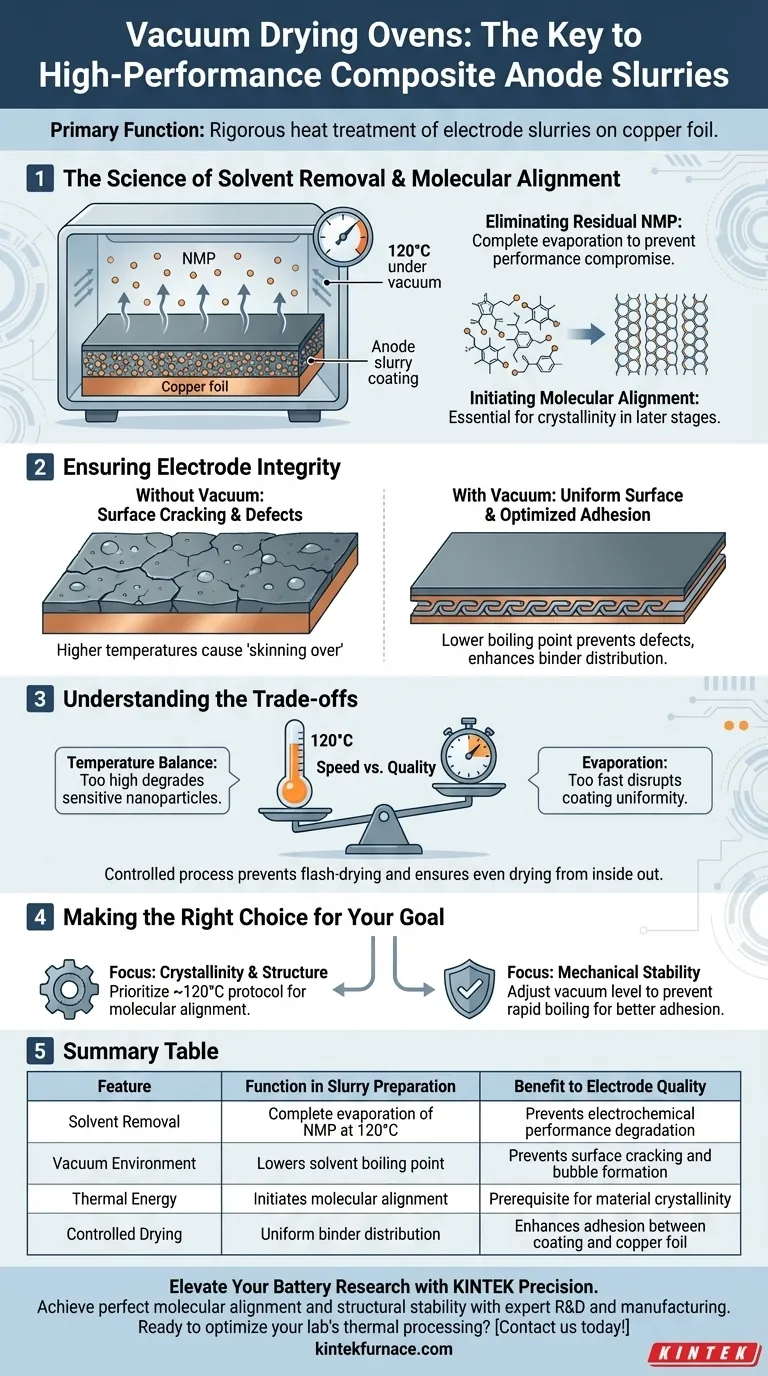

The primary function of a vacuum drying oven in the preparation of composite anode slurries is the rigorous heat treatment of electrode slurries coated onto copper foil current collectors. Operating at specific temperatures, such as 120 °C under vacuum, this process ensures the complete removal of residual solvents like N-Methyl-2-pyrrolidone (NMP). Crucially, it also initiates the molecular alignment of organic components, laying the necessary groundwork for the material's crystallinity in subsequent processing stages.

While the immediate goal is the evaporation of solvents, the vacuum environment is critical for lowering boiling points to achieve "deep drying" without thermal damage. This ensures the electrode achieves necessary molecular alignment and structural stability rather than just surface dryness.

The Science of Solvent Removal

Eliminating Residual NMP

The core task of the oven is the total evaporation of the solvent used to create the slurry, typically N-Methyl-2-pyrrolidone (NMP).

Leaving even trace amounts of solvent can compromise the electrochemical performance of the final battery. The vacuum oven utilizes heat (e.g., 120 °C) to drive this solvent out completely.

Initiating Molecular Alignment

Beyond simple drying, the thermal energy combined with the vacuum environment serves a structural purpose.

This process initiates the molecular alignment of organic components within the slurry. This alignment is a critical prerequisite for enhancing the crystallinity of the material in later production stages.

Ensuring Electrode Integrity

Preventing Surface Defects

Drying a slurry at atmospheric pressure often requires higher temperatures, which can cause the surface to "skin over" and crack.

By using a vacuum, the boiling point of the solvent is significantly lowered. This allows for rapid volatilization at manageable temperatures, preventing defects like bubbles, cracking, or uneven surface layers.

Optimizing Adhesion

The drying process dictates how well the active material binds to the current collector (the copper foil).

A controlled vacuum drying process ensures a uniform distribution of the binder. This significantly enhances the adhesion between the coating and the foil, ensuring the mechanical stability required for the electrode to function.

Understanding the Trade-offs

Temperature Balance

While the primary goal is drying, there is a strict limit to the thermal load the materials can handle.

Operating at 120 °C is effective for NMP removal and crystallinity, but excessive heat can lead to the oxidative degradation of sensitive nanoparticles. The temperature must be high enough to align molecules but low enough to preserve phase purity.

Speed vs. Quality

The vacuum environment accelerates evaporation, but "too fast" can be detrimental.

If the solvent volatilizes too violently due to extreme negative pressure, it may disrupt the coating's uniformity. The process requires a balance of heat and pressure to ensure the slurry dries evenly from the inside out, rather than just flash-drying the surface.

Making the Right Choice for Your Goal

To optimize your composite anode preparation, align your drying parameters with your specific material needs:

- If your primary focus is Crystallinity and Structure: Prioritize a protocol around 120 °C to ensure proper molecular alignment of organic components.

- If your primary focus is Mechanical Stability: Ensure the vacuum level is adjusted to prevent rapid boiling, which secures better adhesion to the copper foil and prevents cracking.

A precisely controlled vacuum drying phase is the difference between a simple coated foil and a high-performance, structurally sound electrode.

Summary Table:

| Feature | Function in Slurry Preparation | Benefit to Electrode Quality |

|---|---|---|

| Solvent Removal | Complete evaporation of NMP at 120°C | Prevents electrochemical performance degradation |

| Vacuum Environment | Lowers solvent boiling point | Prevents surface cracking and bubble formation |

| Thermal Energy | Initiates molecular alignment | Prerequisite for material crystallinity |

| Controlled Drying | Uniform binder distribution | Enhances adhesion between coating and copper foil |

Elevate Your Battery Research with KINTEK Precision

Achieve perfect molecular alignment and structural stability in your composite anodes. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum drying ovens, muffle systems, and CVD solutions tailored for advanced battery material processing. Whether you need customizable temperature profiles or precise vacuum control, our systems ensure your electrodes meet the highest standards of adhesion and crystallinity.

Ready to optimize your lab's thermal processing? Contact us today to find your custom solution!

Visual Guide

References

- Hyeongju Cha, Seok Ju Kang. Curved Nanographene–Graphite Hybrid Anodes with Sequential Li<sup>+</sup> Insertion for Fast‐Charging and Long‐Life Li‐Ion Batteries. DOI: 10.1002/adfm.202514795

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a forced-air drying oven necessary for impregnated kaolin catalysts? Achieve Uniform Component Immobilization

- Why is precise alloy composition adjustment necessary during the preparation of high-performance Cr-Mo-V die steels?

- What is the function of ball milling in Li-NASICON synthesis? Optimize Your Solid Electrolyte Performance

- What gas is used in a graphite furnace? A Guide to Argon vs. Nitrogen for Optimal Analysis

- How does a precision drying oven influence ZnO gel drying? Achieve Perfect Microporous Structures

- What is Joule Heating and how does it relate to induction heating? Master the Physics of Contactless Heating

- How does the temperature capability of continuous furnaces benefit industrial processes? Boost High-Volume Production with Extreme Heat

- How does a temperature-programmed system influence molybdenum carbide formation? Expert Catalyst Synthesis Guide