Precise temperature control is essential for maintaining the delicate balance between effective dehydration and material preservation. During the drying phase of carbon nanotube films, the laboratory oven must be maintained at approximately 80°C to remove water and residual solvents without destroying the underlying filter membrane or degrading the nanotubes through oxidation.

Successful drying is not just about heat; it is about preservation. Maintaining a steady 80°C ensures the film is fully dehydrated for hot-pressing while preventing thermal damage to the sensitive filter substrate and the carbon structure.

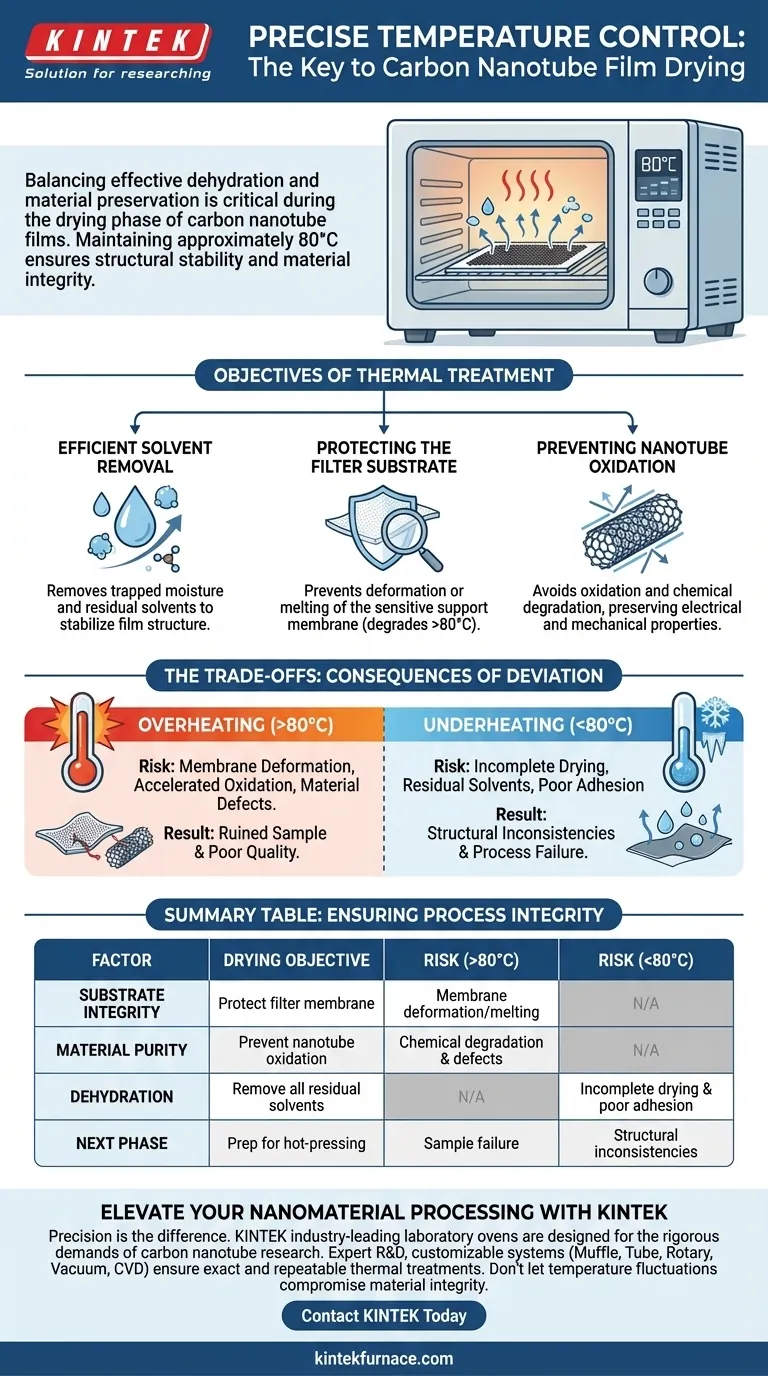

The Objectives of Thermal Treatment

Efficient Solvent Removal

The primary purpose of the oven cycle is to remove moisture. After the washing process, water and residual solvents remain trapped within the nanotube film.

Heating the material drives these solvents off. This step is critical to stabilize the film structure before further manipulation.

Protecting the Filter Substrate

Carbon nanotube films are typically deposited onto a filter membrane. This membrane acts as the foundational support during the washing and drying phases.

However, this substrate is highly sensitive to heat. If the temperature exceeds the specific 80°C target, the membrane can deform or melt, potentially ruining the sample.

Preventing Nanotube Oxidation

Carbon nanotubes themselves are vulnerable during thermal processing. While they are robust materials, they are susceptible to oxidation at elevated temperatures.

Controlled heating prevents excessive oxidation. Preserving the chemical integrity of the nanotubes is vital for maintaining their desired electrical and mechanical properties.

Understanding the Trade-offs

The Risk of Overheating

Pushing temperatures beyond the recommended 80°C might seem like a way to speed up drying, but it is destructive. The immediate risk is damage to the filter membrane, which compromises the physical support of the film.

Furthermore, high heat accelerates oxidation. This introduces defects into the carbon nanotubes, degrading the quality of the final material.

The Consequence of Inadequate Heat

Conversely, failing to maintain 80°C results in incomplete drying. If residual water or solvents remain in the film, the material is not properly prepared for the next step.

This creates issues during the subsequent hot-pressing process. A film that retains moisture may not compact or adhere correctly, leading to structural inconsistencies.

Ensuring Process Integrity

To maximize the quality of your carbon nanotube films, precise thermal regulation is the deciding factor.

- If your primary focus is structural stability: Ensure the oven does not exceed 80°C to prevent warping or destruction of the sensitive filter membrane.

- If your primary focus is material purity: Maintain strict temperature limits to avoid oxidation that degrades the intrinsic properties of the carbon nanotubes.

- If your primary focus is process continuity: Verify complete dehydration at the target temperature to ensure the material is ready for the hot-pressing phase.

Precision in the drying phase is the safeguard that ensures your raw material becomes a viable, high-performance film.

Summary Table:

| Factor | Drying Objective | Risk of Overheating (>80°C) | Risk of Underheating (<80°C) |

|---|---|---|---|

| Substrate Integrity | Protect filter membrane | Membrane deformation/melting | N/A |

| Material Purity | Prevent nanotube oxidation | Chemical degradation & defects | N/A |

| Dehydration | Remove all residual solvents | N/A | Incomplete drying & poor adhesion |

| Next Phase | Prep for hot-pressing | Sample failure | Structural inconsistencies |

Elevate Your Nanomaterial Processing with KINTEK

Precision is the difference between a high-performance film and a ruined sample. KINTEK provides industry-leading laboratory ovens designed for the rigorous demands of carbon nanotube research. Backed by expert R&D and manufacturing, we offer a full range of customizable Muffle, Tube, Rotary, Vacuum, and CVD systems to ensure your thermal treatments are exact and repeatable.

Don't let temperature fluctuations compromise your material integrity. Contact KINTEK today to discover how our specialized high-temperature lab furnaces can optimize your drying and synthesis workflows.

Visual Guide

References

- Nimra Naeem, Muhammad Farooq. Facile development of carbon nanotube (CNT)-based flexible thermoelectric materials for energy-harvesting applications. DOI: 10.1039/d4ra02914c

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is a glove box necessary for aluminum foil pre-lithiation? Ensure Purity in Anode Development

- How does the 1600°C range influence biomass microstructure? Transform Carbon into High-Performance Graphite

- What is the role of temperature control in MCM-41 synthesis? Master Precision Pore Engineering

- What is the function of a precise heating system during the hydrolysis of palm kernel oil? Optimize Your Fatty Acid Yield

- What are the advantages of using a vacuum drying oven for ZIF67/MXene? Protect Your Composite Integrity

- Why is a forced-air drying oven necessary for impregnated kaolin catalysts? Achieve Uniform Component Immobilization

- How does diamond benefit 5G technology? Unlock Peak Performance with Superior Thermal Management

- What is the necessity of preheating reinforcement materials? Eliminate Defects in Aluminum Alloys