A hybrid microwave sintering furnace fundamentally alters the production of Barium Zirconium Titanate (BZT) by shifting from external thermal conduction to internal volumetric heating. For BZT ceramics, this approach drastically reduces processing time to as little as 30 minutes while lowering necessary sintering temperatures, offering a distinct efficiency advantage over traditional furnaces.

The Core Insight By leveraging microwave energy to directly couple with the material, hybrid sintering achieves rapid densification that conventional radiant heat cannot match. This process produces BZT ceramics with superior dielectric and ferroelectric properties by effectively inhibiting grain coarsening and ensuring microstructural uniformity.

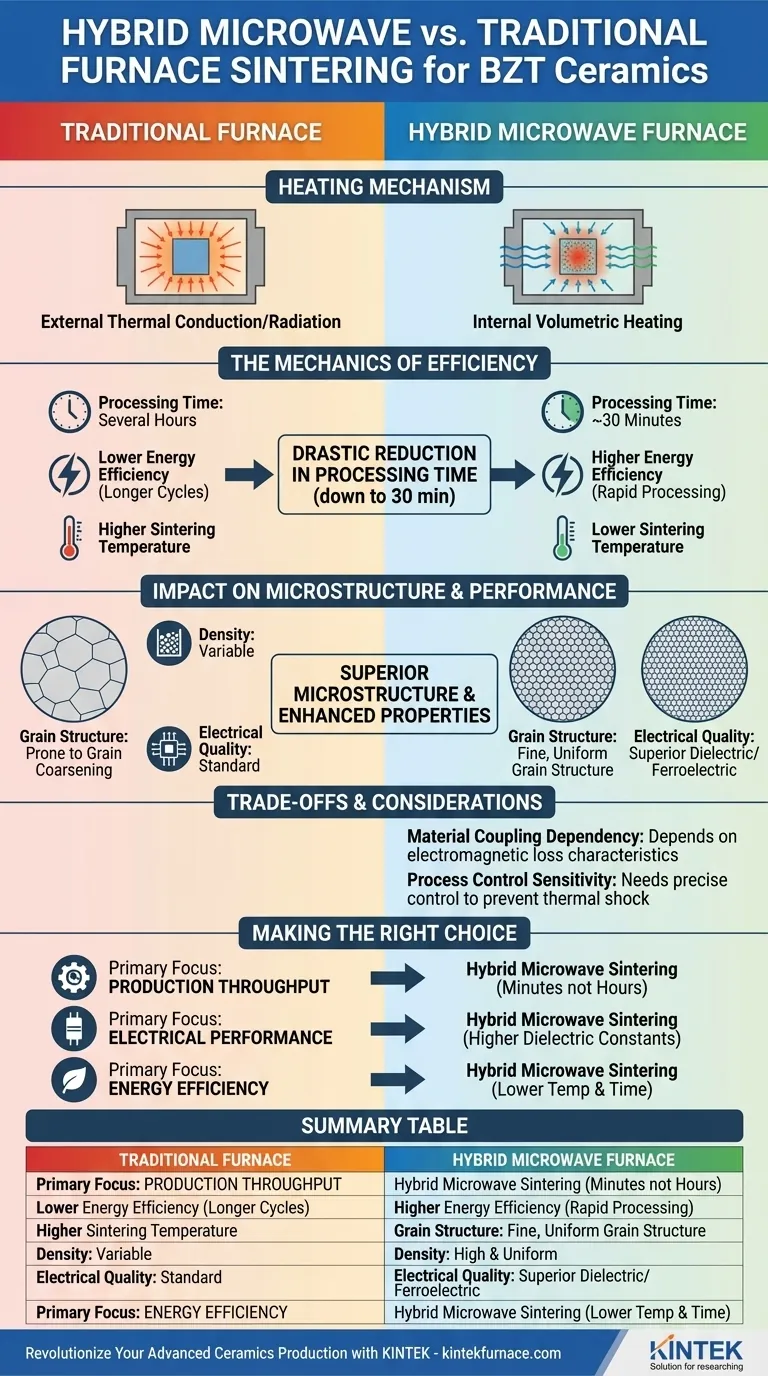

The Mechanics of Efficiency

Volumetric Heating Mechanism

Unlike traditional furnaces that heat a sample from the outside in (conduction), hybrid microwave furnaces utilize volumetric heating.

The microwave energy directly couples with the BZT material, generating heat internally throughout the entire volume of the ceramic simultaneously.

Drastic Reduction in Processing Time

The most immediate operational difference is the speed of the thermal cycle.

While traditional sintering involves long ramp-up and hold times, hybrid microwave sintering can complete the process in as little as 30 minutes.

This rapid processing capability significantly lowers energy consumption and increases production throughput compared to conventional methods.

Impact on Microstructure and Performance

Inhibiting Grain Coarsening

In traditional sintering, prolonged exposure to high temperatures often allows grains within the ceramic to grow excessively (coarsening).

The rapid heating rates of the hybrid microwave process deny the material the time required for this coarsening to occur.

This results in a finer, more controlled grain structure, which is critical for high-performance ceramics.

Enhanced Density and Uniformity

Because heat is generated uniformly from within the material, thermal gradients are minimized.

This leads to enhanced density and improved microstructural uniformity across the entire BZT sample.

Defects associated with uneven heating, common in conventional furnaces, are significantly reduced.

Superior Electrical Properties

The physical improvements in the ceramic's structure directly translate to functional performance.

The high density and fine grain structure attained through this method result in improved dielectric constants and better ferroelectric properties.

Understanding the Trade-offs

Material Coupling Dependency

It is important to note that the efficiency of this method relies on the material’s ability to "couple" with microwave energy.

The process depends on the specific electromagnetic loss characteristics of the BZT material to generate heat; materials with poor coupling properties may not sinter as effectively without auxiliary heating aids (hence the "hybrid" nature of some furnace designs).

Process Control Sensitivity

The extreme speed of the process introduces a need for precise control.

Because the heating is so rapid, maintaining thermal equilibrium is critical to prevent thermal shock, although the volumetric nature of the heating mitigates this risk better than rapid external heating would.

Making the Right Choice for Your Goal

When deciding between hybrid microwave sintering and traditional methods for BZT production, consider your specific performance metrics.

- If your primary focus is Production Throughput: Hybrid microwave sintering is the superior choice, reducing cycle times to minutes rather than hours.

- If your primary focus is Electrical Performance: The hybrid method is preferable, as it yields higher dielectric constants and ferroelectric properties through better microstructural control.

- If your primary focus is Energy Efficiency: The significant reduction in temperature and time makes hybrid microwave sintering the more sustainable option.

Ultimately, for BZT ceramics, hybrid microwave sintering offers a technical upgrade over traditional methods by aligning rapid processing speeds with superior material quality.

Summary Table:

| Feature | Traditional Furnace | Hybrid Microwave Furnace |

|---|---|---|

| Heating Method | External Conduction/Radiation | Internal Volumetric Heating |

| Sintering Time | Several Hours | ~30 Minutes |

| Microstructure | Prone to Grain Coarsening | Fine, Uniform Grain Structure |

| Density | Variable | High & Uniform |

| Energy Efficiency | Lower (Longer Cycles) | Higher (Rapid Processing) |

| Electrical Quality | Standard | Superior Dielectric/Ferroelectric |

| Primary Benefit | Simple, Established Process | High Throughput & Material Quality |

Revolutionize Your Advanced Ceramics Production with KINTEK

Are you looking to enhance the dielectric performance and density of your BZT materials while cutting energy costs? KINTEK provides state-of-the-art thermal solutions backed by expert R&D and manufacturing.

Our range of specialized equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—can be fully customized to meet your unique sintering requirements. Whether you need the precision of a controlled atmosphere or the efficiency of rapid thermal processing, our high-temperature lab furnaces ensure your research and production achieve maximum microstructural uniformity.

Ready to upgrade your lab's capabilities? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- T. Avanish Babu, W. Madhuri. Energy storage and catalytic behaviour of cmWave assisted BZT and flexible electrospun BZT fibers for energy harvesting applications. DOI: 10.1038/s41598-024-52705-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- Why is a low-temperature annealing treatment necessary for porous gold microspheres? Ensure Structural Integrity

- Why is 800 °C necessary for NCNTs? Unlock Superior Conductivity and Ion Transport

- How does a high-precision temperature control system contribute to NMC synthesis? Precision in XRD In-Situ Experiments

- Why is a high-pressure autoclave essential for nanomaterials? Unlock Superior Crystallinity and Quantum Yield

- What is the primary function of a vacuum drying oven? Key to Composite Anode Slurry Preparation

- Why is pressure molding and high-temperature sintering required for UO2-ZrO2? Mastering Material Density

- Why is a high-precision heating/cooling stage important for 2D In2Se3 studies? Secure Precise Phase Transition Data

- Why is an industrial forced air drying oven required for drying banana slices? Unlock Precision & Nutritional Quality