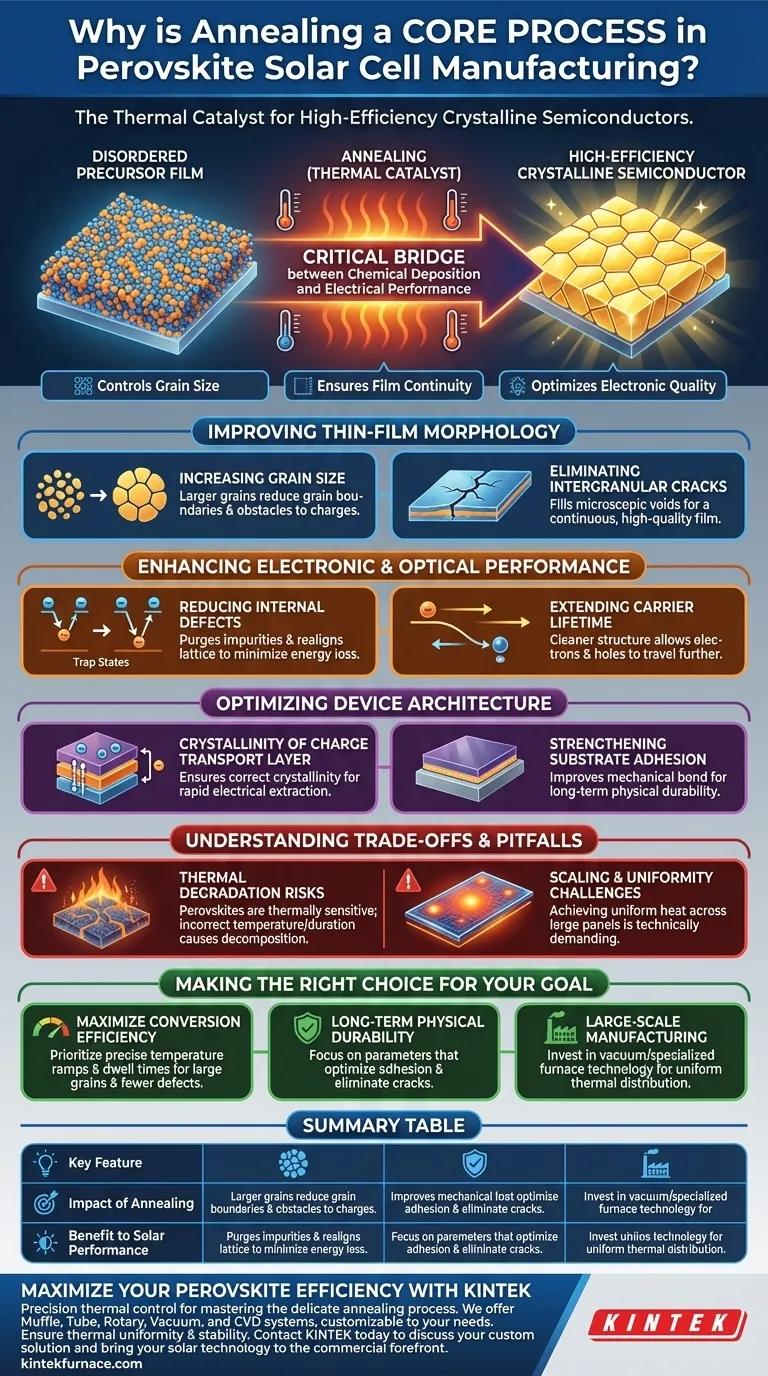

Annealing is the essential thermal catalyst that transforms a disordered precursor film into a high-efficiency crystalline semiconductor. It is considered a core process because it directly dictates the grain size, film continuity, and electronic quality of the perovskite layer. Without precise annealing, the resulting solar cell would suffer from poor charge transport and rapid degradation.

Annealing serves as the critical bridge between chemical deposition and electrical performance. By controlling the thermal environment, manufacturers can eliminate structural defects and optimize the light-harvesting properties of the perovskite film.

Improving Thin-Film Morphology

Increasing Grain Size

Annealing provides the energy necessary for crystal growth, leading to larger grain sizes within the perovskite structure. Larger grains are preferred because they reduce the total area of grain boundaries, which often act as obstacles to moving charges.

Eliminating Intergranular Cracks

The thermal process allows the material to settle and fill microscopic voids, effectively eliminating intergranular cracks. This creates a continuous, high-quality film that prevents electrical shunts and improves the overall structural integrity of the device.

Enhancing Electronic and Optical Performance

Reducing Internal Defects

Heat treatment helps purge impurities and realigns the atomic lattice to minimize internal defects. By reducing these "trap states," the cell can convert sunlight into electricity more efficiently with less energy loss.

Extending Carrier Lifetime

By creating a cleaner crystalline structure, annealing significantly extends the carrier lifetime. This allows electrons and "holes" to travel further through the material before recombining, which is a fundamental requirement for high-efficiency solar cells.

Optimizing Device Architecture

Crystallinity of the Charge Transport Layer

The impact of annealing extends beyond the perovskite layer itself to the charge transport layers. Proper thermal control ensures these layers have the correct crystallinity to facilitate the rapid movement of electricity out of the cell.

Strengthening Substrate Adhesion

Annealing improves the mechanical adhesion between the perovskite film and the underlying substrate. This bond is vital for the long-term physical durability of the solar panel, ensuring it can withstand environmental stressors.

Understanding the Trade-offs and Pitfalls

Thermal Degradation Risks

Perovskites are notoriously thermally sensitive compared to traditional silicon. If the annealing temperature is too high or the duration too long, the material can decompose, leading to a total loss of photovoltaic function.

Scaling and Uniformity Challenges

Achieving uniform temperature distribution across large-scale panels is technically demanding. Minor fluctuations in the thermal gradient can cause inconsistent grain sizes, leading to "hot spots" and reduced reliability in the final product.

Making the Right Choice for Your Goal

How to Apply This to Your Project

Proper annealing is a balancing act between achieving peak crystallinity and avoiding material decomposition.

- If your primary focus is Maximizing Conversion Efficiency: Prioritize precise temperature ramps and dwell times to maximize grain size and minimize electronic trap states.

- If your primary focus is Long-Term Physical Durability: Focus on the annealing parameters that optimize substrate adhesion and eliminate intergranular cracks to prevent moisture ingress.

- If your primary focus is Large-Scale Manufacturing: Invest in vacuum annealing or specialized furnace technology to ensure thermal uniformity across the entire surface area of the panel.

Mastering the annealing process is the single most important factor in transitioning perovskite research from the laboratory to a viable commercial product.

Summary Table:

| Key Feature | Impact of Annealing on Perovskite | Benefit to Solar Performance |

|---|---|---|

| Grain Size | Increases crystal size & reduces boundaries | Faster charge transport & higher efficiency |

| Film Morphology | Eliminates cracks and microscopic voids | Prevents shunts & improves structural integrity |

| Defect Density | Minimizes internal trap states | Reduces energy loss & extends carrier lifetime |

| Adhesion | Strengthens bond with substrate | Enhances long-term physical durability |

| Crystallinity | Optimizes charge transport layers | Facilitates rapid electrical extraction |

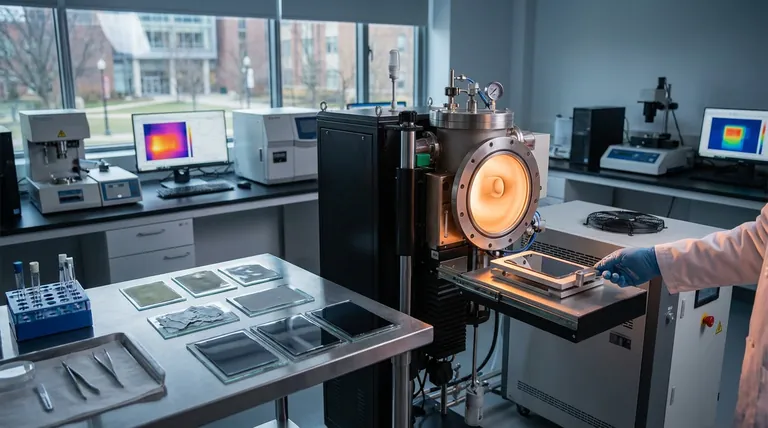

Maximize Your Perovskite Efficiency with KINTEK

Precision thermal control is the difference between a failing film and a high-performance solar cell. KINTEK provides the specialized equipment needed to master the delicate annealing process. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces—all fully customizable to your unique research or production requirements.

Whether you are scaling up for manufacturing or optimizing light-harvesting properties in the lab, our systems ensure the thermal uniformity and stability your perovskite projects demand. Contact KINTEK today to discuss your custom solution and bring your solar technology to the commercial forefront.

Visual Guide

References

- Shengcong Wu, Peng Gao. Temperature Matters: Enhancing Performance and Stability of Perovskite Solar Cells through Advanced Annealing Methods. DOI: 10.3390/chemistry6010010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a forced-air drying oven necessary for impregnated kaolin catalysts? Achieve Uniform Component Immobilization

- How does a high-precision PID temperature controller ensure the quality of biochar? Master Teff Husk Pyrolysis

- What is the role of a rotary evaporator in the extraction of isopulegyl acetate? Protect Purity and Stability

- What is the function of ball milling in Li-NASICON synthesis? Optimize Your Solid Electrolyte Performance

- Why do substrates undergo treatment in a high-temperature annealing furnace? Perfecting PtTe2/WTe2 Heterostructures

- Why is a pre-heated oxygen blowing system essential for chalcopyrite ignition? Ensure Precise Flash Smelting Simulation

- Why is the precision of an automatic temperature-controlled furnace critical in glass synthesis? Achieve 1350°C Accuracy

- What is the significance of applying full displacement constraints at fixed entry points? Ensure Thermal Accuracy