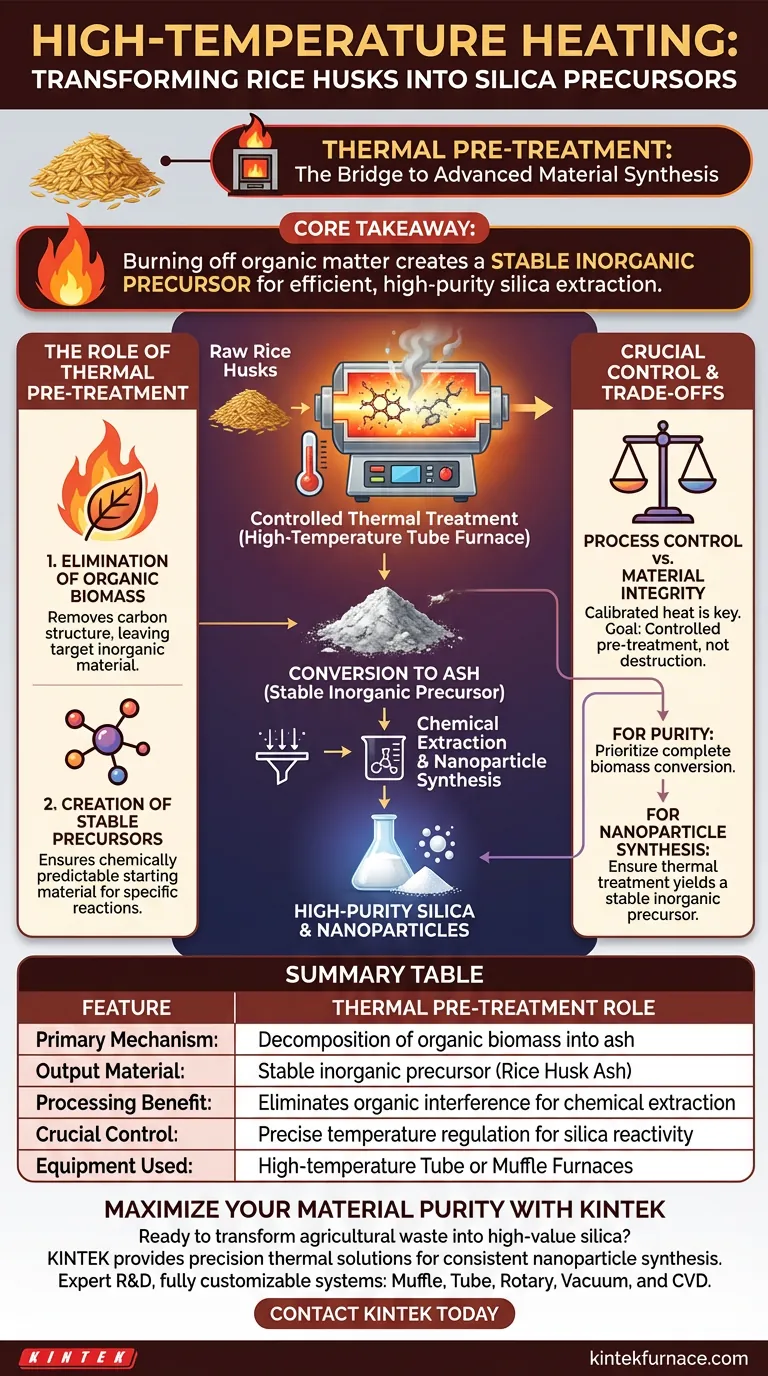

High-temperature heating acts as a critical purification mechanism that fundamentally alters the chemical composition of rice husk raw materials. By subjecting the husks to controlled thermal treatment, the process decomposes complex organic biomass and converts it into ash, effectively isolating the inorganic components needed for silica extraction.

Core Takeaway Thermal pre-treatment is the bridge between raw agricultural waste and advanced material synthesis. By burning off organic matter to create a stable inorganic precursor, high-temperature heating ensures the material is chemically prepared for the efficient extraction of high-purity silica and subsequent nanoparticle synthesis.

The Role of Thermal Pre-treatment

Elimination of Organic Biomass

Rice husks are a composite material containing both organic compounds and inorganic silica. The primary function of high-temperature heating is to facilitate the conversion of organic biomass into ash.

This thermal degradation acts as a filtration step. It removes the carbon-based organic structure that would otherwise interfere with chemical extraction, leaving behind the target inorganic material.

Creation of Stable Precursors

For successful nanoparticle synthesis, the starting material must be chemically predictable. Thermal treatment ensures the remaining ash is a stable inorganic precursor.

This stability provides the necessary reaction conditions for subsequent processing. It ensures that when chemical agents are introduced later, they react specifically with the silica rather than residual organic biological matter.

Precision through Controlled Environments

To achieve high-purity results, this heating process cannot be random; it requires controlled temperatures.

Advanced equipment, such as high-temperature tube furnaces, allows for precise environmental regulation. While often used for complex phase transformations (such as annealing MoS2), in the context of rice husks, this equipment ensures the thermal environment is consistent enough to yield a uniform precursor.

Understanding the Trade-offs

Process Control vs. Material Integrity

While high heat is necessary to remove organics, the temperature must be carefully calibrated. The goal is controlled pre-treatment, not uncontrolled destruction.

If the temperature is uncontrolled, you risk altering the phase of the silica or trapping impurities. The heating profile must be sufficient to fully convert the biomass to ash without compromising the reactivity of the silica for the next stage of extraction.

Making the Right Choice for Your Goal

The application of heat is not just about burning waste; it is about preparing a substrate for advanced chemistry.

- If your primary focus is Purity: Prioritize complete conversion of biomass to ash to ensure no organic contaminants interfere with the chemical extraction.

- If your primary focus is Nanoparticle Synthesis: Ensure the thermal treatment results in a stable inorganic precursor, as this stability is required for the consistent formation of nanoparticles.

High-temperature heating is the defining step that transforms rice husks from agricultural byproduct into a viable resource for advanced silica production.

Summary Table:

| Feature | Thermal Pre-treatment Role |

|---|---|

| Primary Mechanism | Decomposition of organic biomass into ash |

| Output Material | Stable inorganic precursor (Rice Husk Ash) |

| Processing Benefit | Eliminates organic interference for chemical extraction |

| Crucial Control | Precise temperature regulation to maintain silica reactivity |

| Equipment Used | High-temperature Tube or Muffle Furnaces |

Maximize Your Material Purity with KINTEK

Ready to transform agricultural waste into high-value silica? KINTEK provides the precision thermal solutions necessary for consistent nanoparticle synthesis. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research or production needs.

Take the next step in advanced material synthesis. Contact KINTEK today to find the ideal high-temperature furnace for your laboratory.

Visual Guide

References

- Sohan Thombare, C.D. Lokhande. Synthesis and characterization of crystalline cristobalite alpha low silicon dioxide nanoparticles: a cost-effective anode for lithium-ion battery. DOI: 10.1007/s10854-024-13153-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of a laboratory electric drying oven in ACBP production? Ensure Precise Pre-treatment

- How does heat treatment at 500°C affect Ni-Ti shape memory alloys? Optimize Material Performance and Uniformity

- How does the SCRS model simplify furnace combustion simulation? Efficiency Meets Accuracy in Thermal Modeling

- What is the purpose of using a spiral grain selector? Achieving Single-Crystal Precision in Metal Castings

- How do magnesium impurities influence lithium extraction? Accelerate Production with Heterogeneous Nucleation

- What chemical role does phosphoric acid (H3PO4) play when activating biomass? Master Carbon Material Transformation

- How does temperature control precision affect c-BAs crystal growth? Ensure Lattice Integrity in Two-Week Cycles

- Why is niobium foil wrapped around niobium cavity flanges? Protect Your UHV Seals During Heat Treatment