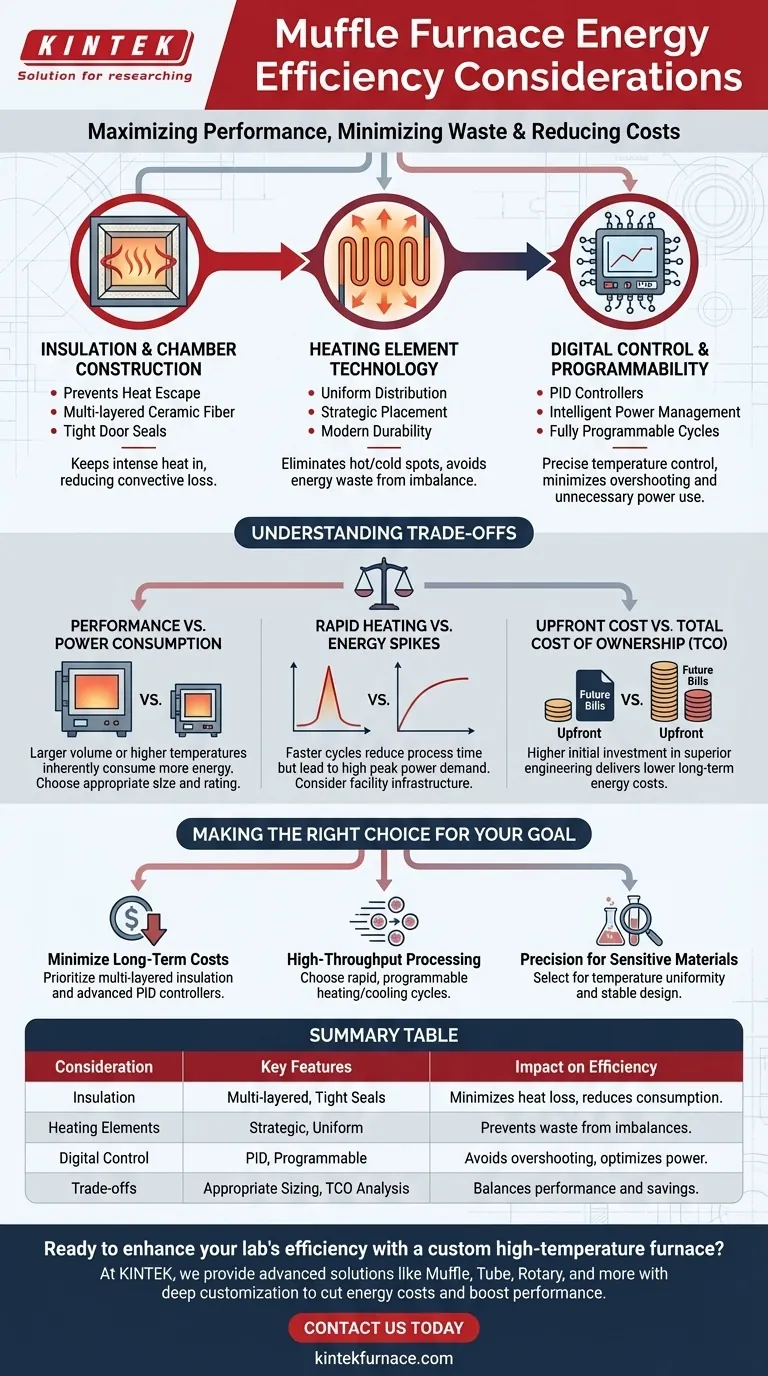

The primary considerations for muffle furnace energy efficiency are the quality of the thermal insulation, the design of the heating elements, and the precision of the temperature control system. A furnace that excels in these three areas will minimize heat loss and prevent energy waste from temperature overshoots, directly reducing operational costs and improving sustainability.

Achieving the high, uniform temperatures a muffle furnace provides is an energy-intensive process. True efficiency is not found in a single feature, but in a system where advanced insulation, modern heating elements, and intelligent controls work together to deliver precise heat with minimal waste.

The Core Pillars of Muffle Furnace Efficiency

To evaluate a furnace's efficiency, you must look beyond its maximum temperature and examine the engineering that contains and controls that heat.

Insulation and Chamber Construction

The single most significant factor in energy efficiency is the furnace's ability to prevent heat from escaping. Wasted heat is wasted energy.

High-quality thermal insulation, typically multi-layered ceramic fiber, is critical. It has low thermal conductivity, meaning it keeps the intense heat inside the chamber and away from the outer casing.

A well-constructed furnace with tight door seals is also essential. Even small gaps can lead to significant convective heat loss, forcing the system to consume more power to maintain its setpoint.

Heating Element Technology

Modern heating elements are designed for rapid heating and durability, but their placement is also key to efficiency.

Elements strategically placed around the chamber ensure uniform heat distribution. This uniformity eliminates hot and cold spots, meaning the controller doesn't need to expend extra energy trying to stabilize an uneven temperature.

Digital Control and Programmability

Precision is the enemy of waste. Modern digital furnaces use Proportional-Integral-Derivative (PID) controllers to intelligently manage power.

These controllers learn the furnace's thermal behavior, allowing them to bring the chamber to the target temperature with minimal overshooting. This prevents the wasteful cycle of over-heating and then cooling down.

Furthermore, fully programmable controls allow you to tailor heating and cooling rates to your specific process. This ensures you use only the energy required for the task, rather than running the furnace at full power unnecessarily.

Understanding the Trade-offs

An efficient furnace is not always the one that uses the least absolute power. The key is understanding the balance between performance requirements and energy consumption.

Performance vs. Power Consumption

A larger furnace or one capable of reaching higher temperatures (e.g., 1800°C vs. 1200°C) will inherently consume more energy. There is no way around the physics of heating a larger volume to a more extreme temperature.

The goal is to choose a model appropriately sized for your typical workpiece and rated for the temperatures you actually need, avoiding the inefficiency of a vastly oversized or over-specified unit.

Rapid Heating vs. Energy Spikes

Modern furnaces often feature rapid heating and cooling cycles. While this can reduce total process time and therefore overall energy consumption per run, it can lead to high peak power demand.

This is a critical consideration for your facility's electrical infrastructure. A slower, more gradual heating cycle may be more efficient from a power grid perspective, even if the total run time is longer.

Upfront Cost vs. Total Cost of Ownership

Less expensive furnaces often cut costs on insulation and control systems. While the initial purchase price is lower, their poor thermal efficiency results in significantly higher energy bills over the furnace's lifespan.

A well-engineered furnace with superior insulation and precise controls may have a higher upfront cost but will deliver a lower Total Cost of Ownership (TCO) through years of reduced energy consumption.

Making the Right Choice for Your Goal

Select a furnace by matching its efficiency features to your primary operational objective.

- If your primary focus is minimizing long-term operational costs: Prioritize models with documented high-quality, multi-layered insulation and an advanced PID controller.

- If your primary focus is high-throughput sample processing: Choose a furnace with rapid, fully programmable heating and cooling cycles to minimize the energy used per cycle.

- If your primary focus is precision for sensitive materials: Select a furnace praised for its temperature uniformity, as this indicates an efficient design that doesn't waste energy correcting for thermal imbalances.

By understanding these principles, you can select a furnace that delivers precise performance without compromising on operational efficiency.

Summary Table:

| Consideration | Key Features | Impact on Efficiency |

|---|---|---|

| Insulation | Multi-layered ceramic fiber, tight seals | Minimizes heat loss, reduces energy consumption |

| Heating Elements | Strategic placement, uniform distribution | Prevents energy waste from temperature imbalances |

| Digital Control | PID controllers, programmable settings | Avoids overshooting, optimizes power use |

| Trade-offs | Appropriate sizing, TCO analysis | Balances performance with energy savings |

Ready to enhance your lab's efficiency with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, helping you cut energy costs and boost performance. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres