Precise temperature control is the primary reason a drying oven is preferred over standard heating methods for the post-treatment of activated carbon. A drying oven, particularly one capable of maintaining a stable 105°C for extended periods (such as 24 hours), ensures the removal of moisture trapped deep within complex micropores without thermally shocking or damaging the carbon’s delicate pore structure.

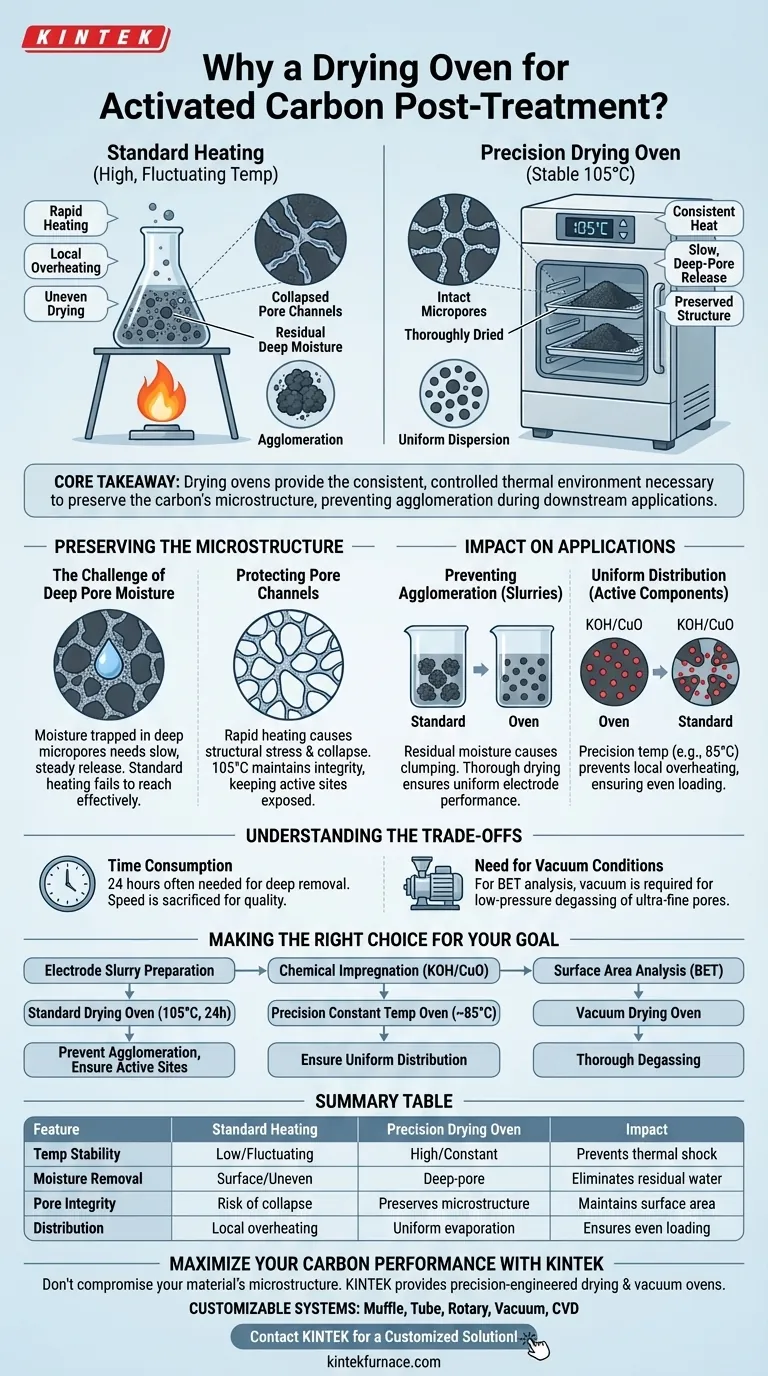

Core Takeaway: Standard heating methods often cause local overheating or uneven drying, which can collapse pore channels or leave residual moisture. A drying oven provides the consistent, controlled thermal environment necessary to preserve the carbon's microstructure, preventing agglomeration during downstream applications like electrode manufacturing.

Preserving the Microstructure

The Challenge of Deep Pore Moisture

After acid washing and neutralization, moisture is not just on the surface of the carbon; it is trapped within deep micropores.

Standard heating methods often lack the consistency to reach these depths effectively without overheating the exterior.

A drying oven allows for a slow, steady release of these trapped water molecules, ensuring the material is thoroughly dried from the inside out.

Protecting Pore Channels

Activated carbon relies on its complex network of pore channels for its performance.

Rapid or uneven heating can cause structural stress, leading to the collapse of these channels.

By maintaining a strict temperature (e.g., 105°C), a drying oven preserves the integrity of these channels, ensuring that active sites remain fully exposed for future chemical reactions.

Impact on Downstream Applications

Preventing Agglomeration in Slurries

The presence of residual moisture is detrimental when preparing electrode slurries.

If water remains in the micropores, the carbon material is prone to agglomeration (clumping) during the mixing process.

Thorough drying in an oven ensures the carbon particles remain discrete and disperse fluidly, which is critical for the uniform performance of the final electrode.

Uniform Distribution of Active Components

When activated carbon is loaded with agents like potassium hydroxide (KOH) or copper oxide (CuO), temperature stability is even more critical.

Drying ovens, often set to lower precision temperatures like 85°C for these applications, ensure solvents evaporate smoothly.

This prevents local overheating, which can cause active components to distribute unevenly or block pores entirely, rendering the carbon less effective.

Understanding the Trade-offs

Time Consumption

The primary drawback of using a precision drying oven is the time investment.

Processes often require 24 hours of continuous heating to guarantee deep moisture removal.

Standard, higher-heat methods are faster but sacrifice the structural quality of the carbon.

The Need for Vacuum Conditions

For specific analytical goals, a standard atmospheric drying oven may not be enough.

To remove ultra-fine adsorbed molecules for BET surface area analysis, a vacuum drying oven is required to lower the pressure.

Standard ovens cannot provide the low-pressure degassing environment needed to prevent data deviations in sensitive porosity tests.

Making the Right Choice for Your Goal

To maximize the performance of your activated carbon, align your drying method with your specific objective:

- If your primary focus is Electrode Slurry Preparation: Use a standard drying oven at 105°C for 24 hours to prevent agglomeration and ensure active site exposure.

- If your primary focus is Chemical Impregnation (e.g., KOH/CuO): Use a precision constant temperature oven at roughly 85°C to ensure uniform distribution of active components.

- If your primary focus is Surface Area Analysis (BET): Use a vacuum drying oven to thoroughly degas the material and remove residual solvents from ultra-fine micropores.

Prioritize the integrity of the pore structure over speed to ensure high-performance results.

Summary Table:

| Feature | Standard Heating | Precision Drying Oven | Impact on Activated Carbon |

|---|---|---|---|

| Temperature Stability | Low/Fluctuating | High (Constant 105°C/85°C) | Prevents thermal shock and pore collapse. |

| Moisture Removal | Surface-level/Uneven | Deep-pore penetrating | Eliminates residual water that causes clumping. |

| Pore Integrity | Risk of channel collapse | Preserves microstructure | Maintains high surface area for active sites. |

| Distribution | Potential local overheating | Uniform solvent evaporation | Ensures even loading of agents like KOH or CuO. |

Maximize Your Carbon Performance with KINTEK

Don't compromise your material's microstructure with inconsistent heating. KINTEK provides precision-engineered drying and vacuum ovens designed to protect delicate pore networks and ensure uniform results. Backed by expert R&D and manufacturing, we offer a full range of customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for high-performance lab applications.

Ready to elevate your electrode manufacturing or chemical research? Contact KINTEK today for a customized solution!

Visual Guide

References

- Ria Yolanda Arundina, Bambang Subiyanto. Preparation of nitrogen-doped activated carbon from palm oil empty fruit bunches for electrodes in electric double-layer capacitance-type supercapacitors: effect of pyrolysis temperature. DOI: 10.1093/ce/zkae100

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a Teflon-lined autoclave in hydrothermal acid treatment? Enhance Catalyst Synthesis Efficiency

- What are the benefits of adding calcium oxide in sludge thermal treatment? Boost Efficiency & Reduce Emissions

- Why is a vacuum oven required during the preparation of Al-CNTs/h-BN composites? Prevent Defects & Ensure Purity

- Why is a constant temperature drying oven used at 120°C for 16 hours for NiCuCe catalysts? Optimize Site Dispersion

- How does precise heating rate control affect nitrogen-doped carbon synthesis? Master Thermal Ramp for Quality Materials

- Why is a forced air circulation oven required for Al-Cu-Mn alloy aging? Achieve Peak Hardness with Uniform Heat

- Why is thermal treatment of Mn1/CeO2 catalysts necessary? Unlock Peak Activation and Purity

- What is the significance of using high-temperature heating equipment to reach 1250°C for alloys? Stress Test Excellence