In semiconductor manufacturing, box type resistance furnaces serve two primary functions: they create the critical silicon dioxide (SiO₂) insulating layers on wafers through thermal oxidation, and they repair and stabilize the microscopic metal wiring through a process called metallization annealing. These furnaces provide the precise, high-temperature, and atmosphere-controlled environment necessary for these foundational fabrication steps.

The box resistance furnace is not a specialized semiconductor tool, but rather a universal high-temperature oven. Its value in chip manufacturing comes from leveraging its core strengths—excellent temperature uniformity and atmosphere control—to perform specific, high-impact thermal processes on batches of silicon wafers.

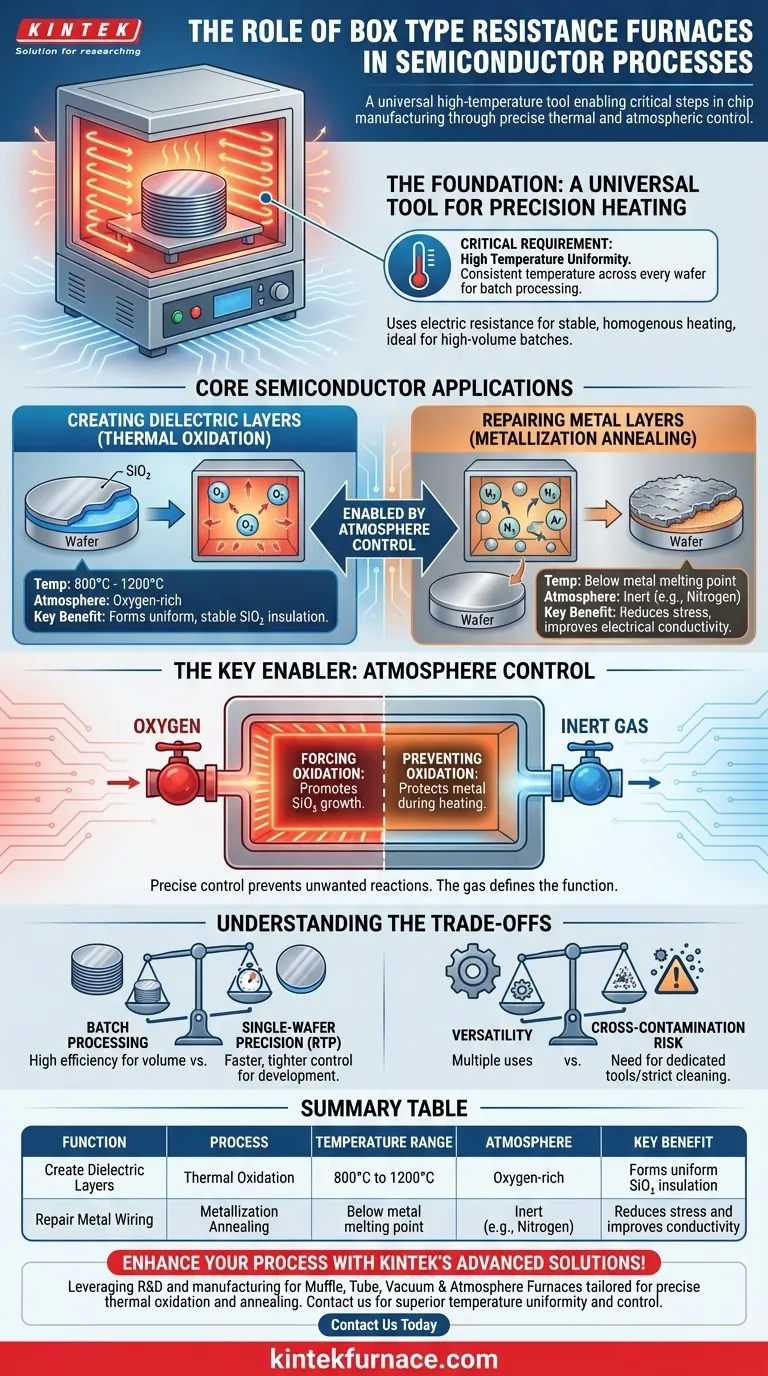

The Foundation: A Universal Tool for Precision Heating

What is a Box Resistance Furnace?

A box type resistance furnace is a foundational piece of thermal processing equipment. It uses electrical resistance in heating elements, typically wires or rods, to generate high temperatures inside an insulated chamber.

Heat is transferred to the material inside through thermal radiation and convection. Their simple design, reliability, and operational flexibility make them a workhorse in many industries, from metallurgy to ceramics.

The Critical Requirement: Temperature Uniformity

For semiconductor manufacturing, the most important characteristic of these furnaces is their ability to maintain high temperature uniformity. Every silicon wafer, and every point on that wafer, must experience the exact same temperature.

Any variation can lead to differences in layer thickness or material properties, resulting in failed chips. Box furnaces are designed to provide a stable, homogenous thermal environment, making them ideal for batch processing where consistency across dozens of wafers is paramount.

Core Semiconductor Applications

Creating Dielectric Layers: Oxidation Diffusion

One of the most fundamental steps in chip fabrication is growing a layer of silicon dioxide (SiO₂) on the silicon wafer. This layer acts as an extremely effective electrical insulator, or dielectric, which is essential for building transistors.

To achieve this, wafers are placed in a furnace heated to between 800°C and 1200°C in an oxygen-rich atmosphere. This process, known as thermal oxidation, causes the silicon on the wafer's surface to react with the oxygen, forming a thin, uniform, and highly stable SiO₂ layer.

Repairing and Refining Metal Layers: Metallization Annealing

After microscopic metal circuits, often made of aluminum, are deposited onto the wafer, they contain structural stress and imperfections from the sputtering process. This can lead to high electrical resistance and poor connections.

To fix this, the wafers undergo metallization annealing. They are heated in the furnace to a temperature below the metal's melting point. This process helps repair the crystal structure of the metal film, relieves internal stresses, and improves the electrical contact between the metal and the silicon, reducing contact resistance.

The Key Enabler: Atmosphere Control

Why the Gas Inside Matters

Modern resistance furnaces used in semiconductor fabrication are also atmosphere furnaces. This means the operator has precise control over the gaseous environment inside the chamber.

Controlling the atmosphere is critical because it prevents unwanted chemical reactions while enabling desired ones. Simply heating a material in ambient air would cause uncontrolled oxidation and contamination.

Forcing Oxidation vs. Preventing It

The furnace's role changes depending on the gas used. This is how the same piece of equipment can perform two seemingly opposite functions.

For oxidation diffusion, pure oxygen is intentionally pumped into the chamber to promote the growth of the SiO₂ layer.

For metallization annealing, an inert gas like nitrogen or argon is used. This purges all oxygen, creating a non-reactive environment that allows the metal to be heated without oxidizing, which would ruin its conductive properties.

Understanding the Trade-offs

Batch Processing vs. Single-Wafer Precision

Box furnaces are designed for batch processing, meaning they can heat many wafers at once. This makes them highly efficient and cost-effective for established, high-volume processes like thermal oxidation.

However, for cutting-edge development that requires extremely rapid temperature changes, single-wafer systems like Rapid Thermal Processing (RTP) often provide faster cycle times and tighter control, albeit at a higher cost per wafer.

A Workhorse, Not a Specialist

Because they are versatile tools used for various thermal steps, there is an inherent risk of cross-contamination if a furnace is not dedicated to a specific, ultra-clean process.

Managing furnace cleanliness and process scheduling is a critical operational task to ensure that residue from one step does not compromise the purity required for another.

Applying This to Your Process

Choosing and utilizing a furnace requires understanding its function in your specific goal.

- If your primary focus is creating robust insulation layers: The furnace's role is to provide a stable, high-temperature, and precisely controlled oxygen environment for uniform thermal oxidation.

- If your primary focus is ensuring reliable electrical connections: The furnace's role is to heat-treat metal films in a completely inert atmosphere to repair deposition damage and lower electrical resistance.

Ultimately, the box resistance furnace is a fundamental and indispensable workhorse, enabling some of the most critical transformations a silicon wafer undergoes on its journey to becoming a finished chip.

Summary Table:

| Function | Process | Temperature Range | Atmosphere | Key Benefit |

|---|---|---|---|---|

| Create Dielectric Layers | Thermal Oxidation | 800°C to 1200°C | Oxygen-rich | Forms uniform SiO₂ insulation |

| Repair Metal Wiring | Metallization Annealing | Below metal melting point | Inert (e.g., Nitrogen) | Reduces stress and improves conductivity |

Enhance your semiconductor processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for precise thermal oxidation and annealing. Our strong deep customization capability ensures your unique experimental requirements are met with superior temperature uniformity and atmosphere control. Contact us today to discuss how our furnaces can boost your lab's efficiency and yield!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency