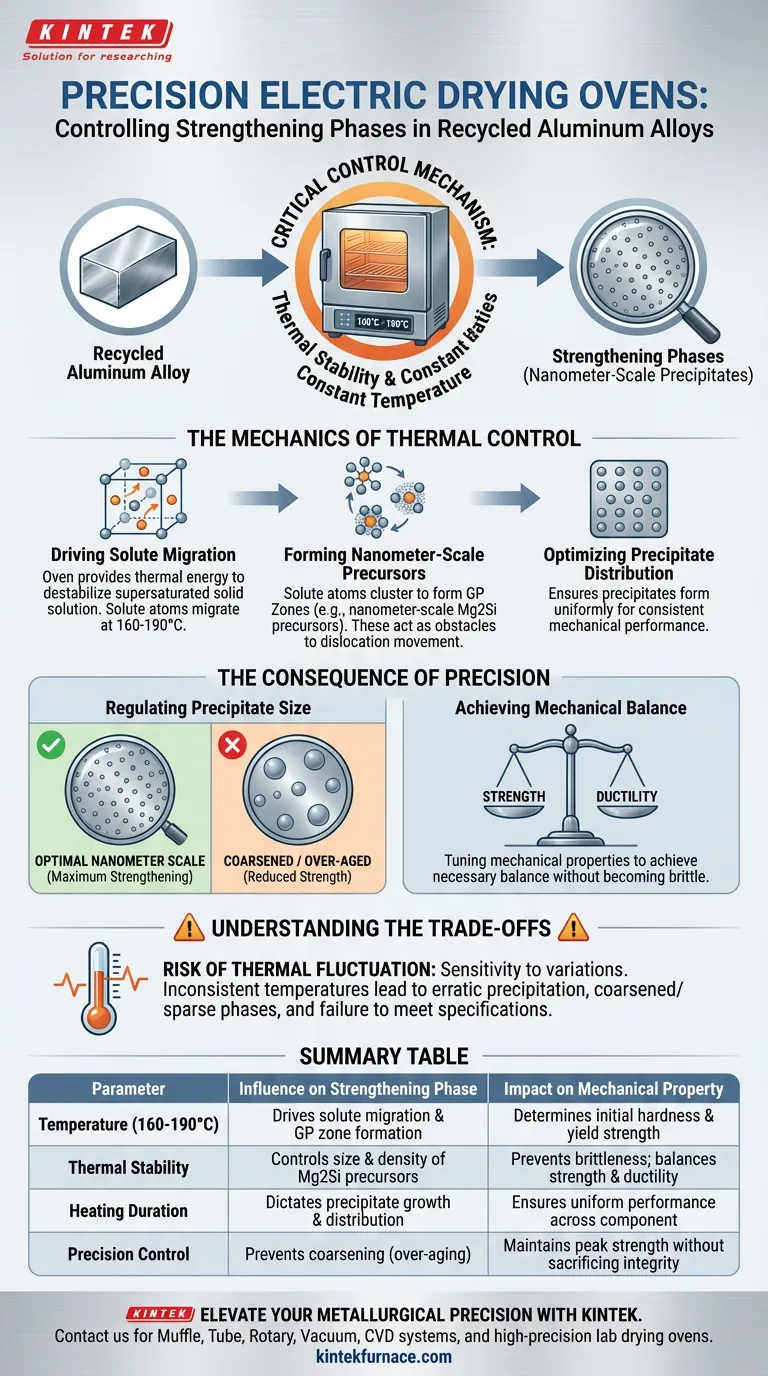

Precision electric drying ovens act as the critical control mechanism for artificially aging recycled aluminum alloys by maintaining a strictly constant temperature environment. By holding the alloy between 160°C and 190°C for extended periods, the oven drives solute atoms out of a supersaturated solid solution to form specific nanometer-scale strengthening phases.

The primary value of the oven is not just heating, but thermal stability. By ensuring the temperature remains constant, the oven dictates the size, density, and distribution of precipitates, which is the sole factor determining whether the final alloy achieves the necessary balance of strength and ductility.

The Mechanics of Thermal Control

Driving Solute Migration

The fundamental function of the oven is to provide the thermal energy required to destabilize the supersaturated solid solution.

At maintained temperatures of 160°C to 190°C, solute atoms become mobile enough to migrate out of the solution.

This controlled migration is the first step in altering the internal structure of the recycled alloy.

Forming Nanometer-Scale Precursors

As solute atoms cluster together, they form specific structural precursors known as GP zones (Guinier-Preston zones).

The reference specifically identifies the formation of nanometer-scale Mg2Si precursors during this phase.

These microscopic structures act as obstacles to dislocation movement within the metal, which is the physical mechanism that increases the material's strength.

Optimizing Precipitate Distribution

The effectiveness of the strengthening process relies on the density and distribution of these phases.

A precision oven ensures that these precipitates form uniformly throughout the material rather than clustering unevenly.

Uniform distribution is essential for consistent mechanical performance across the entire component.

The Consequence of Precision

Regulating Precipitate Size

Thermal precision directly influences the final size of the precipitated phases.

If the temperature is controlled accurately, the precipitates remain at the optimal nanometer scale required for maximum strengthening.

Achieving Mechanical Balance

The ultimate goal of using a precision oven is to tune the mechanical properties of the alloy.

The process aims to achieve a specific balance between strength and ductility.

By controlling the precipitation variables, the oven ensures the alloy becomes strong enough to bear loads without becoming brittle.

Understanding the Trade-offs

The Risk of Thermal Fluctuation

The primary trade-off in artificial aging is the sensitivity of the microstructure to temperature variations.

If the oven fails to maintain the strict 160°C to 190°C range, the precipitation process can become erratic.

Impact on Alloy Performance

Inconsistent temperatures can lead to precipitates that are either too large (coarsened) or too sparse.

This results in a material that fails to meet the target specifications for either strength or ductility, rendering the recycled alloy unsuitable for high-stress applications.

Making the Right Choice for Your Goal

To maximize the utility of recycled aluminum alloys, you must align your thermal processing with your desired mechanical outcome.

- If your primary focus is maximum strength: Prioritize strict temperature stability to maximize the density of fine nanometer-scale Mg2Si precursors.

- If your primary focus is balanced ductility: Ensure the oven prevents temperature spikes that could lead to rapid coarsening of the precipitate phases.

Precision thermal control is the bridge that transforms raw chemical potential into reliable mechanical performance.

Summary Table:

| Parameter | Influence on Strengthening Phase | Impact on Mechanical Property |

|---|---|---|

| Temperature (160-190°C) | Drives solute migration and GP zone formation | Determines initial hardness and yield strength |

| Thermal Stability | Controls size and density of Mg2Si precursors | Prevents brittleness; balances strength and ductility |

| Heating Duration | Dictates precipitate growth and distribution | Ensures uniform performance across the component |

| Precision Control | Prevents coarsening (over-aging) | Maintains peak strength without sacrificing integrity |

Elevate Your Metallurgical Precision with KINTEK

Precision is the difference between high-performance material and wasted scrap. At KINTEK, we understand that thermal stability is the soul of artificial aging. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside our high-precision lab drying ovens—all fully customizable to meet your unique metallurgical needs.

Whether you are optimizing nanometer-scale Mg2Si precursors or perfecting the ductility of recycled alloys, our equipment provides the unwavering temperature control required for consistent results. Contact us today to find the perfect thermal solution for your lab!

Visual Guide

References

- Heat Treatment Analysis and Mechanical Characterization of a Recycled Gravity Die Cast EN 42000 Alloy. DOI: 10.3390/met15070726

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1400℃ Muffle Oven Furnace for Laboratory

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

People Also Ask

- What function does a high-temperature furnace serve in alumina nanopowder decarbonization? Ensure Purity & Performance

- What are the key requirements for steel materials in high-speed rail, nuclear power, and aerospace industries? Unlock High-Performance Steel Solutions

- Why is high-temperature stability important for Cu2O substrates? Ensure Long-Term Electrocatalytic Efficiency

- Why is precise temperature control critical for drying carbon nanotube films? Achieve Perfect 80°C Thermal Stability

- What are the advantages of the sol-gel nitrate combustion method? Achieve Atomic-Level Purity in Oxide Synthesis

- What experimental conditions does a high-temperature continuous flow fixed-bed reactor provide for Zn-Cr catalysts?

- Why is programmable heating equipment necessary for composite curing? Master Thermal Control for Superior Strength

- How does a Flash Sintering (FS) system improve efficiency? Unlock Rapid Production for Titanium Diboride Composites