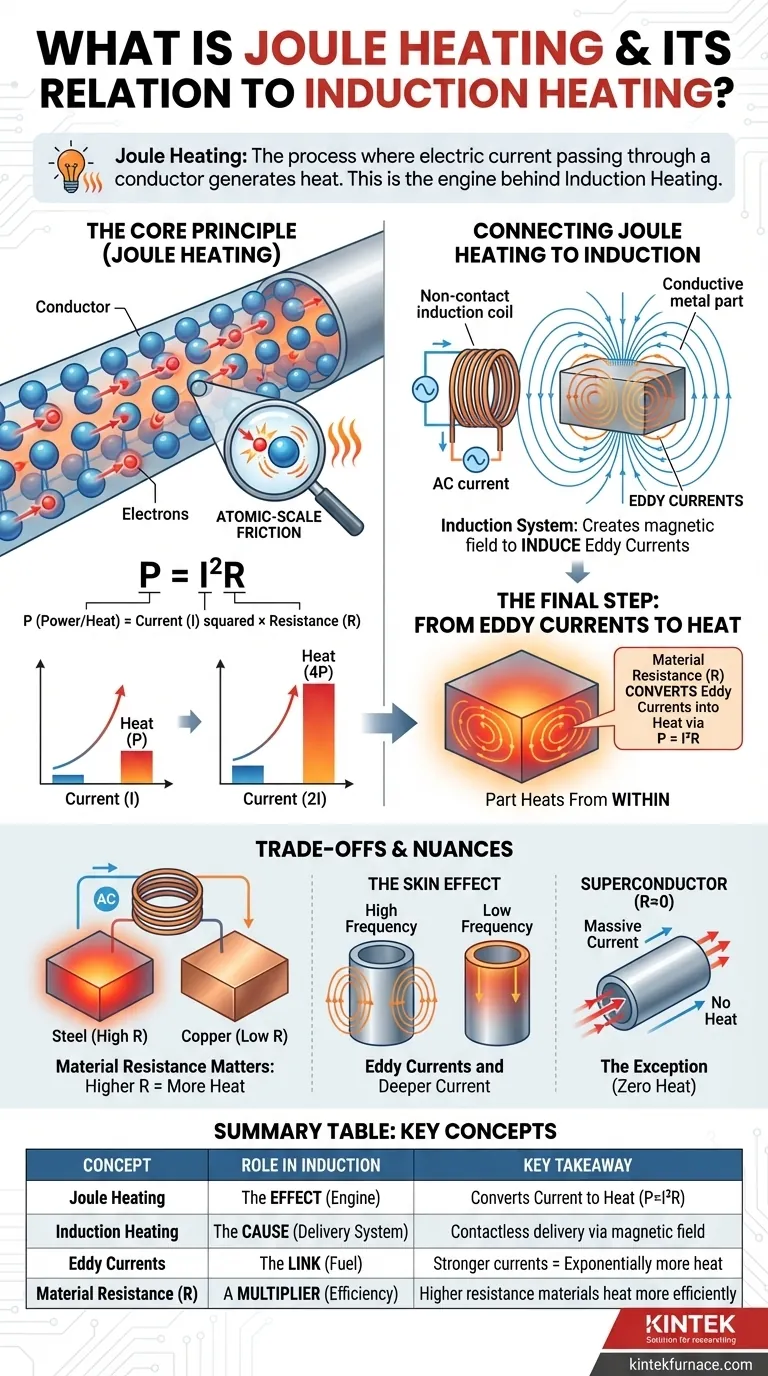

In short, Joule heating is the process by which an electric current passing through a conductor generates heat. This is the fundamental mechanism that makes induction heating work. An induction system uses a magnetic field to create electric currents within a target material, and it is these currents—resisted by the material itself—that generate the heat through the Joule effect.

Induction heating is the cause, and Joule heating is the effect. The induction process creates the necessary electrical currents inside the material, and Joule heating is the physical principle that converts the energy of those currents into useful heat.

Deconstructing Joule Heating: The "Friction" of Electricity

To understand induction, you must first understand the core heating mechanism. Joule heating is a simple, direct relationship between electricity and heat.

The Core Principle

Joule heating, also known as resistive or ohmic heating, is described by Joule's first law. It states that the power of heating (P) generated by an electrical current (I) flowing through a conductor with resistance (R) is P = I²R.

This formula reveals the two critical factors: the amount of current flowing and the material's inherent resistance to that flow.

An Atomic-Level Analogy

Think of Joule heating as a form of atomic-scale friction. As electrons (the electric current) are forced to move through the conductor's atomic lattice, they collide with the atoms.

Each collision transfers kinetic energy from the electron to the atom, causing the atom to vibrate more intensely. This increased atomic vibration is what we perceive and measure as heat.

The Critical Role of Current

The most important variable in the Joule heating formula is the current (I), because its value is squared.

This means doubling the current quadruples the heat output, while tripling it results in nine times the heat. This exponential relationship is key to the rapid heating seen in induction applications.

Connecting Joule Heating to Induction

Induction heating is simply a clever, non-contact method for producing the currents necessary for Joule heating to occur directly within a part.

Induction: Creating Current Without Contact

An induction heating system uses a coil with an alternating current (AC) flowing through it. This creates a rapidly changing magnetic field around the coil.

When a conductive material (like a metal part) is placed within this field, the magnetic field induces circular electrical currents inside the part itself.

Meet the Eddy Currents

These induced, localized currents are known as eddy currents. They are the crucial link between the external magnetic field and the internal heating of the part.

The induction system's job is not to heat the part directly, but to generate the strongest possible eddy currents within it.

The Final Step: From Eddy Currents to Heat

Once these eddy currents are flowing inside the material, they are subject to the material's own electrical resistance.

This is where Joule heating takes over. The resistance of the material impedes the flow of the eddy currents, converting their electrical energy directly into thermal energy according to the P = I²R formula. The part heats up from within, without any external flame or element.

Understanding the Trade-offs and Nuances

While the principle is straightforward, its application involves important considerations that affect efficiency and control.

Why Material Resistance Matters

The resistance (R) in the Joule heating formula is a property of the material being heated. Materials with higher electrical resistance will generate more heat for the same amount of induced eddy current.

This explains why different metals, such as steel versus copper, heat at vastly different rates under the same induction field.

Where the Heating Occurs

The eddy currents, and therefore the Joule heating, are not always distributed evenly. At higher AC frequencies, the currents tend to concentrate near the surface of the material—a phenomenon known as the skin effect.

Engineers use this to their advantage to control the heating depth, whether for surface hardening or for through-heating of an entire billet.

The Exception That Proves the Rule

The concept of Joule heating is reinforced by the existence of superconductors. These materials have virtually zero electrical resistance.

Because their resistance (R) is zero, they can carry massive electrical currents without generating any heat from the Joule effect. This highlights how essential resistance is to the entire heating process.

Applying This to Your Goal

Understanding this relationship allows you to diagnose processes and make more informed decisions. Focus on which part of the equation you need to influence.

- If your primary focus is process efficiency: The key is maximizing the induced eddy currents (

I), because the heating power increases with the square of the current. - If your primary focus is controlling heat location: Understand that induction creates the currents, but Joule heating occurs wherever those currents flow, which can be precisely managed with frequency and coil design.

- If your primary focus is material selection: Remember that the material's own electrical resistance (

R) is a critical factor in how effectively it will convert an induced current into heat.

By understanding that induction is the delivery system and Joule heating is the engine, you gain precise control over the entire thermal process.

Summary Table:

| Concept | Role in Induction Heating | Key Takeaway |

|---|---|---|

| Joule Heating | The effect: Converts electrical current into heat within a material (P = I²R). | The fundamental heating mechanism. |

| Induction Heating | The cause: Uses a magnetic field to create eddy currents inside a material. | The non-contact delivery system for the current. |

| Eddy Currents | The link: Localized currents induced by the magnetic field. | The stronger the current, the greater the heat (exponentially). |

| Material Resistance (R) | A multiplier: The material's inherent property that generates heat from current flow. | Higher resistance materials heat more efficiently. |

Ready to Harness the Power of Contactless Heating?

Understanding the core physics of Joule and induction heating is the first step toward revolutionizing your thermal processes. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to transform this principle into robust, high-performance solutions.

Our advanced product line—including high-temperature Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is engineered to deliver precise, efficient, and repeatable results. Whether you require surface hardening, brazing, melting, or advanced materials synthesis, our strong deep customization capability ensures your furnace or system is tailored to meet your unique experimental and production requirements perfectly.

Let's discuss how we can build a solution that puts you in complete control of your thermal process. Contact our experts today for a consultation.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability