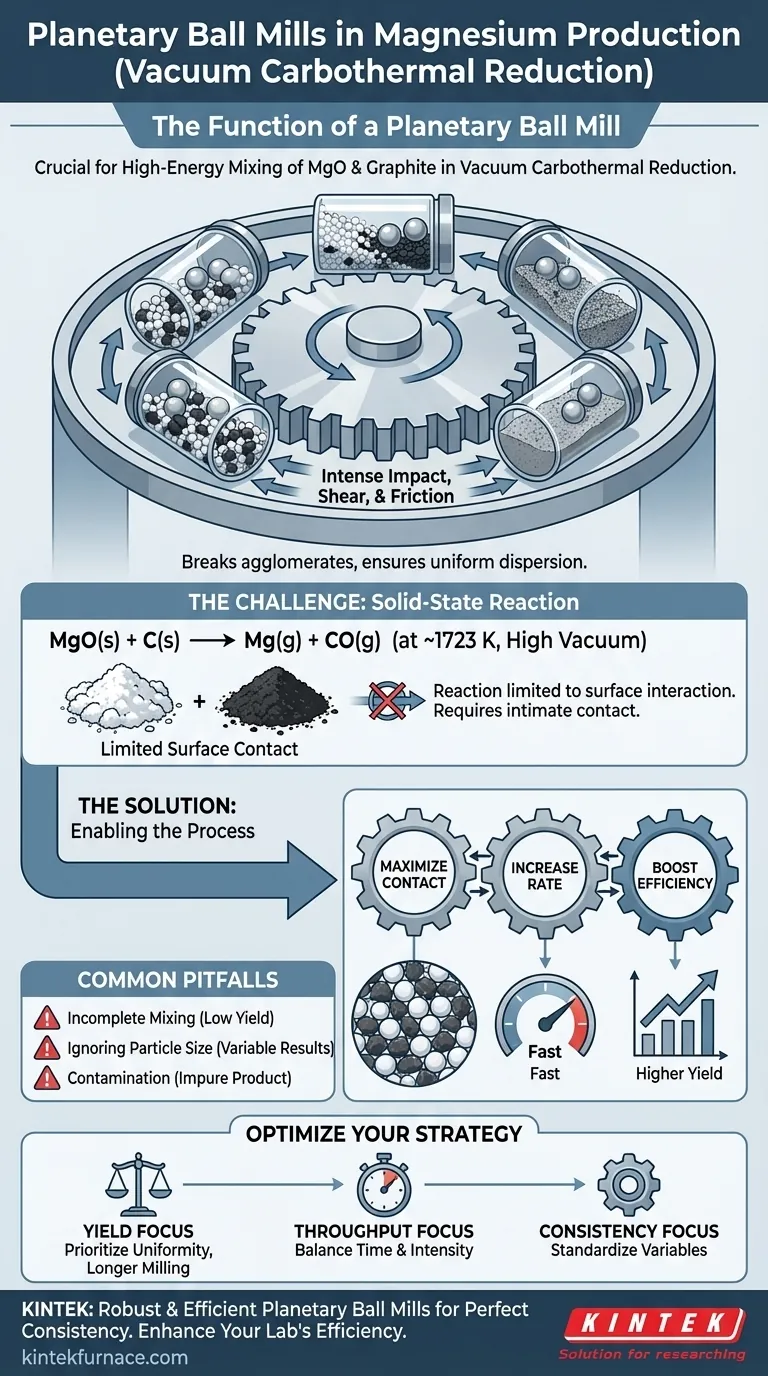

In the vacuum carbothermal reduction of magnesium, the primary function of a planetary ball mill is to perform high-energy mechanical mixing. This process ensures the raw materials, magnesium oxide (MgO) and graphite (C) powders, are dispersed into an exceptionally uniform mixture, which is a critical prerequisite for the subsequent high-temperature reaction.

The planetary ball mill is not merely a mixer; it is an enabler. By ensuring intimate, microscopic contact between solid reactants, it directly governs the rate, efficiency, and ultimate success of the entire magnesium production process.

The Core Principle: Enabling a Solid-State Reaction

Understanding the Process Context

The overall goal is to produce magnesium vapor from magnesium oxide using carbon as a reducing agent (MgO + C → Mg(g) + CO(g)). This reaction is conducted at very high temperatures, such as 1723 K, and under a high vacuum.

The vacuum environment is crucial as it lowers the thermodynamic temperature required for the reaction, saving significant energy. The entire process relies on the physical interaction between solid particles.

The Challenge of Solid-State Reactions

Unlike reactions in a liquid or gas phase where molecules can move freely, reactants in a solid-state reaction can only interact at their surfaces. The reaction's progress is therefore entirely dependent on the available surface area and the proximity of the reactant particles.

Without thorough mixing, large pockets of unreacted magnesium oxide or graphite will remain, severely limiting the process yield.

The Role of High-Energy Milling

A planetary ball mill uses intense mechanical forces—impact, shear, and friction—generated by the grinding balls and the rotating vial. This high-energy action achieves two essential outcomes.

First, it breaks down particle agglomerates, ensuring the individual grains of MgO and graphite are thoroughly dispersed. Second, it guarantees this dispersion is uniform throughout the entire batch, creating the necessary conditions for an efficient reaction.

The Direct Impact of Milling on Process Efficiency

Maximizing Microscopic Contact

The key function of the mill is to create maximum contact points between the magnesium oxide and graphite particles. This intimate, microscopic contact is the single most important factor for the reduction reaction to proceed efficiently.

Influencing Reaction Rate

A more uniform mixture with greater particle contact directly increases the rate of the reduction reaction. When more MgO particles are in direct contact with carbon particles at the target temperature, the conversion to magnesium vapor happens much more quickly.

Boosting Conversion Efficiency

Proper milling leads to higher conversion efficiency, meaning more of the raw magnesium oxide is successfully converted into magnesium. A poorly mixed batch results in wasted raw materials and energy, as the heat and vacuum are applied to material that cannot fully react.

Common Pitfalls in Material Preparation

Incomplete or Insufficient Mixing

The most common failure point is simply not milling the materials for a long enough duration or at a high enough intensity. This results in a non-uniform mixture that directly translates to a low yield.

Ignoring Initial Particle Characteristics

The starting particle size and morphology of the MgO and graphite powders can affect the milling process. Assuming one set of milling parameters will work for all raw material batches is a frequent mistake.

Potential for Contamination

The grinding media (balls and vial) can wear down during high-energy milling, potentially introducing contaminants into the raw material mixture. Choosing the right, durable materials for the mill components is critical to ensure the purity of the final product.

Optimizing Your Raw Material Preparation

The milling step is not just a preliminary task; it is a critical control point for the entire process. Your approach to it should be dictated by your primary production goal.

- If your primary focus is maximizing yield: Prioritize achieving the most uniform and intimate mixture possible, even if it requires longer milling times and careful characterization.

- If your primary focus is increasing throughput: Experiment to find the optimal balance of milling time and intensity that produces an acceptable conversion efficiency in the shortest duration.

- If your primary focus is process consistency: Standardize every variable in the milling process, from the raw material specifications to the milling duration, speed, and ball-to-powder ratio.

Ultimately, mastering this preparation stage is the foundational step toward predictable and efficient magnesium production.

Summary Table:

| Function | Impact on Magnesium Production |

|---|---|

| High-Energy Mechanical Mixing | Creates a uniform, intimate mixture of MgO and graphite powders. |

| Maximizes Microscopic Contact | Directly increases the rate and efficiency of the solid-state reduction reaction. |

| Prevents Incomplete Reactions | Eliminates pockets of unreacted material, boosting final yield and purity. |

Ready to Optimize Your Magnesium Production Process?

The uniformity of your raw material mixture is the foundation of a successful vacuum carbothermal reduction. Backed by expert R&D and manufacturing, KINTEK offers a range of robust and efficient planetary ball mills designed for high-energy mechanical mixing, ensuring your MgO and graphite powders achieve the perfect consistency for maximum conversion efficiency.

Our mills are built for durability to minimize contamination and are customizable to meet your specific production goals, whether you prioritize maximum yield, increased throughput, or process consistency.

Contact our experts today to discuss how KINTEK's solutions can enhance your lab's efficiency and ensure predictable results in your magnesium production.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- How does hot pressing compare to hot isostatic pressing (HIP)? Choose the Right Process for Your Materials

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing

- What is a vacuum press and why is it important in modern manufacturing? Unlock Flawless Bonding and Precision

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What are the key applications of vacuum pressing in composite material processing? Enhance Material Quality and Shape Complexity