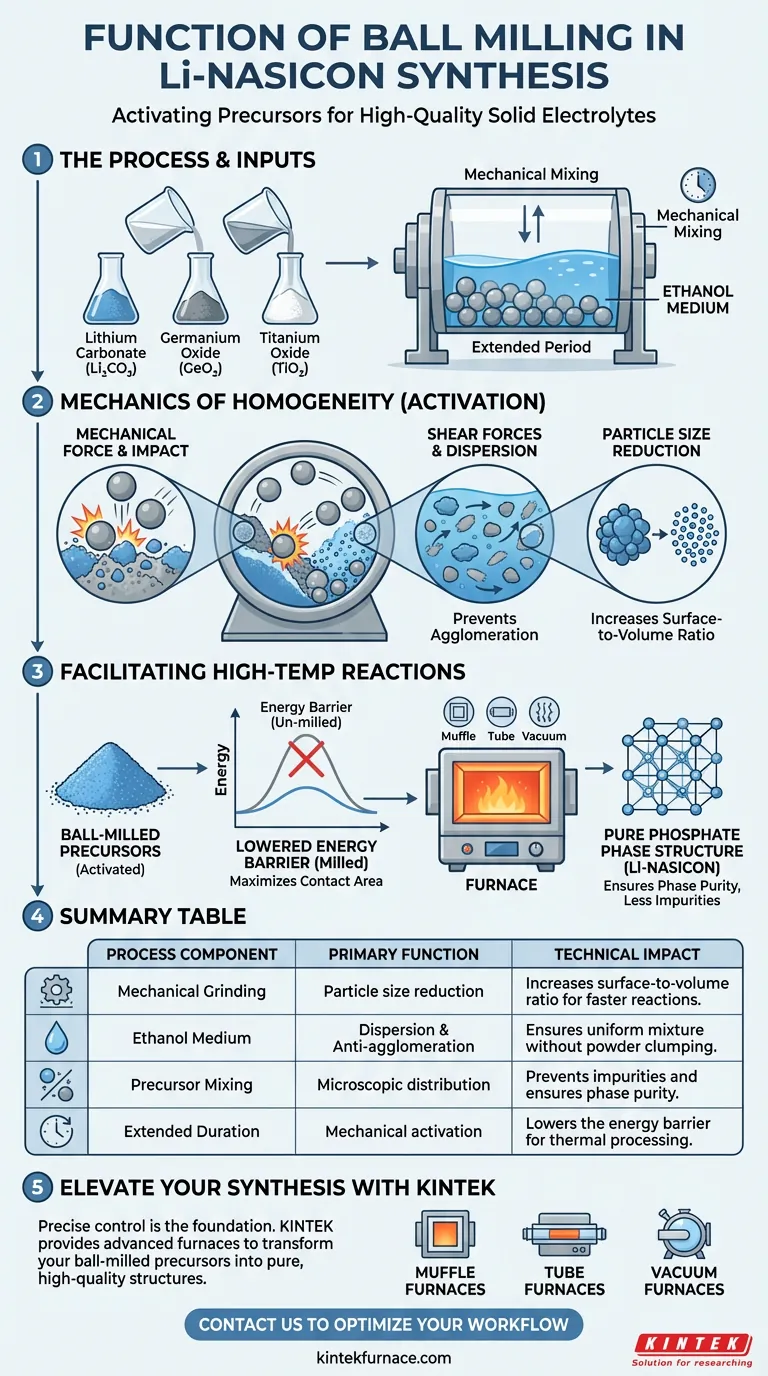

The primary function of the ball milling process in the synthesis of Li-NASICON solid electrolytes is to mechanically mix precursor powders—specifically lithium carbonate, germanium oxide, and titanium oxide—to achieve a uniform microscopic distribution. By conducting this grinding in an ethanol medium for an extended period, the process significantly reduces particle size and maximizes the contact area between chemical components.

Core Takeaway Ball milling is an activation step, not just a mixing method. By reducing particle size and increasing surface area, it lowers the energy barrier for subsequent reactions, ensuring the formation of a pure, high-quality phosphate phase structure during thermal treatment.

The Mechanics of Microscopic Homogeneity

Utilizing Mechanical Force

The process relies on the application of intense mechanical force to the precursor materials. As the milling media impacts the powders, it generates significant energy that physically breaks down the raw materials.

Shear and Impact Dynamics

While the primary goal is mixing, the mechanism involves high-energy impact and shear forces. This facilitates a "deep mixing" process that goes beyond simple blending, integrating the components at a microscopic level.

The Role of the Medium

The milling is performed in an ethanol medium rather than dry air. This liquid environment aids in dispersing the powders, preventing re-agglomeration, and ensuring the mixture remains uniform throughout the extended processing time.

Facilitating High-Temperature Reactions

Increasing Contact Area

The most critical physical change driven by ball milling is the reduction of particle size. Smaller particles possess a much higher surface-to-volume ratio, which dramatically increases the contact area between the lithium, germanium, and titanium precursors.

Lowering the Energy Barrier

High-temperature solid-state reactions require energy to initiate. By maximizing the contact area between reactants, ball milling lowers the activation energy barrier required for these chemical changes to occur.

Ensuring Phase Purity

The ultimate goal of this pre-treatment is to dictate the quality of the final product. A microscopically uniform mixture ensures that during the subsequent high-temperature reaction, a pure phosphate phase structure is formed, rather than a material ridden with impurities or incomplete reactions.

Critical Process Considerations

Requirement for Extended Processing

This is not a rapid procedure; it requires an "extended period" of milling to be effective. Short-cutting this step will result in insufficient mixing and larger particle sizes, compromising the final material.

Energy Intensity

The process utilizes high-speed rotation and mechanical impact to achieve the necessary shear forces. It is an energy-intensive prerequisite that must be maintained consistently to guarantee the reactants are sufficiently "activated" for the thermal treatment.

Optimizing the Synthesis Workflow

To ensure the highest quality Li-NASICON electrolyte, consider your specific processing goals:

- If your primary focus is Phase Purity: Ensure the milling duration is sufficient to achieve a truly microscopic uniform distribution, preventing the formation of secondary phases.

- If your primary focus is Reaction Efficiency: Prioritize the reduction of particle size to maximize contact area, which will facilitate easier and more complete reactions during the heating stage.

The success of your final solid electrolyte is directly proportional to the uniformity and particle size achieved during this initial milling stage.

Summary Table:

| Process Component | Primary Function | Technical Impact |

|---|---|---|

| Mechanical Grinding | Particle size reduction | Increases surface-to-volume ratio for faster reactions |

| Ethanol Medium | Dispersion & Anti-agglomeration | Ensures uniform mixture without powder clumping |

| Precursor Mixing | Microscopic distribution | Prevents impurities and ensures phase purity |

| Extended Duration | Mechanical activation | Lowers the energy barrier for thermal processing |

Elevate Your Materials Synthesis with KINTEK

Precise control over particle size and homogeneity is the foundation of high-performance Li-NASICON solid electrolytes. Backed by expert R&D and world-class manufacturing, KINTEK provides the advanced Muffle, Tube, and Vacuum furnaces required to transform your ball-milled precursors into pure, high-quality phosphate phase structures.

Whether you need customized systems for specialized lab research or high-temp production, our equipment is designed to meet your unique thermal processing needs. Contact us today to optimize your laboratory workflow!

Visual Guide

References

- Benjamin X. Lam, Gerbrand Ceder. Degradation Mechanism of Phosphate‐Based Li‐NASICON Conductors in Alkaline Environment. DOI: 10.1002/aenm.202403596

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What heat treatment conditions are required for SDSS2507 solution treatment? Achieve Precise 1100°C Thermal Profiles

- Why is a pre-heated oxygen blowing system essential for chalcopyrite ignition? Ensure Precise Flash Smelting Simulation

- What are the primary functions of a high-precision dilatometer in hot ductility? Optimize Steel Casting Precision

- How does calcination temperature affect CuO grain growth? Optimize Nanoporous Film Morphology and Crystallinity

- How does the temperature of the annealing process specifically influence the luminescence properties of ZnSe? Guide

- What is the primary function of a laboratory drying oven in cotton stalk pyrolysis? Ensure Data Integrity

- Why is the drying step using an industrial electric oven critical in catalyst preparation? Ensure Structural Integrity

- What types of materials can crucible furnaces melt? Unlock the Power of Versatile Melting