanisms

Because the heating elements do not directly touch the sample, heat must be transferred indirectly. This occurs through two primary mechanisms:

- Conduction: Heat from the elements conducts through the solid walls of the muffle.

- Radiation: The inner surface of the now-hot muffle radiates thermal energy uniformly throughout the chamber, heating the sample from all sides.

This two-step process is fundamental to achieving the clean, uniform heating environment for which muffle furnaces are valued.

Achieving Precision: Thermal Regulation

The Feedback Control Loop

Maintaining a precise and stable temperature is not passive; it requires an active feedback control system. This system constantly measures and adjusts the energy input.

A sensor, typically a thermocouple, measures the temperature inside the chamber and sends a signal to a digital controller (often a PID controller).

The controller compares the measured temperature to the user-defined setpoint. If the temperature is too low, it increases power to the heating elements; if it's too high, it cuts the power. This continuous loop ensures the temperature remains stable within very tight tolerances.

Understanding the Operational Constraints

The physical principles governing the furnace also dictate its operational limits and safety requirements. Ignoring these constraints can lead to inaccurate results, equipment damage, or hazardous situations.

Why the Environment Matters

The furnace's environment is critical. Corrosive gases can aggressively degrade the heating elements and thermocouple, while conductive dust or high humidity (>85%) can create electrical short circuits.

Flammable gases or materials are strictly prohibited, as the high internal and external surface temperatures present a significant ignition risk.

Protecting the Furnace Materials

The muffle's ceramic material is strong at high temperatures but vulnerable to thermal shock—rapid temperature change that causes cracking. Never place cold or liquid samples into a hot furnace or pour any liquids inside, as this can destroy the muffle.

Likewise, every heating element has a maximum rated temperature. Exceeding this limit will cause the elements to degrade quickly or fail completely. Safety features like over-temperature protection exist to prevent this.

Applying These Principles for Optimal Results

- If your primary focus is process purity and avoiding contamination: The principle of indirect heating is your greatest asset, as the muffle physically isolates your sample from the heating elements.

- If your primary focus is temperature uniformity and stability: Rely on the combination of robust insulation to minimize heat loss and a well-calibrated feedback control system to maintain your setpoint.

- If your primary focus is furnace longevity and safety: Respect the physical limits of the materials by staying within the rated temperature and avoiding thermal shock from liquids or rapid cooling.

Understanding these interconnected principles transforms the furnace from a simple box of heat into a precise and reliable scientific instrument.

Summary Table:

| Principle | Key Function | Benefit |

|---|---|---|

| Conservation of Energy | Converts electrical energy to heat via Joule heating | Efficient energy use for high temperatures |

| Indirect Heat Transfer | Uses a muffle barrier for conduction and radiation | Prevents sample contamination and ensures uniform heating |

| Thermal Insulation | Employs refractory materials to trap heat | Maintains high internal temperatures and energy efficiency |

| Feedback Control | Utilizes thermocouples and PID controllers for regulation | Enables precise, stable temperature control |

Ready to elevate your laboratory's capabilities with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for purity, uniformity, and safety. Contact us today to discuss how our expertise can optimize your processes and deliver reliable results!

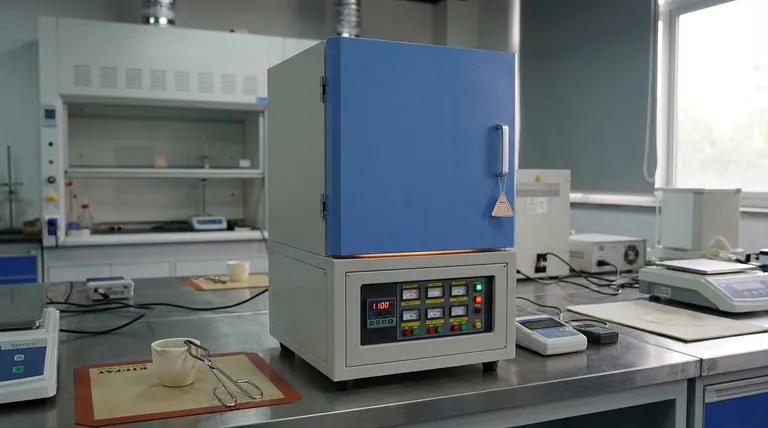

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation