The primary function of a forced drying oven in SiOC coating conversion is to facilitate the controlled, steady evaporation of solvents. By maintaining a constant temperature (typically 80 °C) with active hot air circulation, the oven removes volatile mixtures like butanol and xylene without inducing thermal shock. This creates a stable precursor state essential for successful ceramicization.

Core Takeaway This pre-drying stage is not merely about removing liquid; it is a structural stabilization process. It prevents the formation of surface "skin" that traps vapors, thereby eliminating defects like bubbles and pinholes to ensure a dense, uniform coating prior to high-temperature treatment.

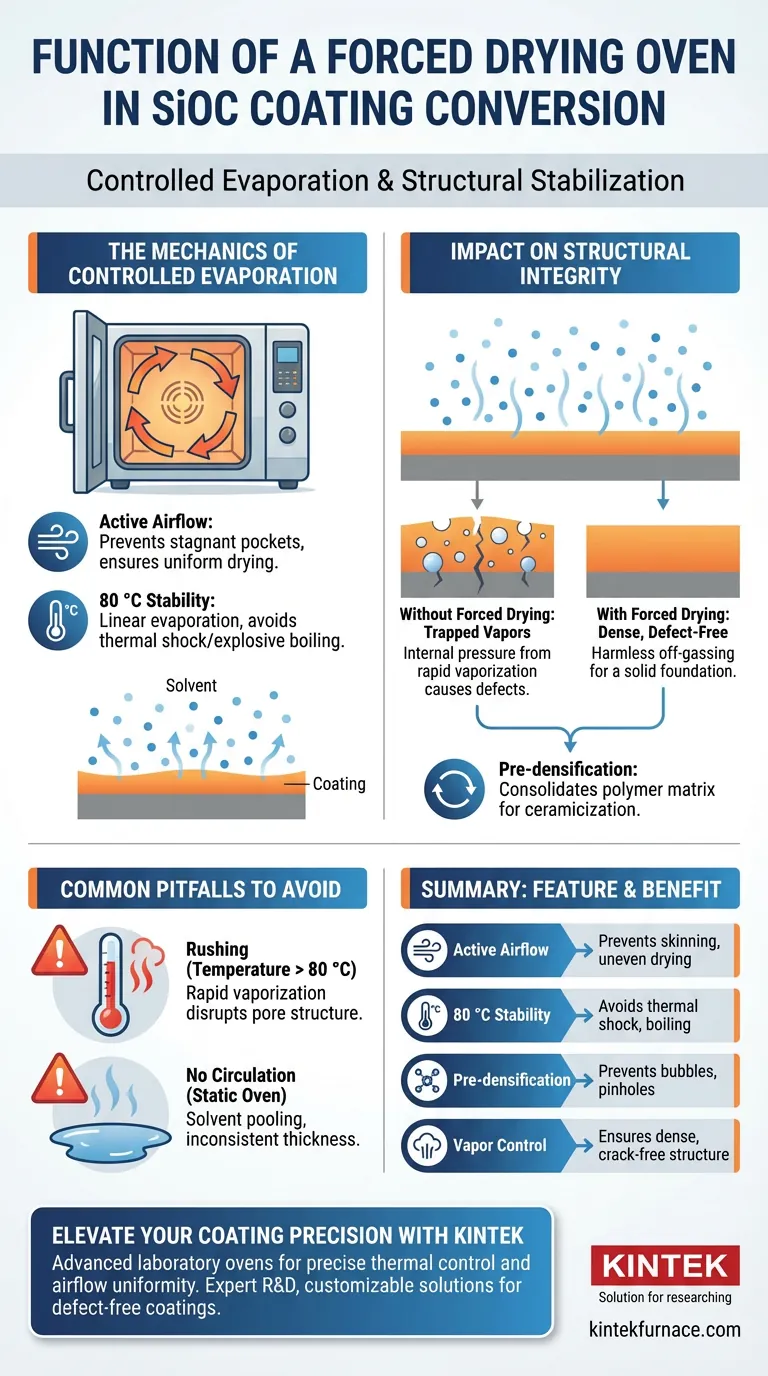

The Mechanics of Controlled Evaporation

To understand the necessity of this equipment, one must look at how solvents behave within the coating matrix during the transition from liquid to solid.

Regulating Temperature and Airflow

The "forced" aspect of the oven creates a dynamic environment where hot air is continuously circulated.

This prevents the formation of stagnant air pockets or temperature gradients that could lead to uneven drying.

By holding the environment at a moderate 80 °C, the system ensures that solvents evaporate at a linear rate, rather than boiling off explosively.

Preventing Surface Skinning

A common failure mode in coating conversion is "skinning," where the surface dries and hardens while the interior remains liquid.

Forced air circulation ensures that the solvent concentration gradient is managed effectively, keeping the surface porous enough for internal solvents to escape.

This prevents the outer layer from sealing prematurely, which is critical for maintaining the geometric integrity of the coating.

Impact on Structural Integrity

The quality of the final ceramic material is largely dictated by how effectively the precursor coating is consolidated during this low-temperature phase.

Eliminating Trapped Vapors

If solvents such as butanol and xylene are not removed gently, they remain trapped within the polymer network.

When the material is later subjected to higher temperatures, these trapped pockets vaporize rapidly, creating internal pressure.

The forced drying step mitigates this by allowing these volatiles to off-gas harmlessly, preventing the formation of bubbles or burst pinholes.

Preparing for High-Temperature Ceramicization

The ultimate goal of the process is to prepare the SiOC coating for heat treatment above 450 °C.

The drying oven establishes a dense, defect-free structural foundation.

Without this pre-densification, the rigorous thermal expansion and contraction of the ceramicization phase would likely cause the coating to crack or delaminate.

Common Pitfalls to Avoid

While the concept of drying is simple, the execution requires precision. Understanding the trade-offs in this stage is vital for process control.

The Risk of Rushing

Attempting to accelerate this stage by increasing the temperature significantly above 80 °C is a common error.

Higher temperatures may remove solvent faster, but they increase the risk of rapid vaporization, which disrupts the coating's pore structure.

The Necessity of Circulation

Relying on a static oven (without forced air) often leads to "solvent pooling" in the atmosphere around the sample.

This creates high local humidity of solvent vapors, slowing the drying process unpredictably and leading to inconsistent coating thickness.

Optimizing Your Conversion Process

The specific parameters you choose should align with the critical quality metrics of your final application.

- If your primary focus is Surface Aesthetics: Prioritize the consistency of airflow to prevent skinning; uneven drying is the leading cause of visible surface irregularities.

- If your primary focus is Structural Density: Ensure the drying duration is sufficient to remove all solvent traces before moving to the >450 °C stage to prevent internal void formation.

The forced drying oven acts as the gatekeeper of quality, ensuring the chemical precursor is physically stable enough to endure the thermal stress of becoming a ceramic.

Summary Table:

| Feature | Function in SiOC Conversion | Benefit to Coating Quality |

|---|---|---|

| Active Airflow | Eliminates stagnant solvent pockets | Prevents surface skinning and uneven drying |

| 80 °C Stability | Linear evaporation of butanol/xylene | Avoids thermal shock and explosive boiling |

| Pre-densification | Consolidates the polymer matrix | Prevents bubbles and pinholes in ceramic phase |

| Vapor Control | Facilitates harmless off-gassing | Ensures a dense, crack-free structural foundation |

Elevate Your Coating Precision with KINTEK

Don't let volatile solvents compromise your material integrity. KINTEK’s advanced laboratory ovens and high-temperature systems are engineered to provide the precise thermal control and airflow uniformity required for critical SiOC conversion and ceramicization stages.

Why partner with KINTEK?

- Expert R&D & Manufacturing: Our systems are built for consistency and long-term durability.

- Customizable Solutions: From forced air drying ovens to Vacuum, CVD, and Tube furnaces, we tailor equipment to your unique lab specifications.

- Proven Results: We help researchers and manufacturers achieve defect-free, high-density coatings through superior heat treatment technology.

Ready to optimize your thermal processes? Contact KINTEK today for a consultation and let our experts help you select the perfect furnace for your needs.

Visual Guide

References

- Ravi Arukula, Xiaoning Qi. Corrosion resistant coating fabrication through synergies between SiOC conversion and iron oxidation at high temperatures. DOI: 10.1038/s41529-025-00584-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How does a laboratory oven contribute to the hydrothermal treatment of graphene aerogels? Master High-Strength Synthesis

- What problem does a fluidized bed address in ceramic molds? Ensure Uniform Shells for High-Temp Casting

- How does a vacuum drying oven contribute to the preparation of Na3(VO1-x)2(PO4)2F1+2x? Ensure High-Purity Synthesis

- How do high-temp furnaces influence LTO sintering? Optimize Lithium Titanate Performance via Precision Control

- Why is an environmental laboratory chamber equipped with an optical window required for synthesizing Hafnium Carbide?

- Why is a high-pressure autoclave essential for nanomaterials? Unlock Superior Crystallinity and Quantum Yield

- How is the problem of surface oxidation and decarburization addressed in conventional heat treatment? Learn the Machining Allowance Method

- What is the importance of a laboratory oven's programmed heating for epoxy-polyimide curing? Essential Thermal Control