Magnesium impurities act as a powerful accelerator for lithium extraction rates. Within the reaction vessel, these impurities facilitate a physical process known as heterogeneous nucleation, which drastically speeds up the precipitation of lithium carbonate. By lowering the energy required for crystals to form, magnesium effectively boosts the production efficiency of specific lithium carbonate grades.

Magnesium does not merely exist as a passive contaminant; it actively catalyzes crystallization. By forming nanoscale seeds, magnesium impurities lower the nucleation energy barrier, inducing rapid crystal growth and significantly shortening the time required to produce low-grade lithium carbonate (LCM).

The Mechanism of Acceleration

The presence of magnesium changes the fundamental dynamics of how crystals form within the solution. This occurs through a specific sequence of physical interactions.

Formation of Nanoscale Seeds

During the precipitation reaction, magnesium impurities are not dormant. They preferentially precipitate to form nanoscale hydrated magnesium carbonate ($MgCO_3 \cdot xH_2O$) seeds.

These seeds are small solid particles that appear suspended within the liquid solution.

Heterogeneous Nucleation

These magnesium seeds function as sites for heterogeneous nucleation.

Instead of lithium carbonate having to spontaneously form crystals from the liquid (homogeneous nucleation), it can latch onto these existing magnesium structures. The seeds act as a physical template or scaffold.

Lowering the Energy Barrier

The primary benefit of this "scaffold" effect is thermodynamic. The presence of the magnesium seeds lowers the nucleation energy barrier for lithium carbonate.

Because the system requires less energy to start crystal formation on an existing surface than to create one from scratch, the reaction proceeds much faster.

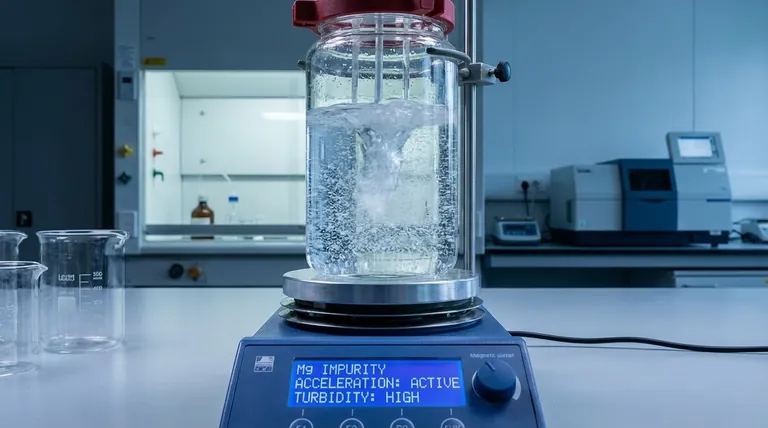

Rapid Turbidity and Growth

The lowered energy barrier leads to immediate physical changes in the vessel. The process induces rapid solution turbidity (cloudiness), indicating that solids are forming quickly.

This accelerates the overall growth of lithium carbonate crystals, directly translating to higher throughput and efficiency in the extraction timeline.

Understanding the Trade-offs

While magnesium impurities enhance speed, it is vital to understand the implications for the final product quality. The primary reference specifies the production of low-grade lithium carbonate (LCM).

Speed vs. Purity

The acceleration mechanism relies on the co-precipitation or inclusion of magnesium. While this acts as a catalyst for speed, the magnesium is inherently part of the nucleation process.

Consequently, this method is optimized for production efficiency of lower-purity grades rather than high-purity battery-grade lithium, where magnesium is typically considered a strict contaminant that must be removed.

Making the Right Choice for Your Goal

Understanding the role of magnesium allows you to optimize your process based on your specific output requirements.

- If your primary focus is Production Speed: Leverage the presence of magnesium to create nucleation seeds, which will lower energy barriers and maximize the throughput of low-grade lithium carbonate.

- If your primary focus is High Purity: Recognize that the acceleration described here comes at the cost of including magnesium in the crystal structure, requiring distinct purification steps if battery-grade purity is the target.

By controlling the nucleation environment, you can turn a common impurity into a strategic tool for efficiency.

Summary Table:

| Feature | Impact of Magnesium Impurities |

|---|---|

| Mechanism | Heterogeneous Nucleation via nanoscale seeds ($MgCO_3 \cdot xH_2O$) |

| Energy Barrier | Significantly lowered, allowing faster crystal formation |

| Extraction Speed | Accelerated; induces rapid solution turbidity and growth |

| Primary Output | Low-grade lithium carbonate (LCM) |

| Process Trade-off | High production throughput vs. presence of impurities |

Optimize Your Lithium Processing Efficiency Today

Are you looking to balance extraction speed with product purity? KINTEK provides the advanced laboratory solutions you need to master complex chemical reactions. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique processing needs.

Whether you are refining low-grade lithium carbonate or engineering high-purity battery materials, our equipment ensures precise thermal control for superior results. Contact KINTEK experts today to discuss your custom furnace solution and take your production efficiency to the next level!

References

- Gogwon Choe, Yong‐Tae Kim. Re-evaluation of battery-grade lithium purity toward sustainable batteries. DOI: 10.1038/s41467-024-44812-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

People Also Ask

- Why is Boron Nitride (BN) powder used as a diluent? Enhance Accuracy in Iron Oxidation Kinetics

- What is the function of a solvothermal reactor during Ir-TiO2 synthesis? Enhance Material Doping and Morphology

- What is the function of a planetary ball mill in magnesium production? Achieve Maximum Reaction Efficiency

- How does calcination temperature affect CuO grain growth? Optimize Nanoporous Film Morphology and Crystallinity

- What is graphite furnace atomic absorption spectroscopy used for? Detecting Trace Elements at Parts-Per-Billion Levels

- What is the significance of industrial drying equipment for metal powders? Master Post-Processing & Quality Control

- What are the main types of sintering furnaces? Find the Perfect Match for Your Materials

- What is the purpose of using a furnace at 500 °C for catalyst support pretreatment? Optimize Purity and Performance