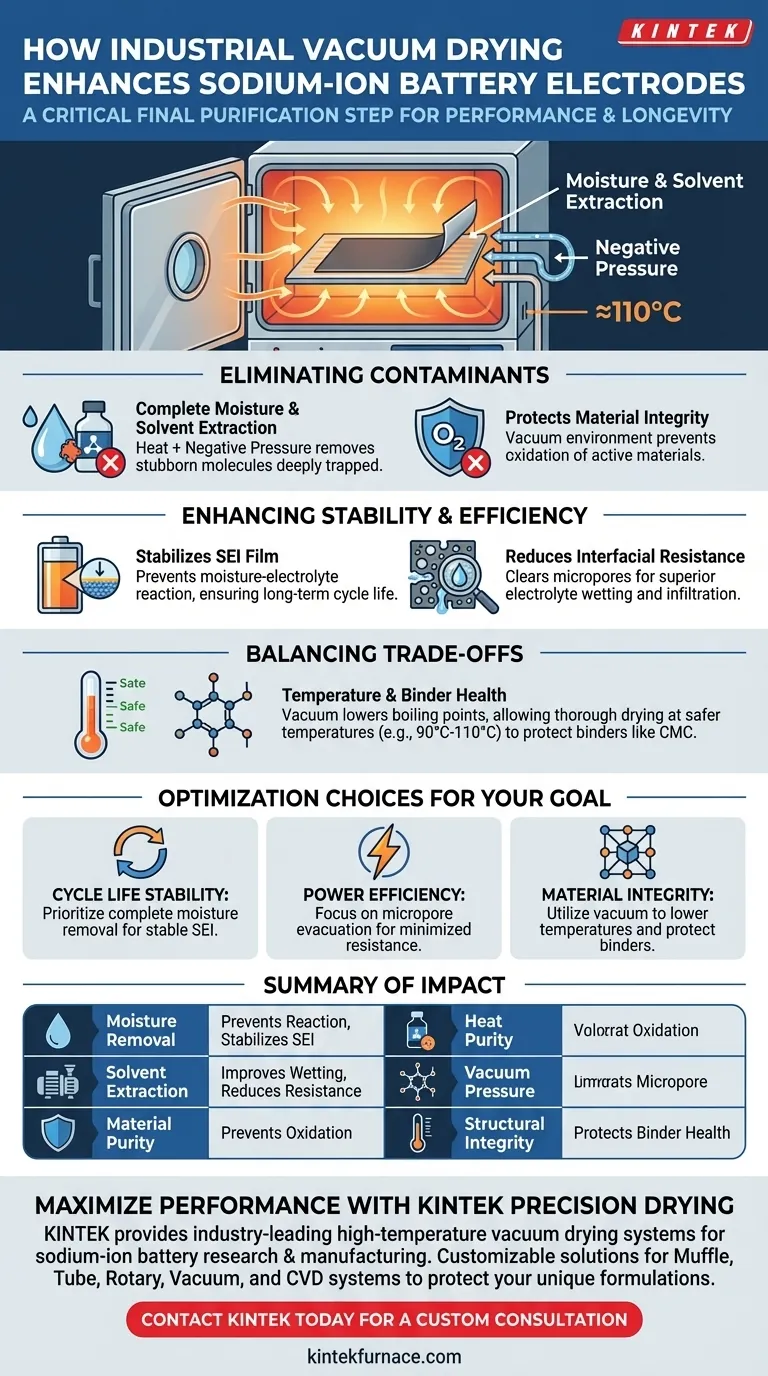

An industrial vacuum drying oven serves as the critical final purification step for electrode sheets prior to sodium-ion battery assembly. By subjecting coated sheets to temperatures around 110 °C under negative pressure, the process completely eliminates residual moisture and solvent molecules trapped within the internal electrode structure.

The removal of microscopic contaminants is essential for preventing moisture from reacting with sodium salt electrolytes, thereby ensuring the formation of a stable solid electrolyte interface (SEI) film.

Eliminating Chemical Contaminants

Complete Moisture and Solvent Extraction

The primary function of the oven is to treat electrode sheets at elevated temperatures (typically 110 °C) overnight.

However, heat alone is insufficient; negative pressure is utilized to forcibly extract stubborn solvent molecules and moisture from the deep internal structure of the electrode.

Protecting Material Integrity

Operating in a vacuum environment allows for effective drying without exposing the materials to oxygen.

This prevents the oxidation of active materials that often occurs during conventional heating, preserving the chemical purity of the electrode surface.

Enhancing Battery Stability and Efficiency

Stabilizing the SEI Film

Thorough drying is the primary defense against electrolyte decomposition.

If moisture remains, it reacts with sodium salt electrolytes, leading to detrimental side reactions.

Removing this moisture ensures the formation of a stable solid electrolyte interface (SEI), which is fundamental to the battery's long-term cycle life.

Reducing Interfacial Resistance

The vacuum process clears residual solvents from the micropores of the electrode materials.

This ensures the active surfaces are fully accessible, allowing electrolytes (such as PVA-KOH gel) to effectively wet and infiltrate the electrode arrays.

Superior infiltration significantly reduces interfacial resistance, improving the overall efficiency of the battery.

Understanding the Trade-offs

Balancing Temperature and Binder Health

While high heat speeds up drying, excessive temperatures can degrade critical components like the binder (CMC).

The vacuum environment mitigates this risk by effectively lowering the boiling point of solvents.

This allows for deep, thorough drying at safer temperatures (e.g., 90 °C - 110 °C), ensuring the binder structure remains intact while contaminants are removed.

Making the Right Choice for Your Goal

To optimize your sodium-ion battery assembly, consider how the drying parameters align with your specific performance targets:

- If your primary focus is Cycle Life Stability: Ensure the process prioritizes the complete removal of moisture to prevent electrolyte reaction and stabilize the SEI film.

- If your primary focus is Power Efficiency: Focus on the thorough evacuation of micropores to maximize electrolyte wetting and minimize interfacial resistance.

- If your primary focus is Material Structural Integrity: Utilize the vacuum's ability to lower boiling points to dry at temperatures that protect your specific binder formulation.

Precise control over vacuum drying turns a simple heating step into a critical safeguard for battery chemistry and longevity.

Summary Table:

| Impact Factor | Drying Mechanism | Benefit to Battery Performance |

|---|---|---|

| Moisture Removal | Vacuum extraction at ~110°C | Prevents electrolyte reaction; stabilizes SEI film |

| Solvent Extraction | Negative pressure in micropores | Improves electrolyte wetting; reduces interfacial resistance |

| Material Purity | Oxygen-free environment | Prevents oxidation of active materials |

| Structural Integrity | Lowered boiling points | Protects binder (CMC) health from thermal degradation |

Maximize Your Battery Performance with KINTEK Precision Drying

Don't let microscopic moisture compromise your battery’s cycle life. KINTEK provides industry-leading high-temperature vacuum drying systems specifically designed to meet the rigorous demands of sodium-ion battery research and manufacturing.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to protect your unique binder formulations and active materials. Ensure a stable SEI film and superior power efficiency with our targeted thermal solutions.

Ready to optimize your assembly process? Contact KINTEK today for a custom consultation!

Visual Guide

References

- Rajib Samanta, Sudip Barman. Correlating the Sodium Storage Mechanism and Enhancing the Initial Coulombic Efficiency of Biomass‐Derived Hard Carbon in Sodium‐Ion Batteries. DOI: 10.1002/batt.202500295

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why use automatic temperature compensation for Sb-Te melts? Ensure Data Accuracy with Precise Thermal Control

- What is the function of a forced drying oven in SiOC coating conversion? Ensure Flawless Solvent Removal

- Why is a vacuum drying oven necessary for activated carbon? Ensure Accurate BET and Pore Size Analysis

- What role does fluorination process equipment play in the pretreatment of LiF-BeF2 salts? Ensure High-Purity Substrates

- What is the purpose of using a preheated stainless steel plate when processing molten glass? Avoid Thermal Stress.

- What is the significance of the dual-crucible arrangement in NCMCS sulfidation? Enhance Purity and Control

- What advantages does a vacuum drying oven offer for Fe-N-BC catalysts? Protect Integrity and Improve Uniformity

- Why is a laboratory tablet press used to briquette powder before vacuum carbothermic reduction? Ensure Efficient & Stable Magnesium Production