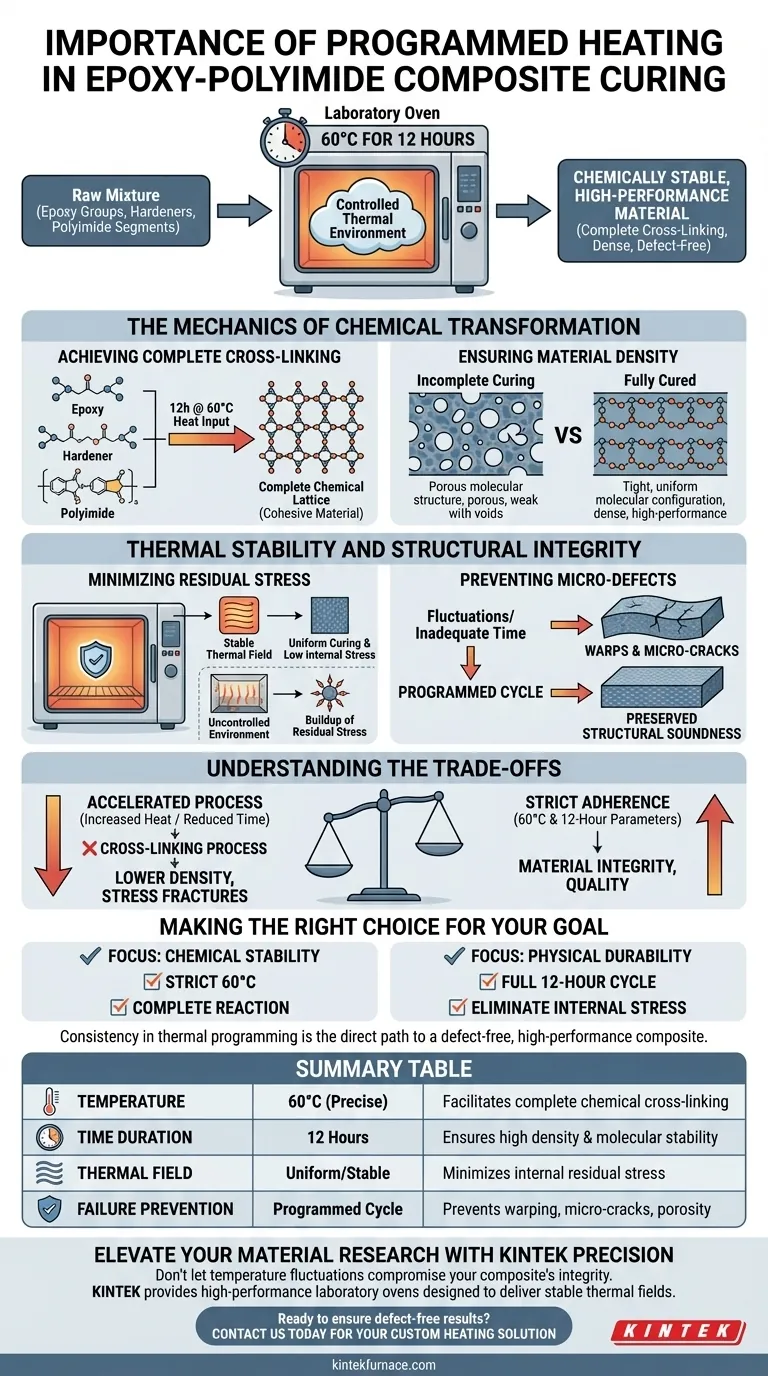

Precise thermal control is the single most critical factor in defining the mechanical properties of epoxy-polyimide composites. By strictly maintaining a programmed temperature of 60°C for a duration of 12 hours, a laboratory oven ensures the complete cross-linking of chemical bonds. This controlled environment transforms the raw mixture into a chemically stable, high-performance material.

The oven does more than simply dry or harden the material; it generates a stable thermal field that is essential for minimizing internal residual stress. This consistency is the only way to guarantee a dense final product free from structural defects.

The Mechanics of Chemical Transformation

Achieving Complete Cross-Linking

The fundamental purpose of the programmed heating cycle is to facilitate a specific chemical reaction. The heat energy drives the interaction between epoxy groups, hardeners, and polyimide segments.

Without this sustained thermal input, the chemical lattice remains incomplete. The 12-hour duration at 60°C ensures that these bonds form fully, resulting in a cohesive material structure.

Ensuring Material Density

A fully cured composite is characterized by its density. The programmed heating allows the molecular chains to settle into a tight configuration.

This density is directly responsible for the "high-performance" designation of the final product. Incomplete curing would result in a porous or weaker material.

Thermal Stability and Structural Integrity

Minimizing Residual Stress

One of the hidden dangers in composite manufacturing is internal tension. A laboratory oven combats this by maintaining a stable thermal field.

When heat is applied evenly and consistently, the material cures uniformly throughout its volume. This uniformity prevents the buildup of internal residual stress that often occurs in uncontrolled environments.

Preventing Micro-Defects

Fluctuations in temperature or inadequate curing times are the primary causes of physical deformities. The programmed cycle is the defense against these failures.

By controlling the thermal environment, the process specifically prevents the formation of warps and micro-cracks. This ensures the physical dimensions and structural soundness of the composite are preserved.

Understanding the Trade-offs

The Risk of Deviation

Strict adherence to the 60°C and 12-hour parameters is not a suggestion; it is a requirement for quality. There is a rigid trade-off between time savings and material integrity.

Attempting to accelerate the process by increasing heat or reducing time will disrupt the cross-linking process. This almost invariably leads to a product with lower density and higher susceptibility to stress fractures.

Making the Right Choice for Your Goal

To maximize the quality of your epoxy-polyimide composites, you must align your processing parameters with the material's chemical requirements.

- If your primary focus is Chemical Stability: Ensure the oven maintains a strict 60°C to guarantee the complete reaction between epoxy groups, hardeners, and polyimide segments.

- If your primary focus is Physical Durability: strictly adhere to the full 12-hour cycle to eliminate internal residual stress and prevent warping.

Consistency in your thermal programming is the direct path to a defect-free, high-performance composite.

Summary Table:

| Curing Parameter | Requirement | Impact on Composite Property |

|---|---|---|

| Temperature | 60°C (Precise) | Facilitates complete chemical cross-linking |

| Time Duration | 12 Hours | Ensures high density and molecular stability |

| Thermal Field | Uniform/Stable | Minimizes internal residual stress |

| Failure Prevention | Programmed Cycle | Prevents warping, micro-cracks, and porosity |

Elevate Your Material Research with KINTEK Precision

Don't let temperature fluctuations compromise your composite's integrity. KINTEK provides high-performance laboratory ovens designed to deliver the stable thermal fields required for complex curing cycles. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your specific lab requirements.

Ready to ensure defect-free results? Contact us today to find your custom heating solution.

Visual Guide

References

- Teguh Endah Saraswati, Wijang Wisnu Raharjo. Enhanced Performance of Epoxy Resin-Polyimide Hybrid Composites with Aminated Carbon Nanofibers Filler. DOI: 10.26554/sti.2025.10.1.152-164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What are the advantages of using a vacuum freeze dryer? Achieve Superior Morphology Control for Silica Nanoparticles

- Why is pre-sintering of Ga2O3 raw material powder required? Unlock Beta-Phase Stability for High-Performance Thin Films

- Why is a drying oven preferred for the post-treatment cleaning of activated carbon? Protect Your Material's Structure

- What advantages does AlMe2iPrO (DMAI) offer over Trimethylaluminum (TMA)? Achieve Superior Area Selectivity

- What role does a laboratory oven play in W-doped TiO2? Ensure Precursor Stability for High-Purity Nanopowders

- What is the significance of preheating UHPC molds? Ensure Safety & Longevity with High-Temp Furnaces

- What role does an ultrafast Joule heating device play in the synthesis of heterostructure nanocatalysts?

- Why must calcination equipment be used to pre-treat ZSM-5 zeolite? Ensure Accurate VOC Adsorption Testing