When selecting a muffle furnace, your crucible's dimensions directly determine the minimum required size of the furnace's internal chamber. You must ensure the chamber can accommodate the crucible with sufficient clearance on all sides for safe handling and uniform heating. However, the crucible itself is just one step in a larger decision-making process that begins with your sample.

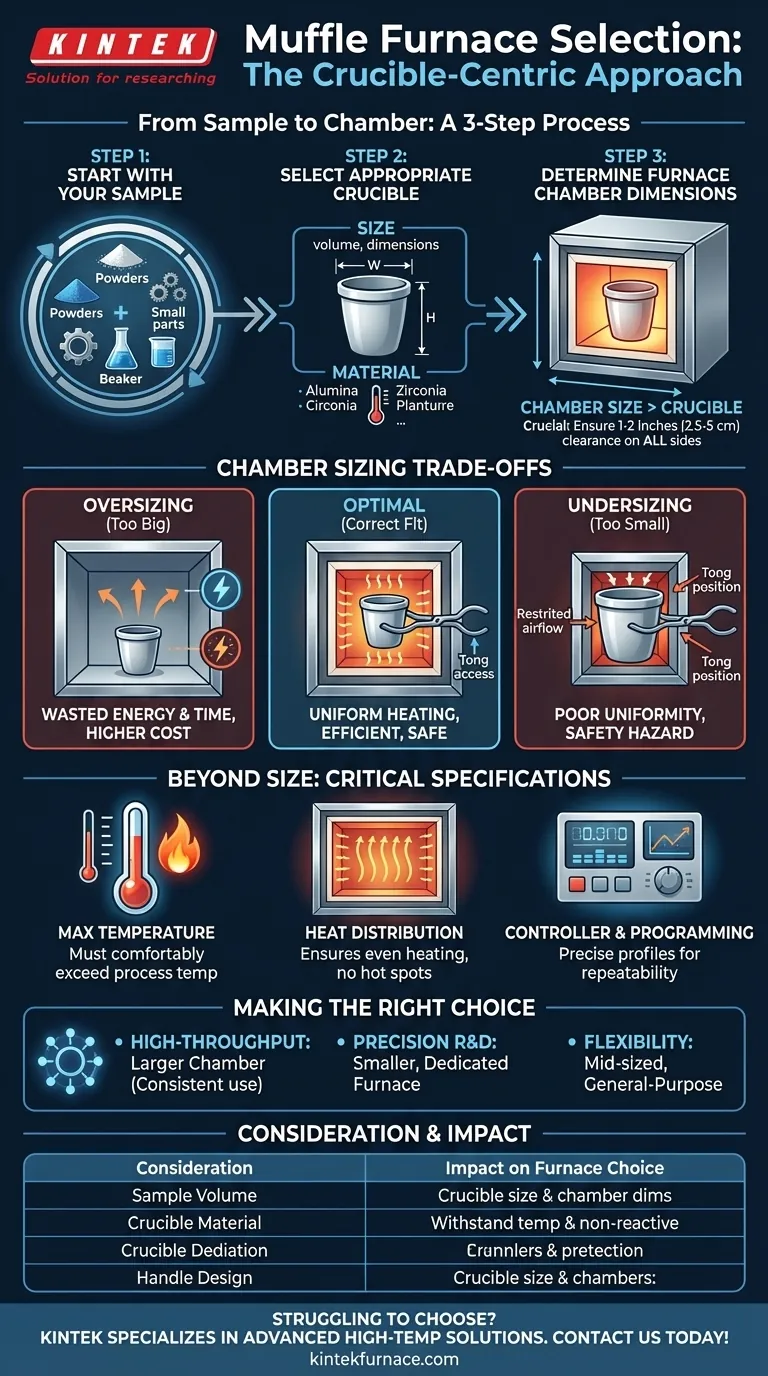

The central mistake is choosing a furnace based on its listed capacity alone. The correct approach is a three-step process: your sample's requirements dictate the crucible size and material, which in turn defines the necessary furnace chamber dimensions and temperature capabilities.

The Foundational Principle: From Sample to Chamber

Thinking about the furnace chamber first is working backward. The most effective selection process begins with the object being heated and works its way outward.

Step 1: Start with Your Sample

The absolute starting point is the material you need to process. The volume, dimensions, and number of samples you intend to run in a single cycle are the primary constraints.

This initial analysis dictates the minimum internal volume your crucible must have.

Step 2: Select the Appropriate Crucible

Once you know the sample requirements, you can choose a crucible. This decision has two components: size and material.

The crucible must be large enough to contain your sample safely. Crucially, the crucible's material must be able to withstand your target processing temperature and remain non-reactive with your sample material. For example, alumina is excellent for many alloys, while zirconia is required for reactive metals or ultra-high temperatures exceeding 2100°C.

Step 3: Determine Required Furnace Chamber Dimensions

With the crucible selected, you can now define the furnace chamber size. The chamber must be larger than the crucible. A tight fit is a significant operational and safety flaw.

You need adequate clearance—typically 1-2 inches (2.5-5 cm) on all sides—to allow for uniform air circulation and to provide room for tongs to safely place and retrieve the crucible without touching the hot chamber walls.

Understanding the Trade-offs of Chamber Sizing

Choosing a furnace that is "big enough" is not the optimal strategy. The chamber size relative to your crucible has direct impacts on performance, efficiency, and safety.

The Cost of Oversizing: Wasted Energy and Time

A furnace chamber that is significantly larger than your crucible is inefficient. The furnace must expend more energy and time to heat the excess empty space.

This leads to higher operational costs and longer cycle times, decreasing lab productivity.

The Risk of Undersizing: Poor Performance and Safety

A chamber that is too small is even more problematic. A cramped crucible restricts airflow, leading to poor temperature uniformity and inconsistent results.

More importantly, it creates a serious safety hazard. Attempting to maneuver tongs in a tight space dramatically increases the risk of dropping the crucible, spilling its contents, or suffering severe burns from contact with the heating elements or insulation.

Future-Proofing vs. Specialization

Consider your future needs. If you anticipate processing larger samples or multiple batches, a larger furnace might seem wise. However, consistently using a large furnace for small jobs is highly inefficient.

It is often better to have a properly sized furnace for your primary task and access to a different furnace for occasional, non-standard jobs.

Beyond Size: Critical Furnace Specifications

While the chamber dimension is a direct consequence of your crucible choice, other furnace features are equally critical for a successful process.

Maximum Temperature Capability

The furnace's maximum operating temperature must comfortably exceed your required processing temperature. This ensures the heating elements are not constantly running at their absolute limit, which extends their lifespan. This capability must also align with your chosen crucible material.

Heat Distribution and Uniformity

The quality and placement of heating elements determine how evenly your crucible is heated. A furnace with poor uniformity can create hot and cold spots on your sample, compromising the integrity of your results.

Controller and Programming

A precise digital controller allows you to execute specific heating and cooling profiles accurately. This is essential for protecting sensitive samples and ensuring the process is repeatable, which is the cornerstone of reliable scientific and industrial work.

Making the Right Choice for Your Application

Answering the following questions will guide you to the correct furnace for your specific operational goals.

- If your primary focus is high-throughput production: A larger chamber that can safely hold multiple crucibles may be the most efficient choice, provided it is utilized consistently.

- If your primary focus is precision R&D: A smaller, dedicated furnace that is perfectly matched to your typical crucible size will provide superior temperature uniformity and efficiency.

- If your primary focus is flexibility for varied tasks: A mid-sized, general-purpose furnace offers a compromise, but be aware it will never be perfectly optimized for very small or very large loads.

By starting with your sample, you ensure every subsequent choice—from crucible to furnace—is optimized for efficiency, safety, and repeatable results.

Summary Table:

| Consideration | Impact on Furnace Choice |

|---|---|

| Sample Volume | Determines crucible size and furnace chamber dimensions |

| Crucible Material | Must withstand temperature and be non-reactive with sample |

| Chamber Clearance | Ensures safe handling and uniform heating (1-2 inches recommended) |

| Oversizing | Leads to wasted energy and longer cycle times |

| Undersizing | Causes poor temperature uniformity and safety hazards |

| Future Needs | Balance between specialization and flexibility for varied tasks |

Struggling to choose the right muffle furnace for your crucible needs? At KINTEK, we specialize in providing advanced high-temperature furnace solutions tailored to your unique requirements. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental goals, enhancing efficiency, safety, and repeatability. Don't compromise on performance—contact us today to discuss how we can optimize your lab setup!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO