At a minimum, maintenance on a benchtop furnace requires heat-resistant gloves, safety glasses or goggles, and appropriate protective clothing. Depending on the specific task, this may be supplemented with a face shield for full-face protection and respiratory protection if there is a risk of inhaling dust or fumes. This gear is not optional; it is your primary defense against thermal, mechanical, and electrical hazards.

Your choice of PPE should not be based on a generic checklist, but on a direct assessment of the task at hand. The fundamental goal is to create a barrier between you and every potential hazard, from the obvious intense heat to the less obvious risks of airborne particles and electrical shock.

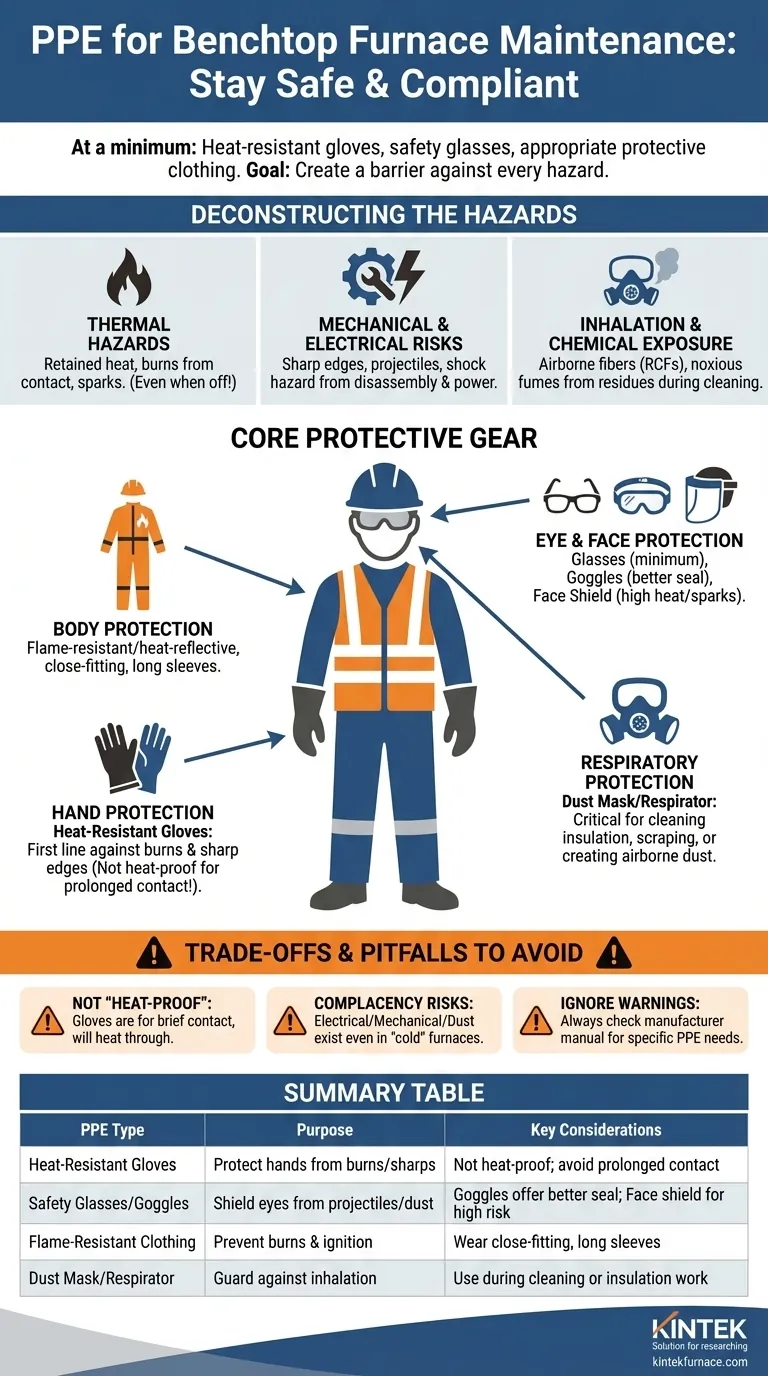

Deconstructing the Hazards of Furnace Maintenance

To select the right PPE, you must first understand the specific dangers you face. A benchtop furnace presents multiple, distinct types of risk, even when powered down.

The Obvious Danger: Thermal Hazards

Even after a furnace is turned off, it retains significant heat for a long time. Direct contact with the furnace body, door, or internal components can cause severe burns. Handling recently heated materials or dealing with sparks also falls into this category.

The Hidden Dangers: Mechanical and Electrical Risks

Maintenance often involves disassembling parts, which can create sharp edges or release small projectiles. During cleaning, scraping old insulation or deposits can send debris flying. Furthermore, as an electrical appliance, there is always an underlying risk of shock if the unit is not properly de-energized.

The Invisible Dangers: Inhalation and Chemical Exposure

Furnace insulation, particularly in older models, can release airborne refractory ceramic fibers (RCFs) when disturbed. These are a serious respiratory hazard. Likewise, cleaning agents or residues burning off inside the furnace can create noxious fumes that should not be inhaled.

Selecting Your Core Protective Gear

Each piece of PPE is designed to counter a specific hazard identified above. Using them in combination provides comprehensive protection.

Hand Protection: Heat-Resistant Gloves

This is your first line of defense against burns. Heat-resistant gloves are essential for handling any part of the furnace that is or was recently hot. They also provide a layer of protection against sharp edges during mechanical repairs.

Eye and Face Protection: Glasses, Goggles, and Shields

Safety glasses are the absolute minimum to protect against unexpected projectiles. Goggles offer a better seal, providing superior protection against dust and splashes. For tasks involving high heat, sparks, or significant debris, a face shield worn over safety glasses is the correct choice to protect your entire face.

Body Protection: Flame-Resistant Clothing

Regular clothing can melt or ignite when exposed to high heat or sparks. Flame-resistant or heat-reflective clothing is critical. It should be close-fitting to avoid snagging on equipment, and long sleeves are necessary to protect your arms from burns and scrapes.

Respiratory Protection: When Dust Masks Are Critical

This protection is task-dependent but non-negotiable when needed. Use a dust mask or respirator when cleaning out old insulation, scraping internal surfaces, or performing any action that could create airborne dust or fibers.

Understanding the Trade-offs and Common Pitfalls

True safety comes from understanding the limits of your equipment and avoiding complacency.

"Heat-Resistant" Is Not "Heat-Proof"

Remember that heat-resistant gloves are designed for intermittent, brief contact with hot surfaces. They are not intended for holding hot items for extended periods and will eventually heat through, leading to burns.

The Risk of Complacency with a "Cold" Furnace

Many accidents happen when a furnace is assumed to be safe because it's cool. Always remember that electrical hazards persist until the unit is physically unplugged. Mechanical risks from sharp edges and respiratory risks from dust exist regardless of the furnace's temperature.

Ignoring Manufacturer-Specific Warnings

Always read the furnace's operating manual. The manufacturer will provide specific safety warnings and may recommend particular types of PPE based on the materials used in its construction, such as the type of insulation.

Beyond PPE: Creating a Safe Work Environment

PPE is your last line of defense. The first line is a safe environment and a clear plan.

Emergency Preparedness is Non-Negotiable

Keep a fire extinguisher rated for electrical fires (Type C) within easy reach. Ensure a smoke detector is operational in the area. Most importantly, you and everyone in the vicinity must know the emergency shutdown procedure for the furnace before any work begins.

Maintain a Clear and Uncluttered Workspace

Keep the area around the furnace free of flammable materials, tripping hazards, and unnecessary clutter. A clean workspace allows you to move safely and respond quickly in an emergency.

Matching Your PPE to the Task at Hand

Use this as a guide to make an informed decision for your specific maintenance scenario.

- If your primary focus is a routine visual inspection on a cold, de-energized furnace: Basic safety glasses and gloves to protect from sharp edges are sufficient.

- If you are replacing insulation or cleaning internal components (cold): Wear sealed goggles, gloves, and a suitable dust mask or respirator to protect against airborne particles.

- If you are troubleshooting or performing repairs on a recently operated (hot) furnace: Use the complete set of gear: heat-resistant gloves, a face shield over safety glasses, and flame-resistant clothing.

Ultimately, safety is a deliberate practice, not an automatic outcome.

Summary Table:

| PPE Type | Purpose | Key Considerations |

|---|---|---|

| Heat-Resistant Gloves | Protect hands from burns and sharp edges | Not heat-proof; avoid prolonged contact |

| Safety Glasses/Goggles | Shield eyes from projectiles and dust | Goggles offer better seal; use face shield for high-risk tasks |

| Flame-Resistant Clothing | Prevent burns and ignition | Wear close-fitting, long sleeves |

| Dust Mask/Respirator | Guard against inhalation of dust and fumes | Use during cleaning or insulation work |

Ensure your lab's safety with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today for expert guidance and reliable equipment!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is a laboratory muffle furnace used in 3D-printed PP-CF cross-linking? Achieve Thermal Stability at 150 °C

- What is the primary purpose of using a high-temperature box resistance furnace during the pretreatment of kaolin catalysts? Optimize Performance & Structure

- What are some major applications of muffle furnaces in research and industry? Unlock Precision Heat for Your Lab

- What are the technical advantages of using an infrared heating furnace for the fast pyrolysis of cellulose? Higher Yields

- Why is a laboratory high-temperature box furnace essential for komatiite glass? Achieve 1530°C Precision

- What is the significance of a high-temperature muffle furnace in CaO powder modification? Unlock Precise Crystallinity

- Why is annealing in a 600 Celsius muffle furnace critical for ZnCo2O4? Unlock High-Performance Spinel Catalysts

- How does an elevator high-temperature furnace ensure process efficiency? Optimize S53P4 Bioactive Glass Production