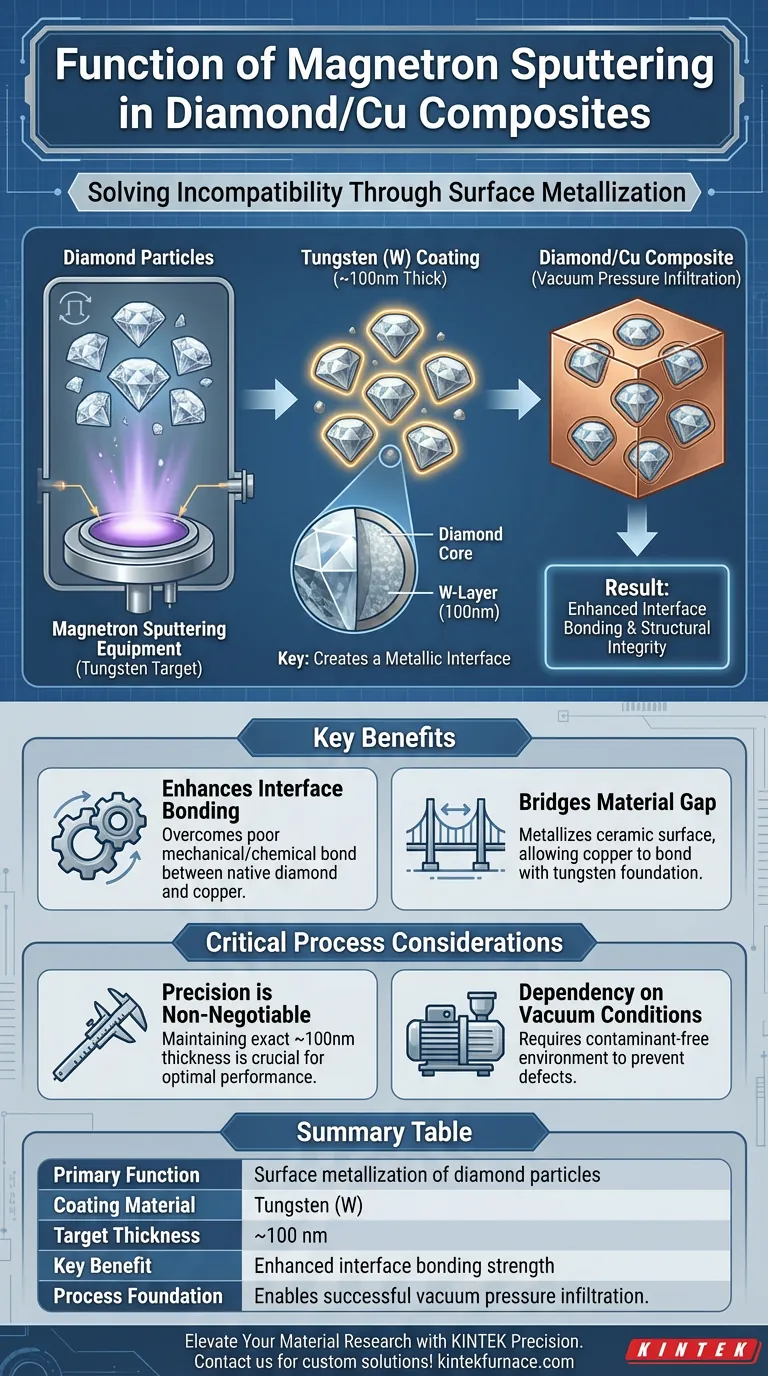

Magnetron sputtering equipment functions as the primary tool for surface metallization in the fabrication of Diamond/Cu composites. Its specific role is to deposit a tungsten (W) thin film, approximately 100nm thick, directly onto the diamond particles. This coating acts as a crucial bridge, altering the surface chemistry of the diamond to prepare it for integration with a metal matrix.

Core Takeaway The equipment solves the fundamental incompatibility between diamond and copper by creating a metallic tungsten interface. This ~100nm layer significantly enhances bonding strength and provides the necessary foundation for successful vacuum pressure infiltration.

The Mechanics of Surface Metallization

Deposition of the Tungsten Layer

The magnetron sputtering process is used to coat non-metallic diamond particles with a metallic layer. Specifically, it deposits tungsten (W) onto the diamond surface.

Achieving Nanoscale Precision

The equipment allows for high-precision thickness control. The target thickness for this application is approximately 100nm. This specific thickness provides adequate coverage without adding excessive bulk to the composite reinforcement.

The Impact on Composite Integrity

Enhancing Interface Bonding

The primary outcome of using magnetron sputtering is a dramatic improvement in interface bonding strength. Native diamond surfaces often struggle to bond mechanically or chemically with copper matrices.

Bridging the Material Gap

By coating the diamond with tungsten, the equipment effectively "metallizes" the ceramic surface. This allows the copper matrix to interact with a tungsten surface rather than a carbon surface, facilitating a stronger connection.

Enabling Vacuum Pressure Infiltration

The metallization process is not an end in itself but a preparation step. The tungsten coating serves as a critical foundation for the subsequent manufacturing stage: vacuum pressure infiltration. Without this surface modification, the infiltration process would likely result in poor wetting and weak structural integrity.

Critical Process Considerations

Precision is Non-Negotiable

The reference highlights a specific thickness of 100nm. This implies that deviations—coatings that are too thin or too thick—may compromise the interface. The magnetron sputtering equipment must be calibrated to maintain this exact tolerance to ensure the bonding benefits are realized.

Dependency on Vacuum Conditions

As this is a sputtering process, the quality of the tungsten film relies heavily on the vacuum environment. Any contamination during this stage could disrupt the metallization, leading to defects in the final Diamond/Cu composite.

Optimizing Your Composite Preparation

The use of magnetron sputtering is a strategic step to overcome the natural incompatibility of your raw materials.

- If your primary focus is mechanical strength: Ensure the equipment is calibrated to deliver a uniform 100nm tungsten layer to maximize interface bonding.

- If your primary focus is process reliability: View the sputtering phase as a prerequisite for infiltration; a poor coating here will lead to failure in the subsequent vacuum pressure step.

Reliable surface metallization is the key to unlocking the full potential of Diamond/Cu composites.

Summary Table:

| Feature | Specification/Role |

|---|---|

| Primary Function | Surface metallization of diamond particles |

| Coating Material | Tungsten (W) |

| Target Thickness | ~100 nm |

| Key Benefit | Enhanced interface bonding strength |

| Process Foundation | Enables successful vacuum pressure infiltration |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your Diamond/Cu composites with KINTEK’s industry-leading technology. Backed by expert R&D and manufacturing, KINTEK offers high-performance Magnetron Sputtering systems, Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your unique research or production needs.

Whether you require nanoscale thickness control or specialized high-temperature lab furnaces, our engineering team is ready to deliver the reliability your project demands. Contact us today to discuss your custom solution and see how we can optimize your material integration process!

Visual Guide

References

- Ying Zhou, Degan Xiong. An Investigation on the Spark Plasma Sintering Diffusion Bonding of Diamond/Cu Composites with a Cr Interlayer. DOI: 10.3390/ma17246026

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What core processing conditions does a laboratory high-temperature oven provide? Optimize Geopolymer Curing Results

- What is the function of an industrial electric furnace in Al-Cu 224 alloy preparation? Optimize Your Metal Production

- Why is a specialized roasting simulation device necessary? Optimize Iron Ore Pellet Quality and Strength

- How does a high-precision infrared temperature measurement system influence the sintering quality of Al2O3/TiC ceramics?

- What is the technical purpose of drying NaNbO3:Pr3+ precursors at 60 °C? Optimize Your Powder Synthesis

- What role does graphite paper play in magnesium vapor condensation experiments? A Key to High-Purity Collection & Analysis

- How do precision electric drying ovens control the precipitation of strengthening phases in recycled aluminum alloys?

- What is the specific function of laboratory electric heating devices in solid-state hydrogen storage? Optimize Thermal Management