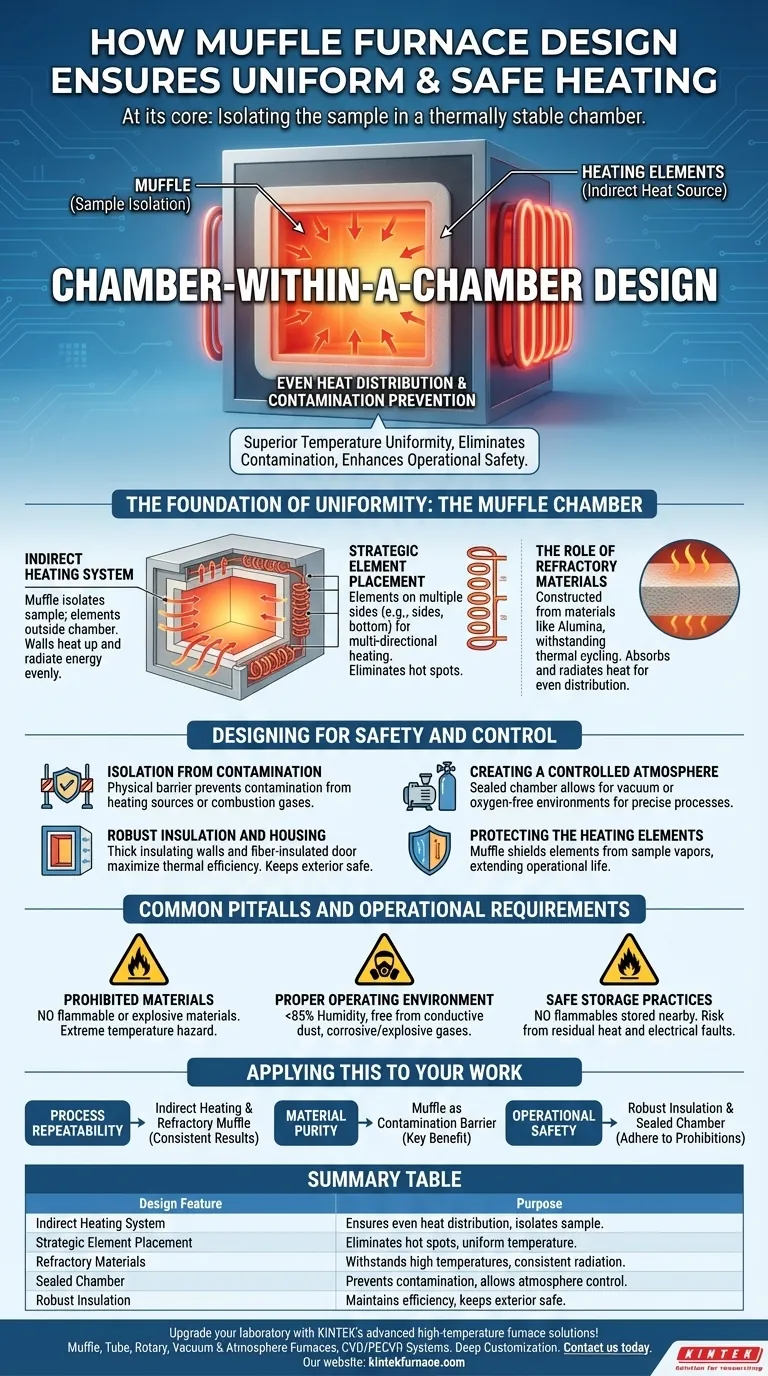

At its core, a muffle furnace is engineered for uniform and safe heating through a specific design principle: isolating the sample in a thermally stable chamber. This "muffle" separates the material from the raw heating elements, allowing heat to be distributed evenly and indirectly while preventing contamination and creating a controlled, secure environment.

The key to a muffle furnace's performance is its "chamber-within-a-chamber" design. By separating the sample from the direct heat source, it achieves superior temperature uniformity, eliminates contamination, and enhances operational safety.

The Foundation of Uniformity: The Muffle Chamber

A muffle furnace's ability to produce consistent results stems directly from the design of its inner chamber, the muffle itself.

An Indirect Heating System

The muffle is a distinct inner chamber that houses the sample. The heating elements are positioned outside this chamber, typically on the sides.

This design means the sample is not exposed to the direct, intense radiation of the coils. Instead, the chamber walls heat up and radiate that energy evenly throughout the interior.

Strategic Element Placement

To ensure rapid and even heating, open coil heating elements are often placed on multiple sides of the muffle chamber.

This multi-directional heating approach is critical for eliminating temperature gradients—or "hot spots"—that could otherwise compromise the integrity of the process.

The Role of Refractory Materials

The muffle is constructed from refractory materials, such as alumina, which are chosen for their ability to withstand extreme thermal cycling.

These materials are excellent at absorbing and radiating heat, further contributing to the even distribution of temperature across the entire sample.

Designing for Safety and Control

Beyond temperature uniformity, the muffle furnace is engineered to provide a secure and controlled operating environment.

Isolation from Contamination

By physically separating the sample from the heating source (which could be combustion-based in some models), the muffle design prevents contamination.

This is crucial for applications where chemical purity is paramount, as it ensures no external gases or byproducts interfere with the material being heated.

Creating a Controlled Atmosphere

The sealed nature of the muffle chamber allows for precise control over the internal environment. This makes it possible to conduct processes in a vacuum or an oxygen-free atmosphere.

Robust Insulation and Housing

Muffle furnaces feature thick insulating walls and a fiber-insulated door to maximize thermal efficiency and safety. This minimizes heat loss and keeps the exterior housing, typically made of stainless steel, cool enough to be safe.

Protecting the Heating Elements

The design also works in reverse. The muffle shields the delicate heating elements from any vapors or byproducts released by the sample during heating, significantly extending the furnace's operational life.

Common Pitfalls and Operational Requirements

To leverage the furnace's design benefits, you must adhere to strict operational parameters. Misuse can negate its safety features and damage the equipment.

Prohibited Materials

Under no circumstances should flammable or explosive materials be placed inside a muffle furnace. The extreme temperatures create an obvious and significant hazard.

Proper Operating Environment

The furnace must operate in a specific environment to function correctly and safely. This includes a relative humidity of less than 85% and an atmosphere free from conductive dust, corrosive gases, or explosive gases.

Safe Storage Practices

Flammable or volatile materials should never be stored near the furnace, even when it is not in use. The residual heat and the potential for electrical faults present a constant risk.

Applying This to Your Work

Understanding the furnace's design empowers you to use it effectively for your specific goal.

- If your primary focus is process repeatability: The even heat distribution from the indirect heating system and refractory muffle is the most critical feature for ensuring consistent results.

- If your primary focus is material purity: The muffle's role as a barrier against contamination from heating elements or combustion gases is the key design benefit.

- If your primary focus is operational safety: Rely on the robust insulation and the sealed chamber design, but always adhere to the strict environmental and material prohibitions.

By appreciating how these design elements work together, you can confidently achieve precise, safe, and reliable high-temperature processing.

Summary Table:

| Design Feature | Purpose |

|---|---|

| Indirect Heating System | Ensures even heat distribution by isolating sample from direct heat sources |

| Strategic Element Placement | Eliminates hot spots for uniform temperature across the chamber |

| Refractory Materials | Withstands high temperatures and aids in consistent heat radiation |

| Sealed Chamber | Prevents contamination and allows control of atmosphere (e.g., vacuum) |

| Robust Insulation | Maintains thermal efficiency and keeps exterior safe to touch |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for uniform and safe heating. Contact us today to discuss how our solutions can enhance your process efficiency and reliability!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination