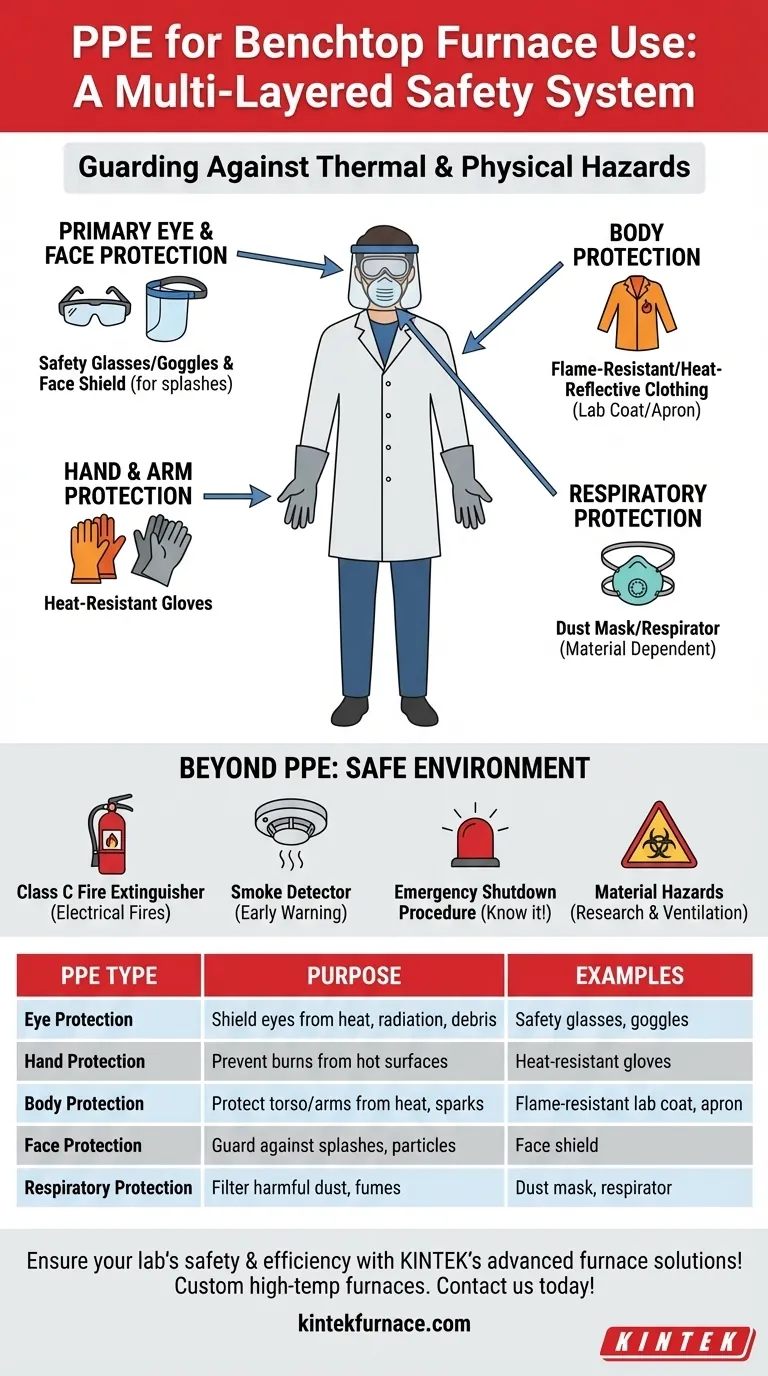

At a minimum, operating a benchtop furnace requires a core set of personal protective equipment (PPE) to guard against significant thermal and physical hazards. This includes safety glasses or goggles for eye protection, heat-resistant gloves for hands, and flame-resistant clothing to shield your body. Depending on the specific application, a face shield and respiratory protection may also be necessary.

Your goal is not merely to wear PPE, but to create a multi-layered system of protection. Each piece of equipment addresses a specific hazard, and when combined with a safe operating environment, it drastically reduces the risk of serious injury.

A Layered Approach to Furnace Safety

True safety comes from understanding the distinct risks involved and selecting the appropriate barrier for each. A benchtop furnace presents hazards from extreme heat, infrared radiation, potential sparks or splashes of molten material, and possibly harmful airborne particles.

Primary Eye and Face Protection

Your eyes are extremely vulnerable to heat, radiation, and flying debris. Safety glasses or goggles are the absolute minimum requirement and should be worn at all times when the furnace is in operation.

For tasks involving higher temperatures or the potential for molten material to splash, a face shield worn over your safety glasses provides a critical secondary layer of protection for your entire face.

Hand and Arm Protection from Extreme Heat

Direct contact with hot surfaces or materials is a primary cause of injury. Heat-resistant gloves are essential for handling any items being placed into or removed from the furnace.

Ensure the gloves are rated for a temperature significantly higher than your furnace's operating temperature. Standard work gloves offer no protection from this level of heat.

Shielding Your Body from Burns

Everyday clothing, especially synthetics like polyester, can melt and cause severe burns if exposed to high heat or sparks. Flame-resistant or heat-reflective clothing, such as a lab coat or apron made from appropriate materials, should be worn to protect your torso and arms.

This barrier prevents accidental contact burns and protects you from the intense radiant heat emitted by the furnace opening.

When Respiratory Protection is Critical

The need for respiratory protection is entirely dependent on the materials you are heating. Many materials can release dust, fumes, or vapors when heated, which can be toxic or damaging to your lungs.

If you are working with powders, binders that burn off, or materials known to off-gas, a dust mask or a respirator is required. Always consult the material safety data sheet (MSDS) for the specific substances you are using to determine the appropriate level of respiratory protection.

Beyond PPE: Creating a Safe Operating Environment

Personal protective equipment is your last line of defense. Your first line of defense is a well-prepared workspace and a clear understanding of emergency procedures.

The Importance of a Fire Extinguisher

A benchtop furnace is an electrical appliance that operates at extreme temperatures. A fire extinguisher suitable for electrical fires (Class C) must be located within easy reach of the workstation.

Early Warning and Emergency Procedures

Install a smoke detector in the room where the furnace is located. More importantly, every operator must know the emergency shutdown procedure for the furnace before ever turning it on. This can prevent a minor issue from escalating into a major incident.

Common Pitfall: Ignoring Material Hazards

One of the most common mistakes is focusing only on the heat from the furnace itself. The materials you place inside it can introduce entirely new chemical and respiratory hazards. Failing to research your materials and use appropriate ventilation or respiratory protection is a significant oversight.

Selecting PPE for Your Specific Task

Use this guide to select the right level of protection based on your work.

- If your primary focus is basic heating of stable, solid materials: Always wear safety glasses, heat-resistant gloves, and flame-resistant clothing as a baseline.

- If your work involves molten materials or high-temperature powders: Add a full face shield to your baseline PPE to protect against splashes and airborne particles.

- If you are heating materials that may off-gas, smoke, or create dust: You must supplement your standard PPE with the appropriate respiratory protection, such as a dust mask or respirator.

Ultimately, proactive planning is the foundation of a safe and successful outcome.

Summary Table:

| PPE Type | Purpose | Examples |

|---|---|---|

| Eye Protection | Shield eyes from heat, radiation, debris | Safety glasses, goggles |

| Hand Protection | Prevent burns from hot surfaces | Heat-resistant gloves |

| Body Protection | Protect torso and arms from heat, sparks | Flame-resistant lab coat, apron |

| Face Protection | Guard against splashes, particles | Face shield |

| Respiratory Protection | Filter harmful dust, fumes | Dust mask, respirator |

Ensure your lab's safety and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how our products can enhance your safety protocols and experimental outcomes!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals