The 1600°C environment of a high-temperature furnace drives a critical transformation in carbonized biomass by forcing deep deoxygenation and rearranging disordered atoms into a highly ordered sp2 hybridized lattice. This intense thermal processing, known as graphitization, is the defining factor that turns raw organic material into high-performance conductive carbon.

The extreme heat of 1600°C provides the necessary activation energy to establish a stable and continuous conductive path within the material. This structural evolution is the primary driver behind the superior electrical and thermal performance found in advanced materials like nano carbon spheres.

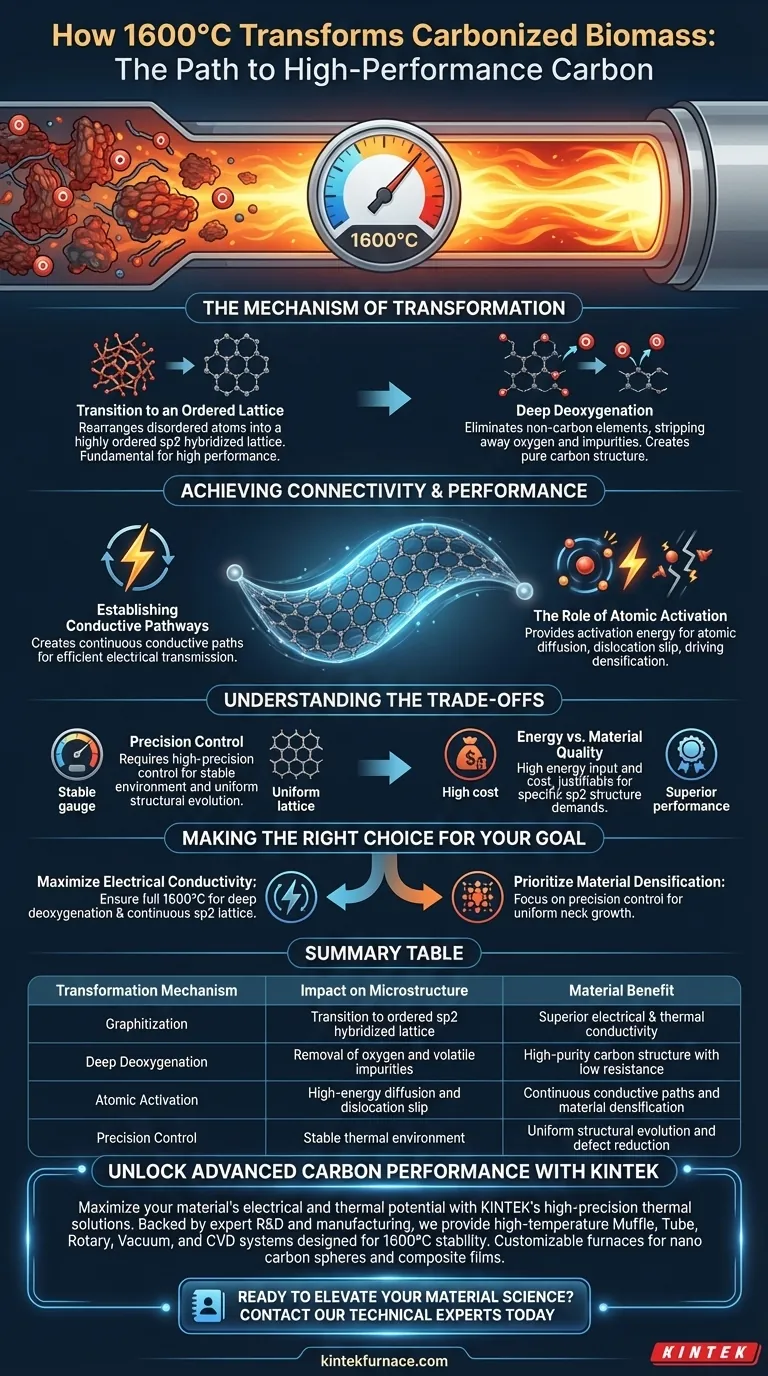

The Mechanism of Microstructural Transformation

Transitioning to an Ordered Lattice

At lower temperatures, carbonized biomass retains a disordered atomic structure. The 1600°C threshold supplies enough energy to rearrange these carbon atoms.

This rearrangement forms a highly ordered sp2 hybridized lattice, effectively shifting the material structure toward graphite. This ordering is the fundamental prerequisite for high-performance applications.

Deep Deoxygenation

To achieve a pure carbon structure, non-carbon elements must be eliminated. The 1600°C range enables deep deoxygenation, stripping away oxygen and other volatile impurities.

This purification process removes atomic "clutter" that would otherwise impede electron flow and phonon transport.

Achieving Connectivity and Performance

Establishing Conductive Pathways

The primary benefit of this microstructural change is the creation of a continuous conductive path.

In materials like nano carbon spheres used in composite films, this continuity allows for efficient electrical transmission. Without this high-temperature treatment, the material would remain resistive and insulating.

The Role of Atomic Activation

The furnace does not simply heat the material; it provides the activation energy required for atomic diffusion.

According to supplementary technical data, this environment allows for dislocation slip and the formation of stacking faults. These atomic-level movements are necessary to expand contact areas between particles and drive densification.

Understanding the Trade-offs

The Necessity of Precision Control

Reaching 1600°C is insufficient if the temperature fluctuates. High-precision thermal control is required to stabilize the environment.

Without this stability, the atomic diffusion processes (such as the formation of Shockley partial dislocations) become unpredictable. This can lead to uneven densification or structural defects rather than a uniform conductive lattice.

Energy vs. Material Quality

Operating at 1600°C requires significant energy input and specialized equipment capable of maintaining stability.

While this maximizes electrical and thermal performance, it represents a high manufacturing cost. It is only justifiable when the application demands the specific sp2 hybridized structure that lower temperatures cannot produce.

Making the Right Choice for Your Goal

To leverage high-temperature processing effectively, align your furnace parameters with your specific material requirements:

- If your primary focus is maximum electrical conductivity: Ensure your process reaches the full 1600°C range to guarantee deep deoxygenation and the formation of a continuous sp2 lattice.

- If your primary focus is material densification: Prioritize the precision of your temperature control system to stabilize atomic diffusion and facilitate uniform neck growth between particles.

The 1600°C threshold is not just a temperature setting; it is the catalyst that physically reconstructs biomass into a functional, high-performance electronic material.

Summary Table:

| Transformation Mechanism | Impact on Microstructure | Material Benefit |

|---|---|---|

| Graphitization | Transition to ordered sp2 hybridized lattice | Superior electrical & thermal conductivity |

| Deep Deoxygenation | Removal of oxygen and volatile impurities | High-purity carbon structure with low resistance |

| Atomic Activation | High-energy diffusion and dislocation slip | Continuous conductive paths and material densification |

| Precision Control | Stable thermal environment | Uniform structural evolution and defect reduction |

Unlock Advanced Carbon Performance with KINTEK

Maximize your material's electrical and thermal potential with KINTEK’s high-precision thermal solutions. Backed by expert R&D and manufacturing, we provide high-temperature Muffle, Tube, Rotary, Vacuum, and CVD systems specifically designed to maintain the 1600°C stability required for deep deoxygenation and sp2 lattice formation. Whether you are scaling production for nano carbon spheres or developing custom composite films, our customizable furnaces deliver the exact activation energy your materials demand.

Ready to elevate your material science? Contact our technical experts today to find the perfect furnace for your unique needs.

Visual Guide

References

- Junchao Ren, Qingfa Zhang. All‐Biomass Nanocomposite Films via Facile and Sustainable Design Procedure for Thermal Management and Electromagnetic Interference Shielding. DOI: 10.1002/advs.202510372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the function of a drying oven during the chemical activation of biochar? Optimize Your Porous Carbon Structure

- How does a vacuum drying oven contribute to the quality of crosslinked precursors? Expert Guide to Material Integrity

- How does a hybrid microwave sintering furnace compare to traditional furnaces? Optimize BZT Ceramic Production

- What is the purpose of treating EAF dust in a dryer? Ensure Precise Material Characterization & Data Integrity

- What are the benefits of using graphite or stainless steel crucibles for Rubidium Chloride? Ensure Maximum Purity

- How does the temperature of the annealing process specifically influence the luminescence properties of ZnSe? Guide

- How does high-purity argon gas affect the production of ultrafine magnesium powder in evaporation-condensation methods? Master Particle Size Control

- What are the drawbacks of large industrial ovens? Avoid Costly Inefficiencies and Boost Productivity