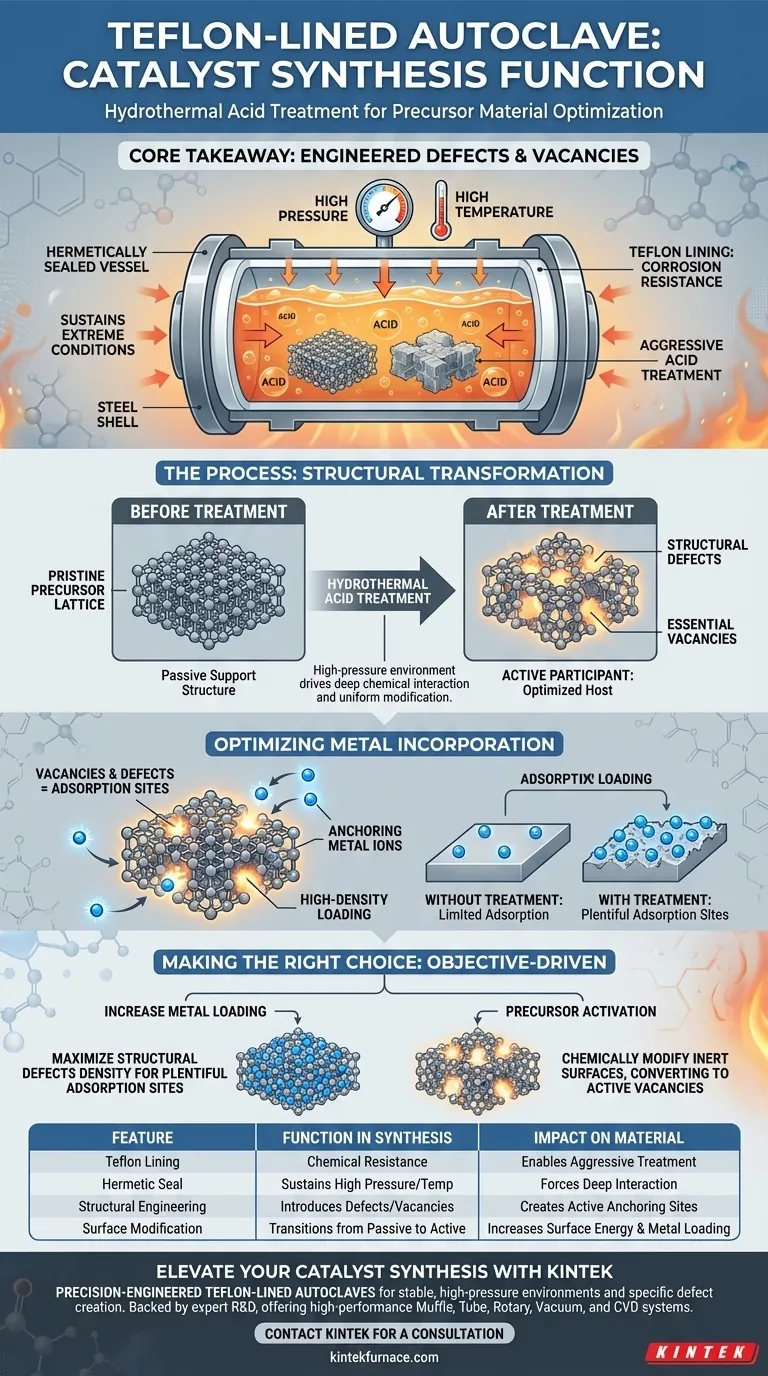

A Teflon-lined autoclave functions as a specialized, sealed reaction vessel designed to withstand the rigors of hydrothermal acid treatment during catalyst preparation. By maintaining high temperatures and pressures within a corrosion-resistant chamber, it drives the chemical modification of precursor materials to enhance their reactivity.

Core Takeaway The primary role of the autoclave is to create a high-pressure environment that facilitates aggressive acid treatment. This process engineers specific structural defects and vacancies into the precursor, transforming it into an optimized host for capturing metal ions.

The Mechanics of Hydrothermal Treatment

Sustaining Extreme Conditions

The autoclave provides a hermetically sealed environment. This isolation allows the internal system to reach and sustain temperatures and pressures far exceeding those possible in open vessels.

Facilitating Acid Interaction

The Teflon lining is critical for this specific application. It allows for the use of corrosive acidic solutions without damaging the steel reactor shell.

Under these intensified conditions, the acid treatment can penetrate the precursor material more effectively. This ensures a uniform and deep chemical interaction throughout the substance.

Engineering the Precursor Structure

Introducing Structural Defects

The high-pressure acid treatment is not merely for cleaning; it is a structural engineering tool. The process intentionally introduces structural defects into the precursor's crystal lattice.

Creating Essential Vacancies

Alongside general defects, the treatment generates specific vacancies. These are intentional voids or missing atoms within the material's framework.

These vacancies fundamentally alter the surface chemistry of the precursor. They transition the material from a passive support structure into an active participant in synthesis.

Optimizing for Metal Incorporation

Forming Adsorption Sites

The defects and vacancies created by the autoclave treatment serve a vital function. They act as ideal physical and chemical adsorption sites.

Anchoring Metal Ions

For a catalyst to be effective, metal ions must adhere securely to the precursor. The engineered defects provide the necessary anchoring points for this subsequent metal ion incorporation.

Without this hydrothermal treatment, the precursor surface would likely lack the specific "docking" sites required for high-density metal loading.

Understanding the Trade-offs

Balancing Structural Integrity

While creating defects is necessary for adsorption, it requires precise control. The goal is to induce enough imperfections to host metal ions without compromising the overall mechanical stability of the precursor.

Process Intensity

The use of high temperature and pressure increases the energy demand and complexity of synthesis. It is a more resource-intensive method compared to ambient treatments, justified only by the superior quality of the resulting adsorption sites.

Making the Right Choice for Your Goal

To maximize the effectiveness of your catalyst synthesis, consider your specific objectives when employing this equipment:

- If your primary focus is Increasing Metal Loading: Utilize the autoclave to maximize the density of structural defects, ensuring plentiful adsorption sites for the metal ions.

- If your primary focus is Precursor Activation: Use the high-pressure acid treatment to chemically modify inert surfaces, converting them into active vacancies ready for functionalization.

The Teflon-lined autoclave is the essential tool for transforming raw precursors into highly receptive, defect-rich scaffolds for advanced catalyst production.

Summary Table:

| Feature | Function in Catalyst Synthesis | Impact on Material |

|---|---|---|

| Teflon Lining | Provides chemical resistance to corrosive acids | Enables aggressive treatment without contamination |

| Hermetic Seal | Sustains high pressure and temperature | Forces deep chemical interaction into the lattice |

| Structural Engineering | Introduces intentional defects and vacancies | Creates active anchoring sites for metal ions |

| Surface Modification | Transitions material from passive to active | Increases surface energy and metal loading density |

Elevate Your Catalyst Synthesis with KINTEK

Precision matters in hydrothermal treatment. KINTEK’s Teflon-lined autoclaves are engineered to provide the stable, high-pressure environments required to create the specific structural defects your catalyst precursors need.

Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces tailored to your unique research requirements. Whether you are aiming to maximize metal loading or activate inert precursors, our equipment ensures uniform and repeatable results.

Ready to optimize your lab's high-temperature processes?

Contact KINTEK today for a consultation and let our experts help you choose the perfect system for your materials research.

Visual Guide

References

- Yihan Zhang, Hyesung Park. Lanthanum‐Induced Gradient Fields in Asymmetric Heterointerface Catalysts for Enhanced Oxygen Electrocatalysis. DOI: 10.1002/adma.202511117

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the function of a forced drying oven in SiOC coating conversion? Ensure Flawless Solvent Removal

- Why is the use of silver-containing active brazing alloys prohibited in TEGs? Prevent Semiconductor Degradation

- What is the primary role of a carbonization curing chamber? Unlock High Strength in Magnesium Slag Mortar

- What is a laboratory furnace and why is it important? Unlock Precision Heating for Your Lab

- Why is a constant temperature drying oven required for processing lignin residue? Ensure Superior Pore Dehydration

- Why is a vacuum drying oven required for processing MXene solutions and NPC@MoS2 nanostructures? Key Benefits Revealed

- Why is film uniformity important in semiconductor manufacturing? Ensure High Device Performance and Yield

- Why is annealing considered a core process in perovskite solar cell manufacturing? Unlock Peak Efficiency