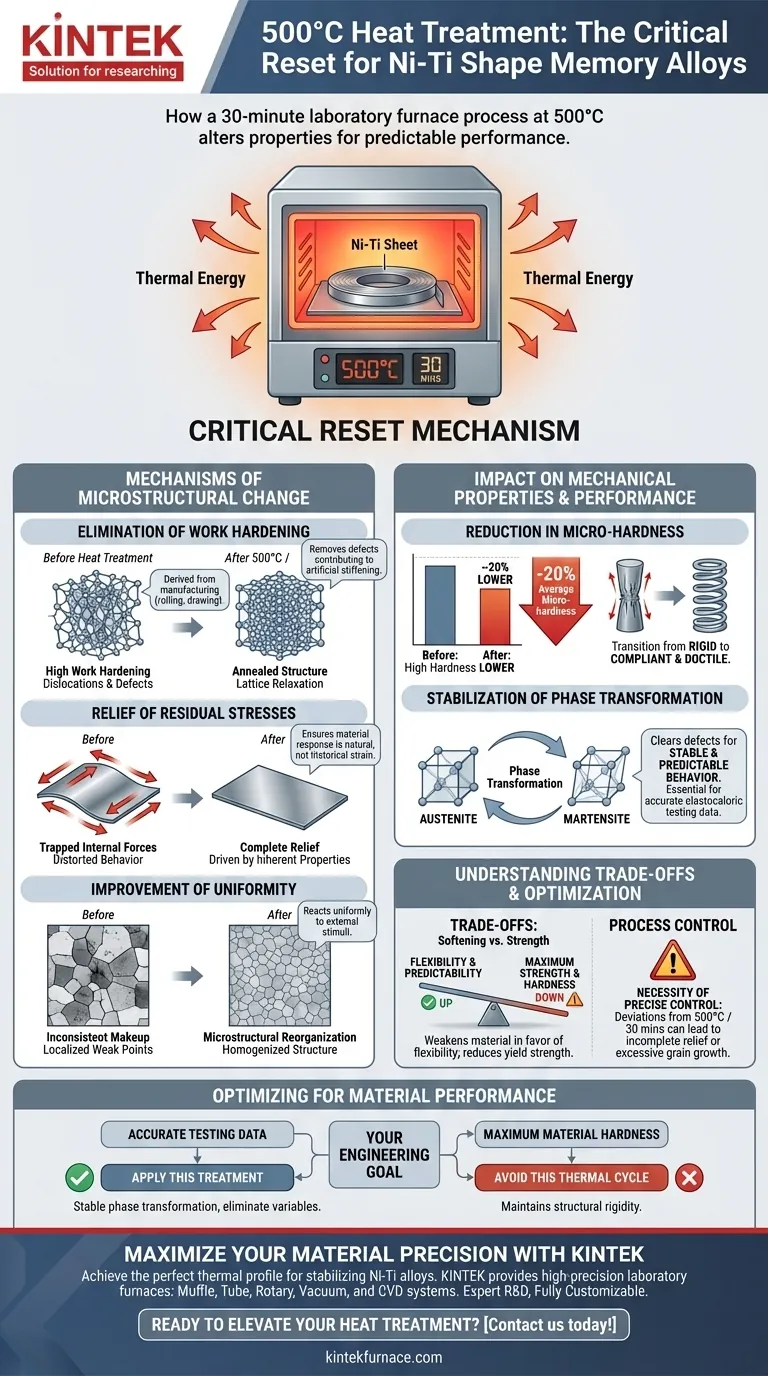

Subjecting Ni-Ti shape memory alloy sheets to a 500°C heat treatment acts as a critical reset mechanism, fundamentally altering the material's internal state by eliminating work hardening and residual stresses. This 30-minute laboratory furnace process induces widespread microstructural reorganization, resulting in a significant reduction in hardness and improved material uniformity.

By removing the internal stresses caused by prior processing, this heat treatment reduces average micro-hardness by approximately 20 percent. This softening effect creates a stable baseline for the material, ensuring predictable phase transformation behavior during elastocaloric testing.

Mechanisms of Microstructural Change

Elimination of Work Hardening

Prior to heat treatment, Ni-Ti alloys often contain significant internal work hardening derived from manufacturing processes like rolling or drawing.

Heating the material to 500°C for 30 minutes effectively anneals the alloy. This thermal energy allows the crystal lattice to relax, removing the dislocations and defects that contribute to artificial stiffening.

Relief of Residual Stresses

Alongside work hardening, processed sheets harbor residual stresses that can distort the material's behavior.

The heat treatment releases these trapped internal forces. This ensures that the material's mechanical response is driven by its inherent properties rather than by historical processing strain.

Improvement of Uniformity

The process triggers a microstructural reorganization across the alloy sheet.

This reorganization homogenizes the material structure. The result is a consistent internal makeup that reacts uniformly to external stimuli, rather than having localized weak points or rigid zones.

Impact on Mechanical Properties

Reduction in Micro-Hardness

The most quantifiable impact of this thermal cycle is a distinct drop in mechanical hardness.

Specifically, the average micro-hardness decreases by approximately 20 percent. This indicates a transition from a rigid, stressed state to a more compliant and ductile condition.

Stabilization of Phase Transformation

For shape memory alloys, the ability to transform between phases (austenite and martensite) is the defining characteristic.

By clearing out defects and stresses, the heat treatment ensures stable and predictable phase transformation behavior. This stability is a prerequisite for accurate data collection during subsequent elastocaloric effect testing.

Understanding the Trade-offs

Softening vs. Strength

While the reduction in hardness is beneficial for shape setting and uniformity, it represents a mechanical trade-off.

The 20 percent reduction in micro-hardness implies a simultaneous reduction in the material's yield strength. If your application requires maximum resistance to indentation or wear, this heat treatment effectively weakens the material in favor of flexibility and predictability.

Necessity of Process Control

The benefits described are specific to the 500°C temperature and 30-minute duration.

Deviating from these parameters could result in incomplete stress relief or excessive grain growth. Precise control of the furnace environment is required to achieve the specific microstructural reorganization described.

Optimizing for Material Performance

To determine if this specific heat treatment aligns with your engineering goals, consider the following:

- If your primary focus is accurate testing data: Apply this treatment to ensure stable phase transformation and eliminate historical processing variables.

- If your primary focus is maximum material hardness: Avoid this specific thermal cycle, as the consequent 20 percent drop in micro-hardness may compromise structural rigidity.

This heat treatment is the definitive step for converting a raw, stressed Ni-Ti sheet into a reliable, uniform component ready for advanced characterization.

Summary Table:

| Property/Mechanism | Change at 500°C (30 mins) | Impact on Performance |

|---|---|---|

| Micro-hardness | ~20% Reduction | Increases ductility and material compliance |

| Internal Stress | Complete Relief | Eliminates distortions from prior processing |

| Microstructure | Reorganization | Enhances material homogeneity and consistency |

| Phase Transformation | Stabilization | Ensures predictable austenite-martensite cycles |

| Work Hardening | Annealing Effect | Removes lattice dislocations and defects |

Maximize Your Material Precision with KINTEK

Achieving the perfect thermal profile is essential for stabilizing Ni-Ti alloys and ensuring predictable phase transformations. KINTEK provides the high-precision laboratory furnaces required to maintain the exact temperature control your R&D demands.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique material science needs. Whether you are performing critical stress relief or complex shape-setting, our high-temp furnaces deliver the uniformity your lab deserves.

Ready to elevate your heat treatment process? Contact us today to find your custom solution!

Visual Guide

References

- Gianmarco Bizzarri, Maria Elisa Tata. Mechanical Response and Elastocaloric Performance of Ni-Ti Shape Memory Alloy Sheets Under Varying Strain Rates. DOI: 10.3390/compounds5020013

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does temperature control play in biomass pyrolysis for biochar? Achieve Optimal Pore Structure & Yield

- Why is a two-step process used for waste bone-derived carbon? Unlock Ultra-High Surface Area & Stability

- What is the purpose of performing high-temperature thermal treatment for BSnO thin films? Boost Device Sensitivity

- Why is an auxiliary gas supply device required for oil sludge pyrolysis? Ensure Stable Thermal Balance

- What is the purpose of pre-baking sapphire substrates? Master Atomic Flatness for Superior Thin Film Growth

- What are the advantages of using a microwave reaction system? Rapid & Uniform Synthesis of Doped Hydroxyapatite

- How can I improve my vacuum pump performance? Optimize Your System for Deeper Vacuum & Faster Pump-Down

- What role does an industrial-grade POCl3 diffusion furnace system play in DOSS? Master Quantitative Phosphorus Control