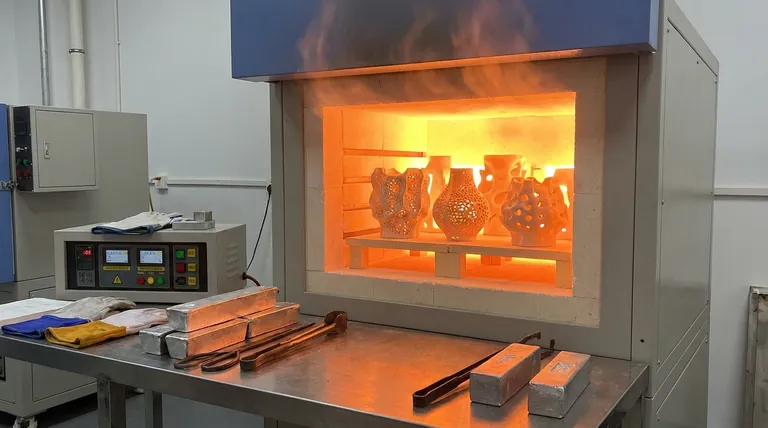

High-temperature sintering is the critical finalization step for ceramic shells, required to convert the mold from a temporary shape into a stable refractory container. This process serves two essential functions: it eliminates any remaining wax from the pattern and triggers a chemical reaction between the ceramic powder and binder to lock in the shell's physical structure.

The sintering process does not just harden the shell; it fundamentally alters its chemistry to create a stable ceramic phase capable of containing high-melting-point alloys without deforming.

The Chemical Transformation

To understand why sintering is non-negotiable, one must look at the chemical changes occurring within the box furnace.

Eliminating Contaminants

Before casting, the shell often contains trace amounts of residual wax from the pattern material.

Sintering in a box furnace burns off these residues completely. This ensures the mold cavity is perfectly clean, preventing defects in the final alloy casting.

The Binder-Powder Reaction

In its "green" (unsintered) state, the shell is essentially just ceramic powder held together by a temporary binding agent.

High temperatures facilitate a necessary reaction between this ceramic powder and the binder. This reaction is the mechanism that transitions the shell from a collection of loose particles into a unified solid.

Formation of a Stable Ceramic Phase

The ultimate goal of the binder-powder reaction is the creation of a "stable ceramic phase."

This phase change creates a material structure that is chemically inert. This prevents the shell from reacting negatively with the molten metal, which is particularly critical when working with reactive, high-melting-point alloys.

Ensuring Physical Integrity

Beyond chemistry, the physical demands placed on a ceramic shell during casting are extreme.

Resistance to Deformation

When high-melting-point alloys are poured, they exert significant thermal and mechanical stress on the mold.

A shell that has not been sintered lacks the rigidity to withstand this stress. Sintering ensures the shell has the physical stability to maintain its shape, preventing bulging or warping during the pour.

Structural Densification

The heat of the box furnace causes the ceramic particles to bond and densify.

This densification provides the structural strength required to prevent shell cracking or total failure (breakout) when the heavy molten metal enters the cavity.

Risks of Insufficient Sintering

Skipping or shortening this process introduces significant risks to the manufacturing workflow.

Chemical Instability

If the stable ceramic phase is not fully formed, the shell remains chemically active.

This can lead to surface reactions with the alloy, resulting in poor surface finish or metallurgical contamination of the final part.

Dimensional Inaccuracy

Without the hardening effects of sintering, the shell remains susceptible to softening under heat.

This leads to casting deformation, where the final metal part does not meet the required dimensional tolerances.

Making the Right Choice for Your Goal

Ensuring your ceramic shells are properly sintered is about balancing process efficiency with part integrity.

- If your primary focus is Dimensional Accuracy: Ensure the sintering cycle is long enough to fully complete the binder-powder reaction, guaranteeing the shell is rigid enough to resist deformation.

- If your primary focus is Metallurgical Purity: Prioritize the box furnace temperature to ensure complete evacuation of residual wax, preventing carbon defects or inclusions in the alloy.

Sintering is not merely a drying step; it is the manufacturing phase that defines the ultimate reliability of your casting system.

Summary Table:

| Feature | Sintering Impact | Benefit for Casting |

|---|---|---|

| Residual Wax | Complete burnout | Prevents defects and inclusions |

| Binder-Powder | Chemical reaction | Creates a unified, solid shell structure |

| Phase Stability | Formation of stable ceramic phase | Prevents chemical reactions with molten metal |

| Physical Integrity | Structural densification | Resists deformation and prevents shell breakout |

| Dimensional Control | Hardening and rigidity | Ensures tight tolerances for final parts |

Elevate Your Casting Precision with KINTEK

Don't let inadequate sintering compromise your metallurgical purity or dimensional accuracy. Backed by expert R&D and manufacturing, KINTEK offers high-performance Box, Muffle, Tube, and Vacuum furnace systems, all fully customizable to meet the rigorous demands of ceramic shell sintering and high-temp material processing. Whether you are casting complex alloys or developing new ceramic phases, our advanced thermal solutions provide the uniform heating and precise control your lab requires.

Ready to optimize your thermal workflow? Contact KINTEK today to discuss your unique needs with our technical team!

References

- Kilian Sandner, Uwe Glatzel. Investment casting of Cr–Si alloys with liquidus temperatures up to 1900 °C. DOI: 10.1007/s40962-024-01490-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- Why is high-temperature calcination necessary for the modification of boron-doped porous carbon? Expert Insights

- How is the muffle furnace designed to ensure uniform and safe heating? Discover Its Precision Engineering

- What personal protective equipment (PPE) is recommended for benchtop furnace use? Ensure Lab Safety with Proper Gear

- What are the general characteristics and advantages of box type resistance furnaces? Discover Versatile Heating Solutions for Your Lab

- Why must high-temperature calcination of ZnO nanoparticles be in a muffle furnace? Ensure Purity and Crystallinity

- Why is an industrial high-temperature furnace required for chemical activation? Achieve 700°C Precision for Carbon

- Why might a muffle furnace have low heating efficiency? Diagnose and Fix Energy Loss Issues