In analytical chemistry, Graphite Furnace Atomic Absorption Spectroscopy (GFAAS) is a highly specialized technique used to measure the concentration of specific elements. Its primary purpose is to quantify elements at extremely low, or "trace," levels, often down to parts per billion (μg/L), using only a very small amount of sample.

The core value of GFAAS lies in its exceptional sensitivity. It is the preferred method when the goal is to detect the smallest possible quantity of an element, especially when the sample itself is scarce or precious.

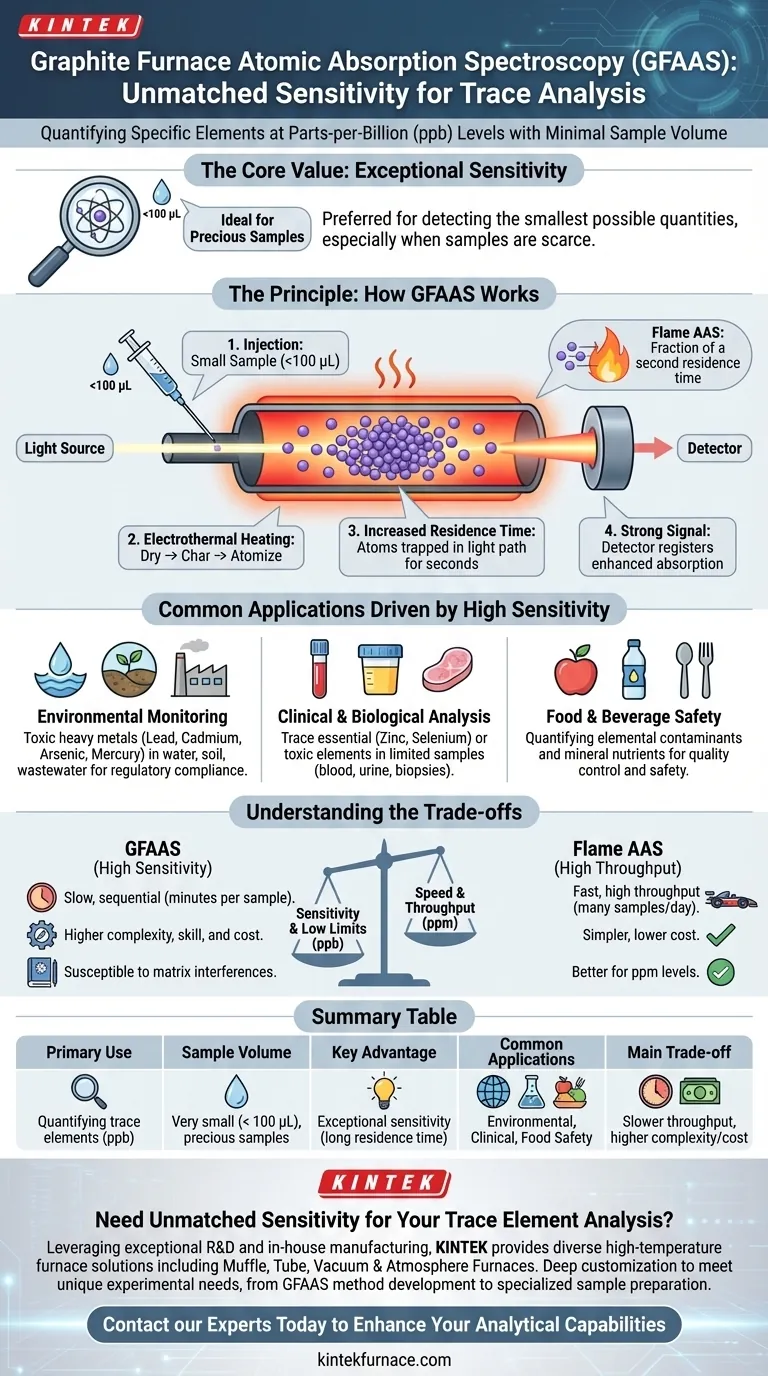

The Principle: Why GFAAS is So Sensitive

The power of GFAAS comes from its unique design, which maximizes the interaction between a light source and the atoms being measured. This design is fundamentally different from other atomic absorption methods.

The Atomizer: A Contained Graphite Tube

Instead of a flame, GFAAS uses a small, hollow graphite tube as its atomizer. The liquid sample, often less than 100 microliters, is injected directly into this tube.

The tube is then heated electrothermally in a programmed sequence to dry, char, and finally atomize the sample, converting the element of interest into a cloud of free atoms.

The Advantage: Increased Residence Time

The key to its sensitivity is that the graphite tube temporarily traps this cloud of atoms. This containment forces the atoms to remain in the path of the instrument's light beam for a significantly longer time—typically a few seconds.

By contrast, in methods like Flame AAS, atoms pass through the light path in a fraction of a second. This extended "residence time" in GFAAS allows the detector to register a much stronger and more distinct signal, even from a tiny number of atoms.

Common Applications Driven by High Sensitivity

The ability to measure minute quantities from small samples makes GFAAS essential in several critical fields.

Environmental Monitoring

GFAAS is a cornerstone for testing for toxic heavy metals like lead, cadmium, arsenic, and mercury in drinking water, soil, and wastewater. Regulators rely on its low detection limits to ensure compliance with safety standards.

Clinical and Biological Analysis

In medicine and toxicology, sample volume is often extremely limited. GFAAS is used to measure trace levels of essential elements (like zinc or selenium) or toxic elements in blood, urine, or tissue biopsies.

Food and Beverage Safety

The technique is used to quantify elemental contaminants in food products that could pose a health risk. It is also applied in quality control to verify the concentration of specific mineral nutrients.

Understanding the Trade-offs

While incredibly powerful, GFAAS is not the universal solution for all elemental analysis. Choosing it involves clear trade-offs.

Throughput and Speed

GFAAS is a slow, sequential technique. Each sample requires a full heating and cooling cycle of the graphite tube, which can take several minutes. This makes it poorly suited for labs needing to process hundreds of samples per day.

Matrix Interferences

Because the method is so sensitive, it is also more susceptible to interference from other components in the sample matrix. Overcoming these chemical and spectral interferences often requires significant method development and optimization.

Cost and Complexity

GFAAS instruments and their consumables (like graphite tubes) are generally more expensive and complex to operate and maintain than their flame-based counterparts. The technique requires a higher level of operator skill.

Making the Right Choice for Your Goal

Selecting the correct analytical technique depends entirely on your specific objective.

- If your primary focus is achieving the lowest possible detection limits (ppb range): GFAAS is the definitive choice, especially when your sample volume is restricted.

- If your primary focus is high sample throughput and speed: Flame AAS is far more efficient for analyzing many samples with concentrations in the parts-per-million (ppm) range.

- If you are analyzing samples with a simple, clean matrix: GFAAS method development will be more straightforward and yield highly reliable results.

Ultimately, selecting GFAAS is a strategic decision to prioritize exceptional sensitivity and low-level detection over analytical speed.

Summary Table:

| Key Feature | Description |

|---|---|

| Primary Use | Quantifying specific elements at trace levels (parts-per-billion). |

| Sample Volume | Very small (often < 100 µL), ideal for precious samples. |

| Key Advantage | Exceptional sensitivity due to increased atom residence time. |

| Common Applications | Environmental monitoring, clinical analysis, food safety. |

| Main Trade-off | Slower throughput compared to Flame AAS; higher complexity and cost. |

Need Unmatched Sensitivity for Your Trace Element Analysis?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet unique experimental requirements—whether you're developing a new GFAAS method or require a specialized furnace for sample preparation.

Contact our experts today to discuss how our precision furnace technology can enhance your analytical capabilities.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- How does graphite contribute to energy efficiency in vacuum furnaces? Achieve Faster, More Uniform Heating

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability