To properly handle samples in a muffle furnace, you must place them in high-temperature resistant containers like porcelain crucibles, position them centrally within the furnace for even heating, and use crucible tongs for safe insertion and removal. Strict control over temperature ramps and careful handling are essential to prevent damage to both your sample and the furnace itself.

The primary goal of sample handling is to maintain a controlled, clean, and thermally stable environment. Every step—from choosing a crucible to opening the door—is designed to protect the sample from contamination and the furnace from thermal shock and chemical corrosion, ensuring both accurate results and equipment longevity.

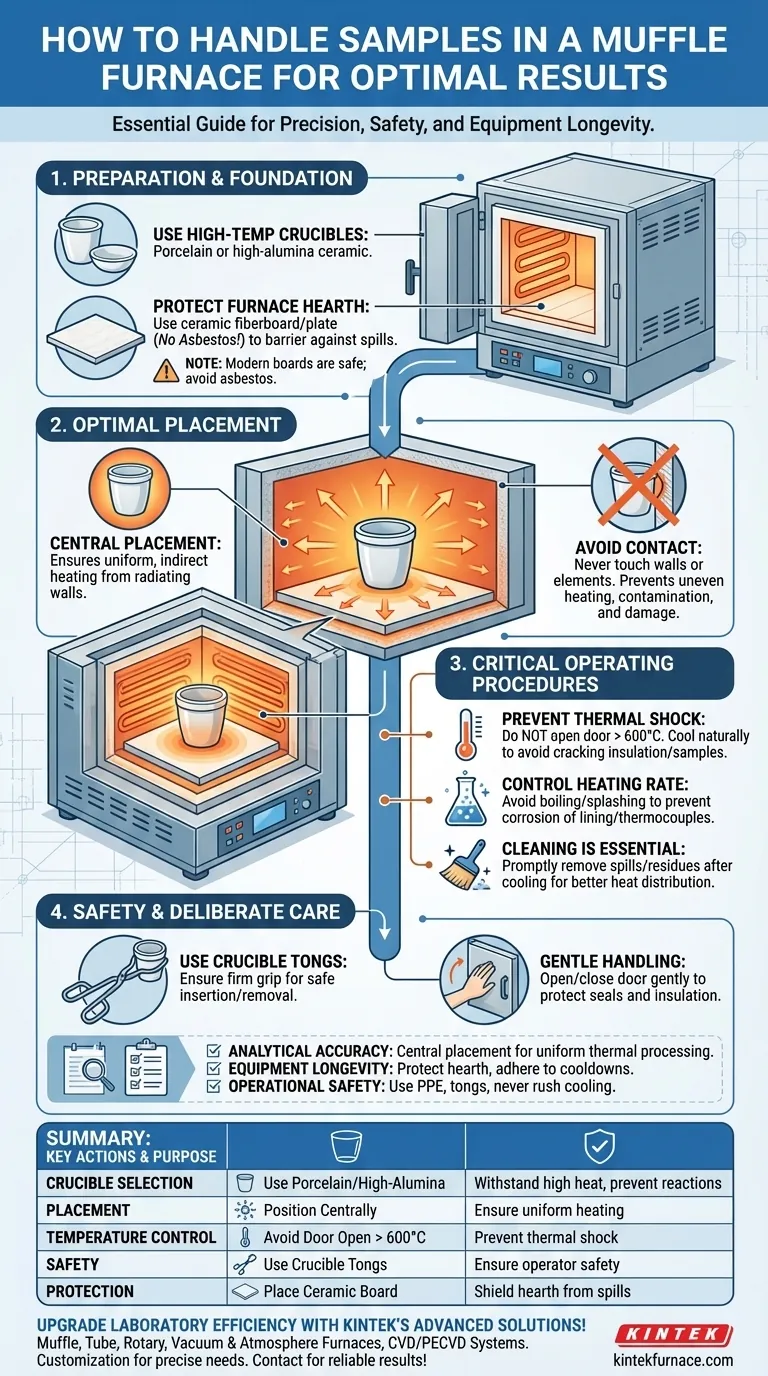

The Foundation: Preparing the Crucible and Furnace

This initial stage sets the groundwork for a successful and safe heating cycle.

Use High-Temperature Crucibles

Samples must be placed in containers designed to withstand extreme heat without reacting, melting, or cracking.

Porcelain or high-alumina ceramic crucibles and dishes are the industry standard for this purpose.

Protect the Furnace Hearth

Place a protective layer, such as a ceramic fiberboard or high-alumina plate, on the furnace floor before inserting your samples.

This board acts as a crucial barrier, protecting the hearth from accidental spills that can corrode or permanently bond to the furnace floor at high temperatures.

Note: Older guidelines may mention asbestos boards. Asbestos is a hazardous material and must not be used. Modern ceramic boards are the safe and effective alternative.

Achieving Uniform Heating and Accurate Results

Placement is not arbitrary; it is a key variable in achieving repeatable outcomes.

The Importance of Central Placement

Place your crucibles neatly in the center of the furnace hearth, away from the walls.

A muffle furnace works by indirect heating, with elements warming the chamber walls, which then radiate heat inwards. Central placement ensures your sample receives the most uniform heat possible from all sides.

Avoid Contact with Furnace Components

Never allow your sample or crucible to touch the furnace walls or the visible heating elements.

Direct contact can lead to uneven heating, potential sample contamination, and electrical or physical damage to the sensitive heating elements.

Critical Operating Procedures and Common Pitfalls

How you operate the furnace during the cycle is as important as the setup. Ignoring these rules is the most common cause of equipment failure.

Preventing Thermal Shock

The most common mistake is opening the furnace door while the temperature is extremely high. A sudden influx of cool ambient air will cause thermal shock.

This rapid temperature change can easily crack the furnace's ceramic insulation or even shatter your crucible and sample.

As a firm rule, do not open the door if the internal temperature is above 600°C. Always wait for the furnace to cool down naturally.

The Risk of Splashing and Corrosion

Control your heating rate carefully, especially with volatile samples, to prevent them from boiling or splashing out of the crucible.

Spilled material can chemically attack the furnace lining and the thermocouple sheath, leading to costly damage and inaccurate temperature readings.

Cleaning Is Not Optional

Promptly and thoroughly clean any spills, slag, or residues after the furnace has fully cooled. A clean furnace ensures better heat distribution and prevents cross-contamination between samples.

Handle with Deliberate Care

Always use long, sturdy crucible tongs to insert and remove samples, ensuring a firm grip to prevent drops.

Open and close the furnace door gently. Slamming it can damage the door seal or crack the brittle internal insulation components over time.

How to Apply This to Your Goal

Your specific priorities will determine which procedures to emphasize.

- If your primary focus is analytical accuracy: Prioritize placing the sample perfectly in the center of the furnace to guarantee the most uniform thermal processing.

- If your primary focus is equipment longevity: Emphasize protecting the hearth with a ceramic plate and strictly adhering to cooldown procedures to prevent thermal shock.

- If your primary focus is operational safety: Always use the correct personal protective equipment (PPE) and crucible tongs, and never rush the cooling process or attempt to handle components at high heat.

By treating the muffle furnace as a precision instrument, your handling procedures will ensure reliable results and safe operation for years to come.

Summary Table:

| Handling Step | Key Action | Purpose |

|---|---|---|

| Crucible Selection | Use porcelain or high-alumina ceramic crucibles | Withstand high heat, prevent reactions |

| Placement | Position centrally on hearth | Ensure uniform heating |

| Temperature Control | Avoid opening door above 600°C | Prevent thermal shock |

| Safety | Use crucible tongs for handling | Ensure operator safety |

| Protection | Place ceramic board on furnace floor | Shield hearth from spills |

Upgrade your laboratory efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Ensure precise, contamination-free sample handling and extend equipment life—contact us today for a tailored solution that delivers reliable results and long-term value!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency