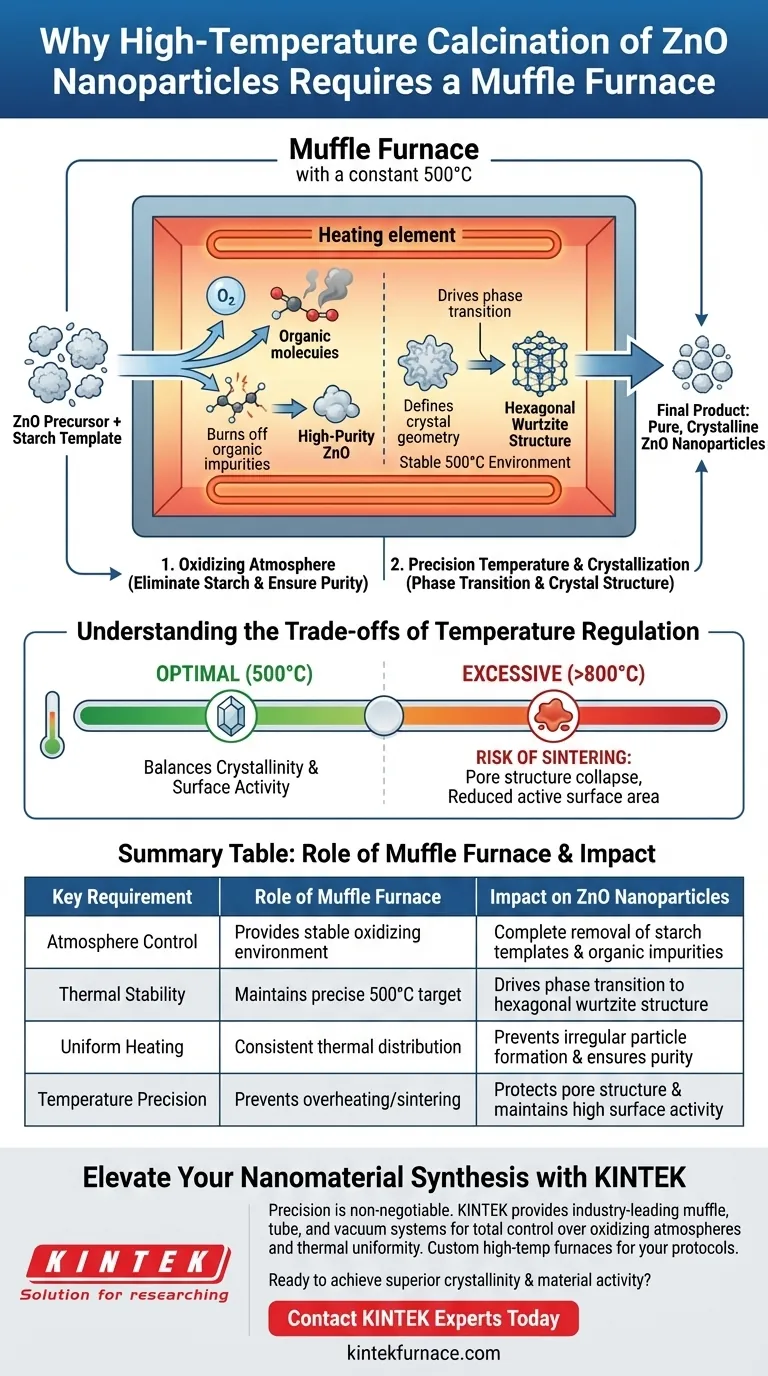

High-temperature calcination in a muffle furnace is strictly required to ensure the simultaneous removal of organic templates and the precise crystallization of the final product. Specifically, it provides a stable, oxidizing environment around 500°C that enables zinc species to undergo phase transition while chemically decomposing starch templates to leave behind pure Zinc Oxide (ZnO).

The muffle furnace acts as a dual-function reactor: it burns off organic impurities through controlled oxidation while maintaining the rigorous thermal stability needed to grow the specific hexagonal wurtzite crystal structure characteristic of high-quality ZnO.

The Critical Role of the Oxidizing Atmosphere

Eliminating the Starch Template

The primary challenge in synthesizing ZnO nanoparticles involves removing the organic framework used during formation. The muffle furnace provides the necessary oxidizing atmosphere to systematically decompose the starch template.

Ensuring Chemical Purity

Without a continuous supply of oxygen at high temperatures, organic residues would contaminate the final material. The furnace ensures the complete elimination of residual organic matter, resulting in a high-purity crystalline product.

Precision Temperature Control and Crystallization

Facilitating Phase Transition

The transformation of precursor materials into final oxides is a thermodynamic process. The muffle furnace maintains a constant temperature (typically 500°C) which drives the zinc species to complete their phase transition effectively.

Defining the Crystal Structure

Temperature stability is directly linked to crystal geometry. The superior temperature control accuracy of the muffle furnace ensures that ZnO crystals grow according to a strict hexagonal wurtzite structure.

Uniform Thermal Environment

Beyond just reaching temperature, the environment must be uniform. A stable thermal environment ensures that precursors react fully and consistently, preventing the formation of irregular or amorphous particles.

Understanding the Trade-offs of Temperature Regulation

The Risk of Sintering

While high heat is necessary, excessive temperatures can be detrimental. If the furnace temperature is set too high (e.g., approaching 800°C), it can lead to severe sintering, causing the pore structure to collapse and reducing the material's active surface area.

Balancing Crystallinity and Activity

There is a delicate balance between forming strong crystals and maintaining surface activity. Accurate temperature regulation is the primary method for balancing material crystallinity with surface oxygen vacancies and adsorption activity.

Making the Right Choice for Your Goal

To optimize your ZnO synthesis, align your furnace parameters with your specific material requirements:

- If your primary focus is High Purity: Prioritize the oxidizing atmosphere capabilities of the furnace to ensure the starch template is fully decomposed.

- If your primary focus is Crystal Structure: Focus on the temperature control accuracy to ensure the stable growth of the hexagonal wurtzite phase without overheating.

Success in ZnO calcination relies on leveraging the muffle furnace not just as a heater, but as a precision instrument for chemical purification and structural engineering.

Summary Table:

| Key Requirement | Role of Muffle Furnace | Impact on ZnO Nanoparticles |

|---|---|---|

| Atmosphere Control | Provides stable oxidizing environment | Complete removal of starch templates & organic impurities |

| Thermal Stability | Maintains precise 500°C target | Drives phase transition to hexagonal wurtzite structure |

| Uniform Heating | Consistent thermal distribution | Prevents irregular particle formation and ensures purity |

| Temperature Precision | Prevents overheating/sintering | Protects pore structure and maintains high surface activity |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is non-negotiable when engineering hexagonal wurtzite structures and high-purity ZnO. KINTEK provides industry-leading muffle, tube, and vacuum systems designed to give you total control over oxidizing atmospheres and thermal uniformity. Backed by expert R&D and manufacturing, our high-temp lab furnaces are fully customizable to meet your unique calcination protocols.

Ready to achieve superior crystallinity and material activity?

Visual Guide

References

- Roumaissa Djafarou, Tarek Hidouri. Starch-Assisted Eco-Friendly Synthesis of ZnO Nanoparticles: Enhanced Photocatalytic, Supercapacitive, and UV-Driven Antioxidant Properties with Low Cytotoxic Effects. DOI: 10.3390/ijms26020859

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What should be considered about crucible size when choosing a muffle furnace? Optimize for Safety and Efficiency

- Why is an industrial high-temperature furnace required for chemical activation? Achieve 700°C Precision for Carbon

- How is a laboratory high-temperature muffle furnace utilized to achieve the specific crystalline structure of LaFeO3 catalysts?

- What is the role of a laboratory high-temperature muffle furnace in the pretreatment of peat clay? Unlock Reactivity

- How is a muffle furnace applied to determine glass fiber content in GFPP? Precision Calcination Explained

- What PPE should be worn during maintenance and repairs of a benchtop furnace? Essential Gear for Your Safety

- How should samples be handled when using a muffle furnace? Ensure Accurate and Safe Heat Treatment

- How does a muffle furnace contribute to the post-processing of SnO2? Engineering Superior Nanoparticle Crystallinity