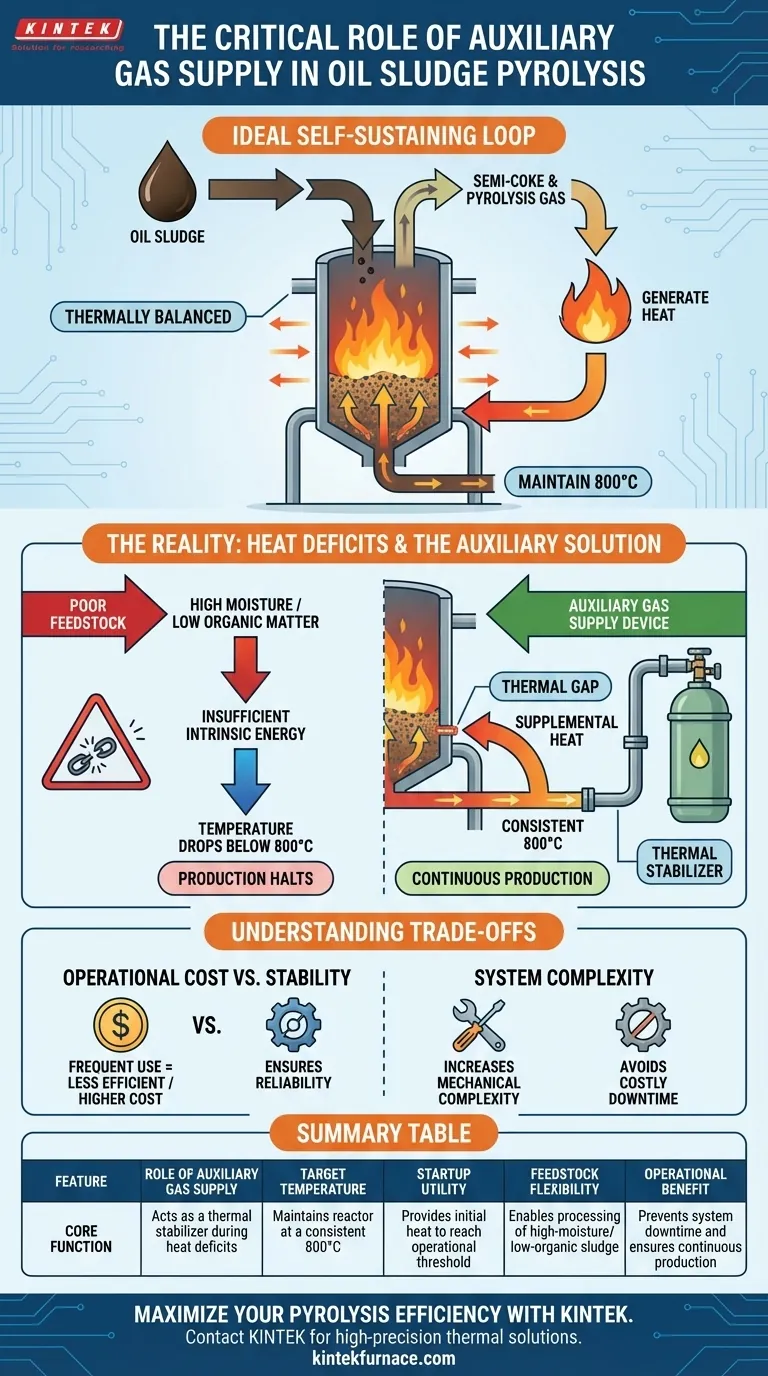

An auxiliary gas supply device acts as a critical thermal stabilizer. It is required to inject supplemental heat into the system when the oil sludge's intrinsic energy content is insufficient to maintain the necessary fluidized bed temperature of 800°C. This ensures the pyrolysis process remains continuous and thermally balanced, particularly during startup or when processing low-quality sludge.

High moisture content or low organic matter in oil sludge can disrupt the system's self-sustaining energy loop. The auxiliary gas supply bridges this thermal gap, preventing temperature drops that would otherwise halt production.

The Challenge of Self-Sustaining Pyrolysis

The Ideal Energy Loop

In an optimal scenario, the pyrolysis process is largely self-sustaining. The semi-coke and pyrolysis gas generated from the sludge possess heating value.

Ideally, these byproducts are combusted to generate the heat required to continue the process.

The Impact of Feedstock Quality

However, the energy loop depends entirely on the quality of the raw material. Oil sludge varies significantly in composition.

Sludge with extremely high moisture content or limited organic matter has a low calorific value. When this type of sludge is processed, it physically cannot release enough heat during combustion to fuel the system alone.

Maintaining Thermal Balance

The 800°C Threshold

The fluidized bed reactor operates effectively at a specific thermal target. To ensure proper decomposition and fluidization, the system must maintain a temperature of 800°C.

If the temperature drops below this threshold due to poor fuel quality, the pyrolysis reaction becomes inefficient or stops completely.

Ensuring Continuous Production

The auxiliary gas supply device prevents these thermal dips. By introducing external fuel, it compensates for the heat deficit caused by wet or inorganic-heavy sludge.

This ensures the system maintains thermal balance, allowing for continuous production regardless of fluctuations in the feedstock quality.

Understanding the Trade-offs

Operational Cost vs. Stability

While the auxiliary device ensures reliability, frequent use indicates a less efficient process. Relying heavily on external gas increases the operational cost of the plant.

System Complexity

Adding an auxiliary supply increases the mechanical complexity of the system. However, this is a necessary trade-off to avoid the much costlier downtime associated with a stalled reactor.

Making the Right Choice for Your Operation

If your primary focus is process stability: Ensure your auxiliary gas supply is fully operational and automated to trigger immediately when reactor temperatures dip below 800°C.

If your primary focus is operational efficiency: Analyze your feedstock prior to processing; reducing moisture content or blending low-organic sludge with higher-energy materials will minimize your reliance on the auxiliary gas device.

The auxiliary gas supply is your insurance policy against inconsistent feedstock, guaranteeing that production continues even when the sludge itself cannot sustain the fire.

Summary Table:

| Feature | Role of Auxiliary Gas Supply |

|---|---|

| Core Function | Acts as a thermal stabilizer during heat deficits |

| Target Temperature | Maintains reactor at a consistent 800°C |

| Startup Utility | Provides initial heat to reach operational threshold |

| Feedstock Flexibility | Enables processing of high-moisture/low-organic sludge |

| Operational Benefit | Prevents system downtime and ensures continuous production |

Maximize Your Pyrolysis Efficiency with KINTEK

Don't let inconsistent feedstock quality or thermal dips halt your production. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. From robust Muffle and Tube furnaces to advanced Vacuum and CVD systems, our lab high-temp equipment is fully customizable to meet your unique processing needs.

Ensure your lab or plant operates with peak reliability. Contact KINTEK today to discover how our high-precision thermal systems can stabilize your operations and enhance your research outcomes.

Visual Guide

References

- Zhengyang Zhang, Changtao Yue. Theoretical Calculation of Heat and Material Balance for Oil Sludge Pyrolysis Process by Solid Heat Carrier Method. DOI: 10.3390/en18020329

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the significance of the vacuum oven drying process in the preparation of MnO@WAC electrode sheets? Expert Guide

- Why must the filling of the working medium into a sodium heat pipe be performed inside a protective glovebox?

- What are the main advantages of crucible furnaces? Unmatched Flexibility for Small-Scale Melting

- What is the purpose of performing a quenching treatment? Optimize Doped Alkali Halide Crystal Spectral Analysis

- What is the role of a dedicated bias power supply in low-pressure plasma nitriding? Master Ion Acceleration Control

- How does an industrial vacuum drying oven affect electrode performance? Optimize Sodium-Ion Battery Stability

- What is the function of a magnetron sputtering system for WS2 thin films? Master Nano-Scale Deposition Control

- Why is HR-TEM used after high-temperature heat treatment? Visualize structural evolution and material integrity.