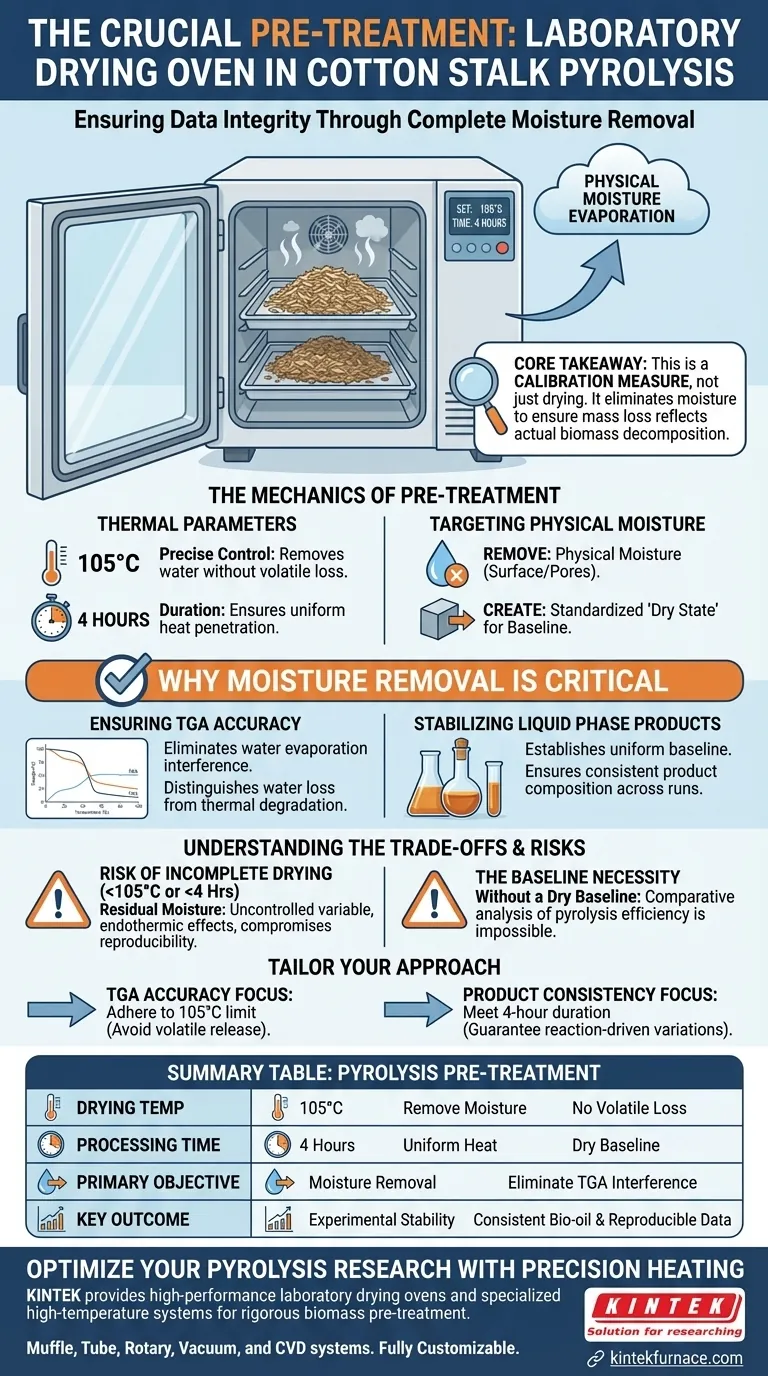

The primary function of a laboratory drying oven in this context is to completely remove physical moisture from crushed cotton stalk materials to ensure data integrity. By heating the biomass at 105°C for a duration of 4 hours, the process establishes a uniform experimental baseline before pyrolysis begins.

Core Takeaway This pre-treatment step is not merely about drying; it is a calibration measure. By eliminating moisture, you ensure that subsequent weight loss measurements reflect actual biomass decomposition rather than simple water evaporation.

The Mechanics of Pre-Treatment

Defining the Thermal Parameters

To achieve effective pre-treatment for cotton stalks, precise control is required. The laboratory drying oven must be set to 105°C.

The duration of this thermal exposure is equally critical. The material must be processed for 4 hours to ensure the heat penetrates the crushed biomass thoroughly.

Targeting Physical Moisture

The objective is the complete removal of physical moisture. This refers to water loosely bound to the surface or within the pores of the crushed stalks.

Unlike chemical water or volatiles released at higher temperatures, physical moisture is a variable that must be zeroed out. Removing it creates a standardized "dry state" for the raw material.

Why Moisture Removal is Critical

Ensuring TGA Accuracy

The most immediate impact of moisture is on Thermogravimetric Analysis (TGA). TGA measures precise changes in mass as temperature increases.

If moisture remains, its evaporation will register as weight loss. This interferes with the accuracy of the analysis, making it difficult to distinguish between water loss and the actual thermal degradation of the cotton stalk.

Stabilizing Liquid Phase Products

Pyrolysis produces bio-oil and other liquid phase components. The presence of variable amounts of water in the feedstock leads to inconsistent product compositions.

Pre-treatment establishes a uniform baseline. This ensures that the components of the liquid phase products remain consistent across different experimental runs.

Understanding the Trade-offs

The Risk of Incomplete Drying

If the 4-hour duration is shortened or the temperature drops below 105°C, residual moisture will persist. This introduces an uncontrolled variable into your experiment.

In high-temperature environments, residual moisture can cause endothermic effects (absorbing heat). This fluctuates the combustion temperature stability and compromises the reproducibility of your data.

The Baseline Necessity

Skipping or rushing this step renders comparative analysis impossible. Without a dry baseline, you cannot accurately compare the pyrolysis efficiency of different cotton stalk samples.

Making the Right Choice for Your Goal

To maximize the reliability of your pyrolysis experiments, tailor your approach based on your specific analytical needs:

- If your primary focus is TGA Accuracy: Strictly adhere to the 105°C limit to remove water without triggering premature release of volatiles or damaging the biomass structure.

- If your primary focus is Product Consistency: Ensure the 4-hour duration is fully met to guarantee that liquid phase product variations are due to reaction parameters, not feedstock moisture.

A rigorous drying protocol is the invisible foundation of reproducible pyrolysis data.

Summary Table:

| Parameter | Specification | Purpose in Pyrolysis |

|---|---|---|

| Drying Temperature | 105°C | Removal of physical moisture without volatile loss |

| Processing Time | 4 Hours | Ensures uniform heat penetration and dry baseline |

| Primary Objective | Moisture Removal | Eliminates mass loss interference in TGA |

| Key Outcome | Experimental Stability | Consistent bio-oil composition and reproducible data |

Optimize Your Pyrolysis Research with Precision Heating

Don't let residual moisture compromise your data integrity. KINTEK provides high-performance laboratory drying ovens and specialized high-temperature systems designed for the rigorous demands of biomass pre-treatment and thermal analysis.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory needs. Whether you are focusing on TGA accuracy or liquid-phase product consistency, our equipment delivers the thermal stability your research deserves.

Ready to elevate your experimental results? Contact KINTEK today to find the perfect customized heating solution for your lab!

Visual Guide

References

- Hussien Elshareef, Yuguang Zhou. Investigation of Bio-Oil and Biochar Derived from Cotton Stalk Pyrolysis: Effect of Different Reaction Conditions. DOI: 10.3390/resources14050075

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is a vacuum oven required during the preparation of Al-CNTs/h-BN composites? Prevent Defects & Ensure Purity

- How do lab furnaces simulate fire environments for UHPFRC testing? Achieving ISO834 Standard Compliance

- What role does sodium silicate (Na2SiO3) play as a phase transition additive? Optimize Molten Salt Separation

- What is the function of magnetron sputtering equipment in Diamond/Cu composites? Enhance Bonding with Precision Coating

- What task does a laboratory blast drying oven perform in the preparation of copper oxide precursors? Prevent Clumping

- What are the advantages of using h-BN vs SiO2 for WTe2 heterostructures? Enhance Electronic and Structural Integrity

- What are the energy consumption considerations when choosing between separate or combined debinding and sintering furnaces? Optimize Your Process Efficiency

- What process problems are addressed by using a walking-beam furnace model? Solve Clad Plate Thermal Stress Challenges