At their core, muffle furnaces are uniquely suited for sensitive materials because they provide a triple guarantee of precision, purity, and protection. The defining feature is an internal chamber, or "muffle," that physically isolates the material from the heating elements. This separation prevents direct contamination while enabling exceptionally uniform and precisely controlled temperatures, safeguarding materials that would otherwise be damaged or compromised.

The true value of a muffle furnace is not just its ability to generate high heat, but its ability to deliver that heat in an absolutely clean, stable, and homogenous environment. This makes it an indispensable tool for processes where material integrity is paramount.

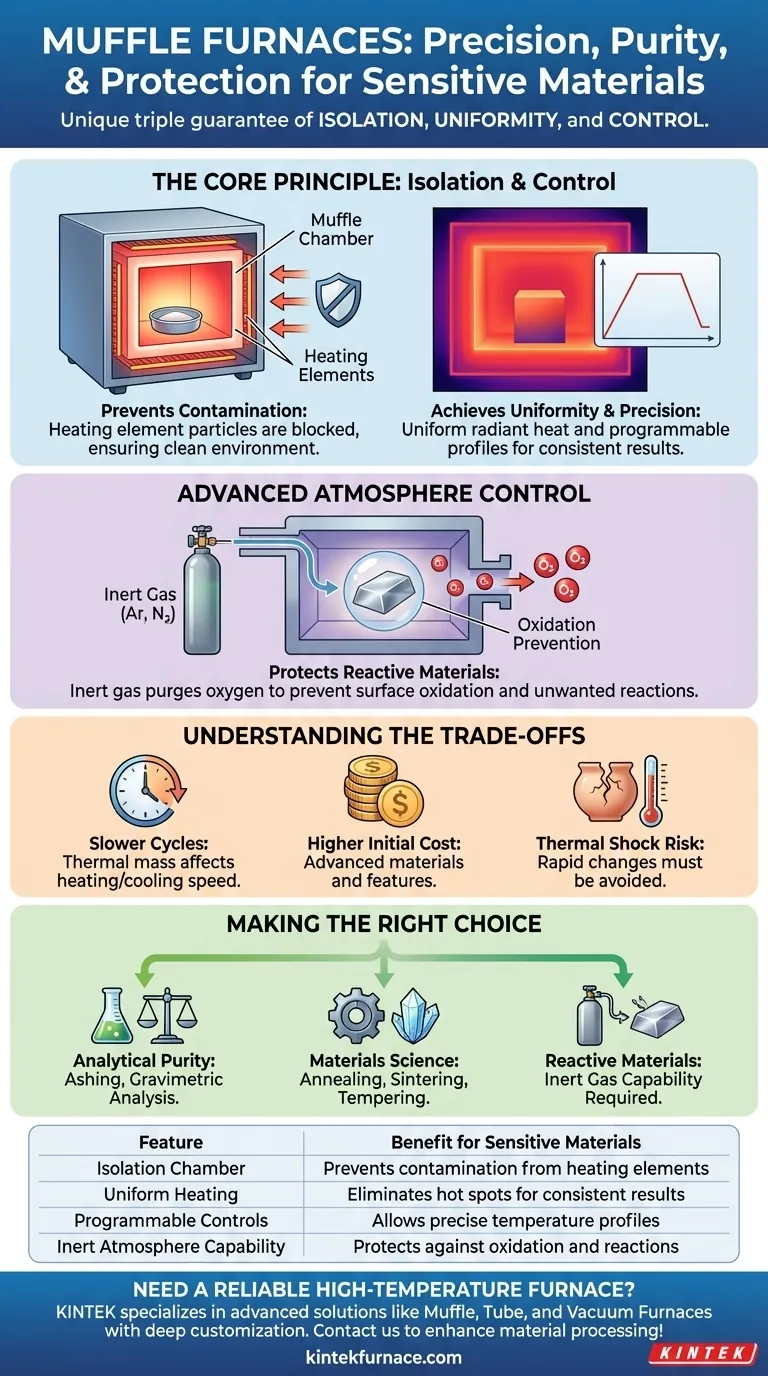

The Core Principle: Isolation and Control

A muffle furnace's design is fundamentally different from a simple high-temperature oven. The key is the indirect heating method, where the "muffle" chamber acts as a perfect intermediary.

Preventing Contamination

The heating elements in a furnace can degrade over time and release microscopic particles. In a direct-heating oven, these contaminants can deposit onto your sample.

The muffle acts as a physical barrier. It is heated from the outside, and it, in turn, heats the sample inside, ensuring the material is only exposed to a clean, controlled atmosphere, free from any byproducts of the heating process.

Achieving Absolute Temperature Uniformity

Sensitive processes like annealing or sintering require every part of the material to experience the exact same temperature. Hot spots can ruin an entire experiment.

A muffle furnace uses a combination of radiant and convection heat transfer. The chamber walls, typically made of a uniform, heat-resistant ceramic, radiate heat evenly from all sides. This creates a highly homogenous thermal environment, eliminating the temperature gradients that plague other heating methods.

Enabling Precise Temperature Profiles

Many material science applications require not just a static temperature but a dynamic heating and cooling cycle.

Advanced programmable controls allow users to set precise temperature ramps, soaks (holding a specific temperature), and cooling rates. This level of control is essential for studying or creating materials with specific crystalline structures or mechanical properties.

Advanced Atmosphere Control for Reactive Materials

Many materials that are stable at room temperature become highly reactive at the temperatures achieved in a furnace. This is a common challenge for which muffle furnaces offer a direct solution.

The Problem of Oxidation

Exposing certain metals, alloys, or composite materials to oxygen at high temperatures can cause them to oxidize, forming an undesirable surface layer or changing their fundamental properties.

Creating an Inert Environment

To solve this, many muffle furnaces are designed to operate with a protective atmosphere. The chamber can be purged of oxygen and filled with an inert gas like argon or nitrogen.

This capability is critical for heat-treating oxygen-sensitive materials, developing advanced alloys, and working with certain nanomaterials or metallic powders.

Understanding the Trade-offs

While powerful, the design of a muffle furnace introduces certain considerations that are important to understand. Objectivity requires acknowledging these limitations.

Slower Heating and Cooling

The same thermal mass that ensures temperature stability also means muffle furnaces generally heat up and cool down more slowly than direct-heating ovens. This can impact throughput in time-sensitive industrial applications.

Higher Initial Cost

The advanced features—such as durable ceramic muffles, sophisticated programmable controllers, and ports for inert gas—contribute to a higher cost compared to simpler laboratory ovens.

Potential for Thermal Shock

The ceramic muffle itself can be susceptible to thermal shock if temperature changes are too rapid. While robust, they must be operated according to the manufacturer's guidelines to ensure a long service life.

Making the Right Choice for Your Application

The decision to use a muffle furnace should be based on the specific demands of your material and process.

- If your primary focus is analytical purity: Use a muffle furnace for applications like ashing or gravimetric analysis, where preventing any contamination is critical to accurate results.

- If your primary focus is materials science: The furnace's uniform heating and programmable cycles are essential for heat-treatment processes like annealing, sintering, or tempering metals and ceramics.

- If your primary focus is reactive materials: You must use a muffle furnace with inert gas capabilities to prevent the oxidation of sensitive alloys, composites, or powders.

Ultimately, a muffle furnace empowers you to control the thermal environment with unmatched precision, ensuring your results are defined by your process, not by your equipment.

Summary Table:

| Feature | Benefit for Sensitive Materials |

|---|---|

| Isolation Chamber | Prevents contamination from heating elements |

| Uniform Heating | Eliminates hot spots for consistent results |

| Programmable Controls | Allows precise temperature profiles |

| Inert Atmosphere Capability | Protects against oxidation and reactions |

Need a reliable high-temperature furnace for your sensitive materials? KINTEK specializes in advanced solutions like Muffle, Tube, and Vacuum Furnaces, with deep customization to meet your unique lab requirements. Contact us today to enhance your material processing with precision and purity!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing