Precise alloy composition adjustment is fundamental to controlling the microstructural integrity of high-performance Cr-Mo-V die steels. It is strictly necessary to modify the type and distribution of carbides, specifically by increasing molybdenum and vanadium content to foster thermally stable MC-type carbides. This process eliminates coarse chromium-based carbides, significantly enhancing the material's resistance to thermomechanical fatigue.

The central goal of composition adjustment is to replace large, unstable chromium carbides with fine, thermally stable MC-type carbides. This microstructural refinement is the single most effective way to extend the material's service life under thermomechanical stress.

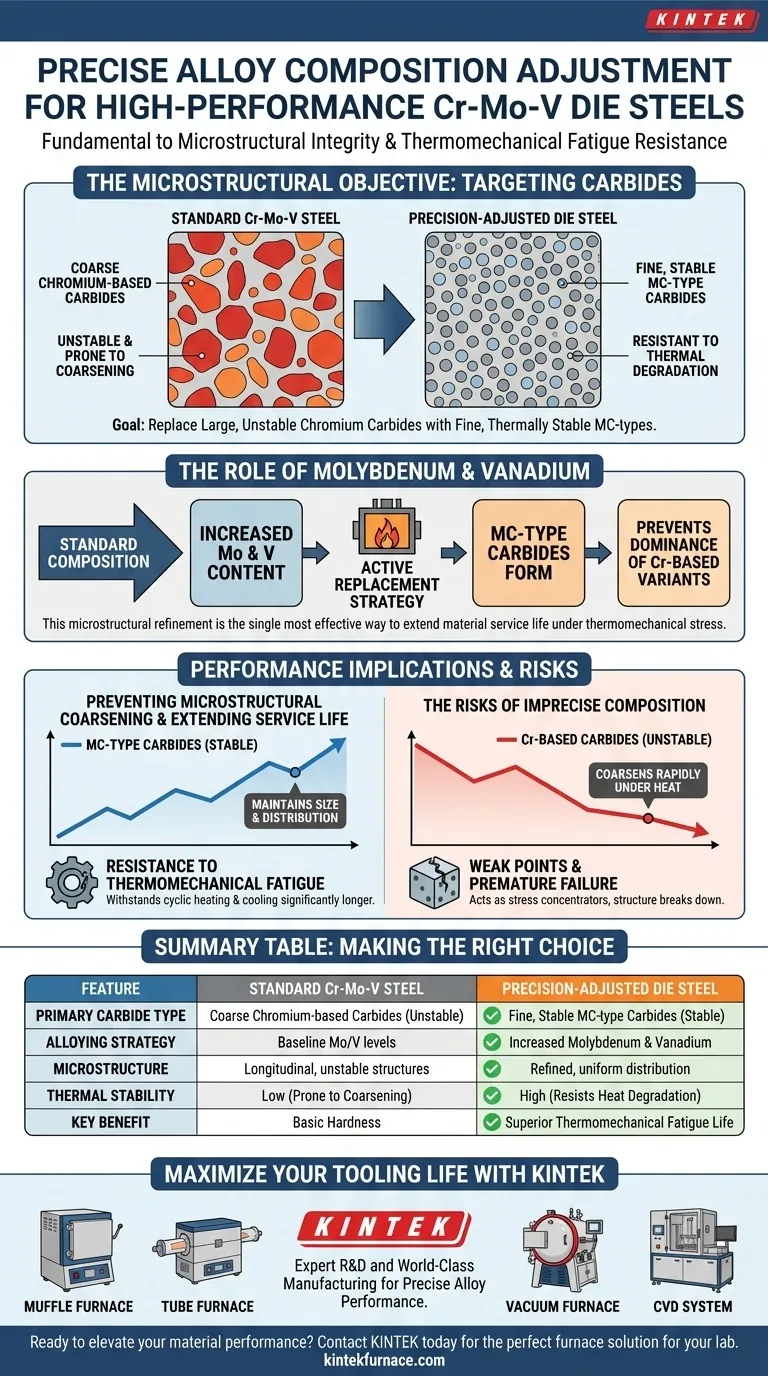

The Microstructural Objective

To understand the necessity of this process, one must look beyond the elemental list and examine how these elements interact at a microscopic level.

Targeting Carbide Types

The primary objective of adjusting the alloy composition is to fundamentally alter the carbide precipitation. Standard die steels often contain chromium-based longitudinal carbides.

These chromium structures are detrimental because they are coarse and unstable. Precision adjustment is required to shift the balance away from these structures and toward more desirable formations.

The Role of Molybdenum and Vanadium

The mechanism for this shift lies in the accurate increase of specific alloying elements. By boosting the content of molybdenum and vanadium, metallurgists force the steel to form MC-type carbides.

This is not a passive change; it is an active replacement strategy. The presence of adequate Molybdenum and Vanadium prevents the dominance of the chromium-based variants.

Performance Implications

The reason for chasing this specific microstructure is directly tied to the operational lifespan of the tool.

Preventing Microstructural Coarsening

Chromium-based carbides are prone to coarsening over time, especially under heat. When carbides grow large and coarse, the material loses toughness and homogeneity.

In contrast, MC-type carbides are thermally stable. They maintain their size and distribution even under the high temperatures inherent in die casting and forging operations.

Extending Service Life

The ultimate output of this chemical precision is resistance to thermomechanical fatigue.

Die steels are subjected to cyclic heating and cooling, which creates immense stress. By replacing unstable carbides with stable MC-types, the material can withstand these cycles significantly longer without degrading.

The Risks of Imprecise Composition

While the benefits of adjustment are clear, failing to achieve the precise balance creates specific vulnerabilities.

The Persistence of Weak Points

If the molybdenum and vanadium levels are not adjusted high enough, the formation of MC-type carbides will be insufficient.

This leaves the coarse chromium-based longitudinal carbides in place. These structures act as stress concentrators and weak points within the steel matrix.

Vulnerability to Thermal Environment

Without the thermal stability provided by MC-carbides, the steel remains prone to rapid degradation.

In a thermomechanical fatigue environment, a lack of precision leads to premature tool failure as the unstable carbides coarsen and the material structure breaks down.

Making the Right Choice for Your Goal

When selecting or specifying high-performance die steels, your focus should be on the intended operating environment and the required longevity of the tool.

- If your primary focus is Maximum Fatigue Life: Ensure the alloy composition has been optimized with elevated Molybdenum and Vanadium levels to maximize MC-type carbide formation.

- If your primary focus is Microstructural Stability: Verify that the processing method explicitly targets the reduction of coarse chromium-based longitudinal carbides.

True performance in die steels is not just about hardness; it is about the thermal stability of the carbide network.

Summary Table:

| Feature | Standard Cr-Mo-V Steel | Precision-Adjusted Die Steel |

|---|---|---|

| Primary Carbide Type | Coarse Chromium-based Carbides | Fine, Stable MC-type Carbides |

| Alloying Strategy | Baseline Mo/V levels | Increased Molybdenum & Vanadium |

| Microstructure | Longitudinal, unstable structures | Refined, uniform distribution |

| Thermal Stability | Low (prone to coarsening) | High (resists heat degradation) |

| Key Benefit | Basic hardness | Superior Thermomechanical Fatigue Life |

Maximize Your Tooling Life with KINTEK

Precise alloy performance requires exact thermal processing. At KINTEK, we understand that achieving the perfect MC-type carbide distribution in Cr-Mo-V die steels depends on superior temperature control and vacuum integrity.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are refining high-performance die steels or developing specialized alloys, our lab high-temp furnaces are fully customizable to meet your unique metallurgical needs.

Ready to elevate your material performance? Contact KINTEK today to consult with our experts on the perfect furnace solution for your lab.

Visual Guide

References

- Yasha Yuan, Jingpei Xie. Strain-Controlled Thermal–Mechanical Fatigue Behavior and Microstructural Evolution Mechanism of the Novel Cr-Mo-V Hot-Work Die Steel. DOI: 10.3390/ma18020334

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What are the advantages of using a vacuum drying oven for ZIF67/MXene? Protect Your Composite Integrity

- What is the design logic behind the double-layer reactor structure used in the ITSP process? Optimize Your Fuel Quality

- Why is a high-temperature sintering furnace critical for BCZT ceramics? Achieving High Densification and Performance

- Why is a high flow rate of synthetic air maintained during magnetite oxidation? Ensure Accurate Kinetic Modeling

- What are the primary advantages of industrial microwave heating equipment? Enhanced Uranium Recovery Through Innovation

- How does a laboratory furnace work? Master the Heating Mechanisms for Your Lab

- What is the function of a constant temperature drying oven in Cr/NiONP synthesis? Ensure Precision and Particle Stability

- What is the main purpose of annealing? A Guide to Controlling Material Properties