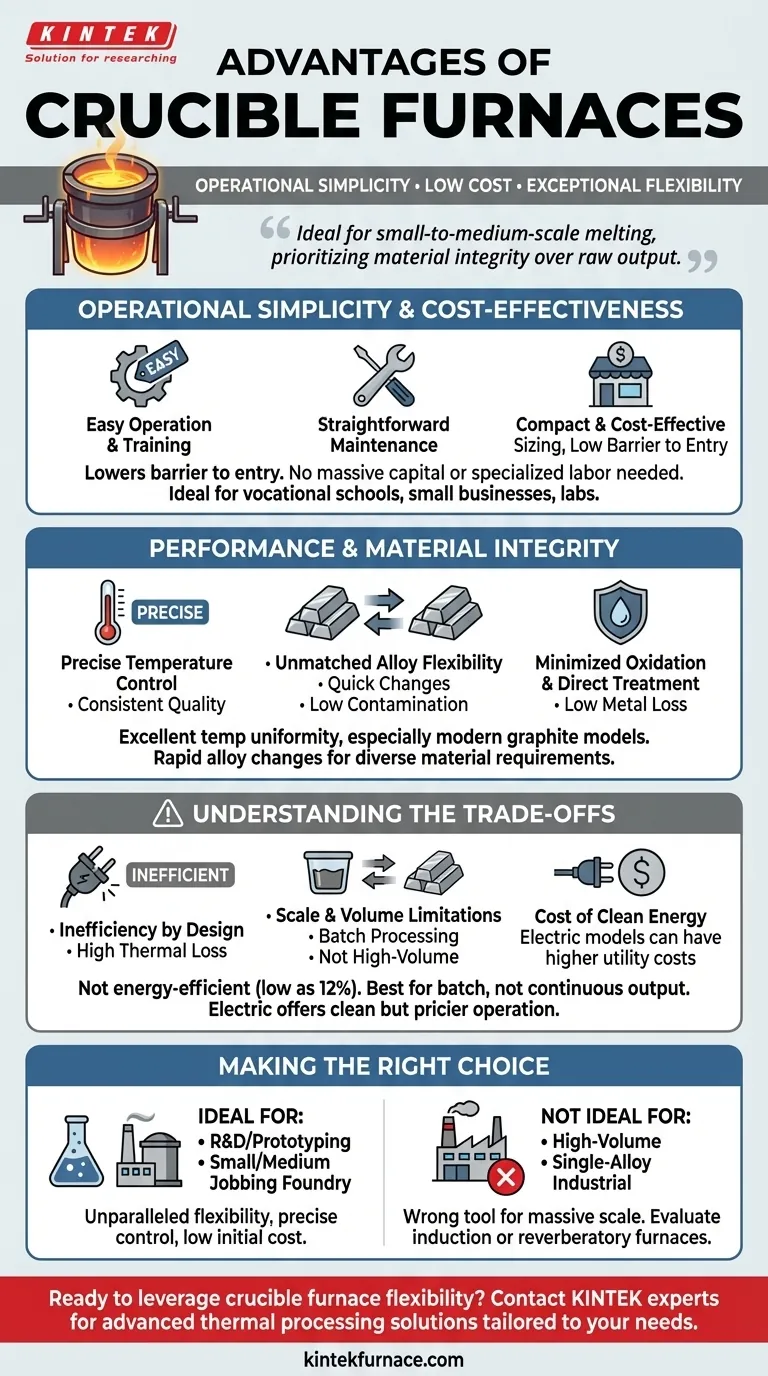

At their core, crucible furnaces are prized for their operational simplicity, low cost, and exceptional flexibility. They provide a cost-effective and easy-to-manage solution for melting small to medium quantities of metal, offering precise temperature control and the ability to quickly switch between different alloys. This makes them a cornerstone for foundries, laboratories, and artisanal workshops.

While not designed for mass production, the primary advantage of a crucible furnace is its unmatched flexibility and control in small-to-medium-scale melting operations, prioritizing material integrity and versatility over raw output and energy efficiency.

Operational Simplicity and Cost-Effectiveness

One of the most significant draws of a crucible furnace is its accessibility. It lowers the barrier to entry for metal melting operations without requiring massive capital investment or highly specialized labor.

Low Barrier to Entry

Crucible furnaces are fundamentally easy to operate. They do not demand extensive, specialized training, allowing teams to become proficient quickly.

This simplicity makes them an ideal choice for vocational schools, small businesses, and laboratories where personnel may have multiple roles and cannot be dedicated solely to furnace operation.

Straightforward Maintenance

The design of these furnaces facilitates straightforward maintenance. This reduces operational downtime, lowers long-term ownership costs, and ensures consistent performance over the furnace's lifespan.

Compact and Cost-Effective Sizing

Crucible furnaces are available in a wide range of sizes, from small tabletop units for jewelry making to larger industrial models. Their relatively compact footprint is a major advantage for facilities with limited space.

For small-to-medium quantity melting, they represent a highly cost-effective solution compared to larger, more complex furnace types.

Performance and Material Integrity

Beyond cost and ease of use, crucible furnaces deliver high-quality performance where it matters most: controlling the melt and preserving the material's properties.

Precise Temperature Control

The ability to achieve and maintain a specific temperature is critical for producing castings with desired metallurgical properties. Crucible furnaces, especially modern graphite models, offer excellent temperature uniformity and precise controllability.

This control ensures consistent melt quality from batch to batch, which is essential for applications with stringent material specifications.

Unmatched Alloy Flexibility

Perhaps the greatest performance advantage is the ability to rapidly change alloys. Since the metal is contained entirely within the crucible, there is minimal cross-contamination between melts.

A foundry can melt a batch of aluminum, switch to a bronze alloy in the next heat, and then to another material with minimal downtime. This is invaluable for jobbing foundries and R&D labs that handle diverse material requirements.

Minimized Oxidation and Direct Treatment

Melting within a self-contained vessel helps limit the metal's exposure to the atmosphere, resulting in low oxidation losses. This preserves the valuable alloying elements and improves the final metal quality.

Furthermore, the crucible itself can be used for direct treatment, such as degassing or adding inoculants, simplifying the overall process.

Understanding the Trade-offs

To make an informed decision, it is critical to weigh the advantages against the inherent limitations of the technology. No furnace is perfect for every application.

Inefficiency by Design

Crucible furnaces are not known for their energy efficiency. The process of heating a crucible, which in turn heats the metal, involves significant thermal loss. Efficiency ratings can be as low as 12% in some models.

This means that while the initial capital cost is low, the per-kilogram energy cost to melt metal can be higher than in other furnace types like induction or reverberatory furnaces.

Scale and Volume Limitations

The very nature of a crucible limits the batch size. These furnaces are not suited for large-scale industrial applications that require melting many tons of metal per hour. Their strength lies in batch processing, not continuous, high-volume output.

The Cost of Clean Energy

While traditional fuel-fired furnaces can produce significant emissions, modern electric crucible furnaces offer a clean, low-emission alternative.

However, this benefit comes at a cost. Electric models can lead to higher utility expenses compared to some gas-fired furnaces, a factor that must be considered for cost-sensitive operations.

Making the Right Choice for Your Goal

The suitability of a crucible furnace depends entirely on your primary operational objective.

- If your primary focus is R&D, prototyping, or multi-alloy artisanal work: The crucible furnace is the ideal choice due to its unparalleled flexibility, precise control, and low initial cost.

- If your primary focus is a small-to-medium jobbing foundry: A crucible furnace provides the necessary versatility to serve diverse customer needs without the massive investment of larger, single-alloy systems.

- If your primary focus is high-volume, single-alloy industrial production: A crucible furnace is likely the wrong tool; you should evaluate more efficient technologies like large induction or reverberatory furnaces.

Ultimately, understanding these advantages and trade-offs empowers you to select the right tool for your specific metal melting task.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Operational Simplicity | Easy to operate and maintain, low training requirement. |

| Cost-Effectiveness | Low initial investment and compact footprint. |

| Alloy Flexibility | Quick change between alloys with minimal cross-contamination. |

| Precise Temperature Control | Excellent for maintaining material integrity and consistent quality. |

| Minimized Oxidation | Low metal loss, preserving valuable alloying elements. |

Ready to leverage the flexibility of a crucible furnace in your lab or foundry?

At KINTEK, we understand that your success depends on having the right tools for precise, small-to-medium-scale melting. Leveraging exceptional R&D and in-house manufacturing, we provide advanced thermal processing solutions tailored to your unique needs. Whether you require a standard model or a deeply customized system, our expertise ensures optimal performance for your specific alloys and processes.

Contact our experts today to discuss how our solutions can enhance your operational flexibility and material quality.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a high-pressure digestion tank essential for ZnO/rGO hydrothermal synthesis? Achieve superior interfacial coupling

- How does the use of carbon dioxide and a flow meter impact the physical activation of biochar? Master Pore Development

- Why is the transformation of ZnS to ZnO critical in microwave-assisted zinc recovery? Unlock 92.5% Extraction Yields

- What is the role of a vacuum drying oven in processing MOF precursors? Preserve Integrity for Co-HCC Synthesis

- Why is an aging station required for Ni-doped LaFeO3 gas sensors? Ensure Stability and Precision

- What are the advantages of using an industrial-grade rapid heating furnace? Maximize Glass-Ceramic Debinding Efficiency

- What are the primary process objectives of using an infrared belt furnace? Optimize TOPCon Solar Cell Metallization

- What role does fluorination process equipment play in the pretreatment of LiF-BeF2 salts? Ensure High-Purity Substrates