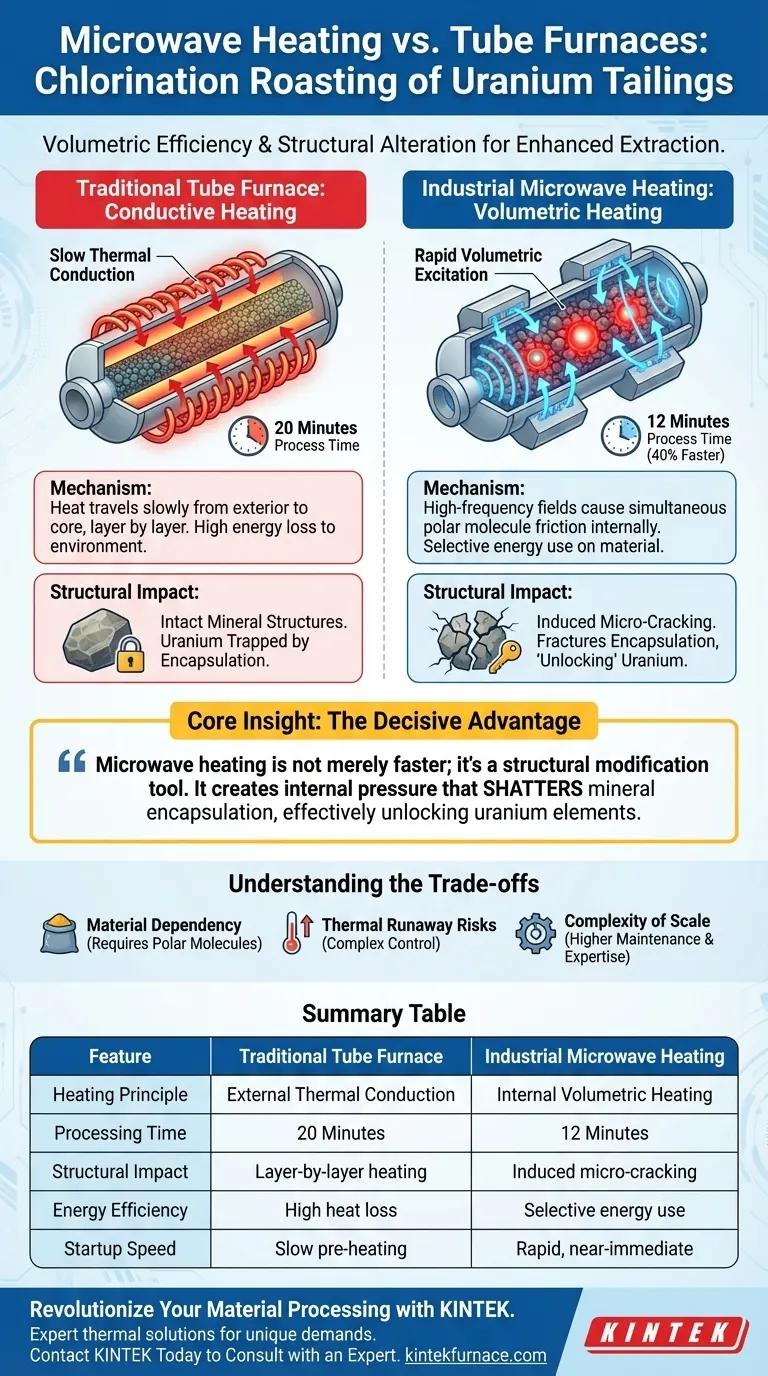

Industrial microwave heating fundamentally transforms the roasting process through volumetric energy transfer. Unlike traditional tube furnaces that rely on slow, layer-by-layer thermal conduction, microwave equipment directly excites polar molecules within the uranium tailings. This mechanism reduces heating time from 20 minutes to just 12 minutes while generating internal thermal stress that physically fractures mineral structures to expose the uranium.

Core Insight: The decisive advantage of microwave heating is not just speed, but structural alteration. By generating heat from within, it creates internal pressure that shatters mineral encapsulation, effectively "unlocking" uranium elements that traditional external heating would leave trapped.

The Mechanism of Efficiency

Volumetric vs. Conductive Heating

Traditional tube furnaces operate on a principle of conduction. Heat must travel slowly from the exterior of the material to the core, layer by layer.

Industrial microwave systems utilize volumetric heating. High-frequency electromagnetic fields penetrate the material, causing high-speed friction among polar molecules throughout the entire volume simultaneously.

Selective Energy Application

Microwaves do not heat the air or the container first; they act directly on the microwave-absorbing phases within the tailings. This ensures that energy is expended exactly where it is needed—on the mineral itself—rather than being wasted on the surrounding environment.

Breaking the Mineral Barrier

Creating Thermal Stress

Because microwave heating generates heat in-situ (inside the material), the internal temperature often rises faster than the surface temperature. This creates a significant temperature gradient between the core and the exterior of the particle.

Induced Micro-Cracking

This thermal gradient generates intense thermal stress within the tailings. The stress eventually exceeds the material's strength, causing micro-cracks to form throughout the mineral structure.

Exposing the Target Element

These micro-cracks are critical for the extraction process. They break down the physical mineral encapsulation structures that typically shield uranium. By fracturing these barriers, the microwave process opens pathways for subsequent acid leaching to reach and dissolve the uranium more effectively.

Operational Speed and Throughput

Drastic Reduction in Processing Time

The lag time inherent in conductive heating is eliminated. According to the data, switching to microwave heating reduces the roasting duration from 20 minutes down to 12 minutes.

Immediate Start-up

Traditional furnaces often require long pre-heating cycles to reach stable temperatures. Microwave systems offer rapid temperature rise, allowing the system to reach operational efficiency almost immediately.

Understanding the Trade-offs

Material Dependency

Microwave heating is highly dependent on the dielectric properties of the material. If the uranium tailings contain few polar molecules or lack microwave-absorbing phases, the efficiency gains described above will be significantly diminished or non-existent.

Thermal Runaway Risks

Because heating occurs internally and rapidly, control is more complex than in traditional furnaces. Without precise monitoring, "hot spots" can form where temperatures spike uncontrollably, potentially altering the chemical composition beyond the desired roasting parameters.

Complexity of Scale

While a tube furnace is mechanically simple, industrial microwave equipment involves complex magnetrons and waveguides. This requires a higher level of technical maintenance and operator expertise to ensure consistent performance.

Making the Right Choice for Your Goal

To decide if transitioning to industrial microwave heating is the right engineering move for your facility, consider your primary constraints:

- If your primary focus is Increasing Throughput: The 40% reduction in heating time (20 min to 12 min) offers a direct path to higher volume processing without increasing the facility footprint.

- If your primary focus is Extraction Yield: The creation of micro-cracks and the breakdown of encapsulation structures will likely provide higher recovery rates during the leaching phase.

- If your primary focus is Operational Simplicity: Traditional tube furnaces remain a robust, lower-maintenance option for materials that do not require structural fracturing to release the uranium.

Microwave heating is not merely a faster furnace; it is a structural modification tool that prepares the ore for maximum extraction efficiency.

Summary Table:

| Feature | Traditional Tube Furnace | Industrial Microwave Heating |

|---|---|---|

| Heating Principle | External Thermal Conduction | Internal Volumetric Heating |

| Processing Time | 20 Minutes | 12 Minutes (40% faster) |

| Structural Impact | Layer-by-layer heating | Induced micro-cracking & fracturing |

| Energy Efficiency | High heat loss to environment | Selective energy use on material |

| Startup Speed | Slow pre-heating cycles | Rapid, near-immediate startup |

Revolutionize Your Material Processing with KINTEK

Is your lab or facility ready to transition from slow conductive heating to high-efficiency volumetric systems? KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing.

Our extensive range includes Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the unique dielectric and structural demands of your specific materials. Whether you are aiming to increase throughput or improve extraction yields in specialized mineral processing, our team is ready to design the perfect high-temp furnace for your needs.

Contact KINTEK Today to Consult with an Expert

Visual Guide

References

- Jinming Hu, Fangdong Zou. Low-Temperature Chlorination-Roasting–Acid-Leaching Uranium Process of Uranium Tailings: Comparison Between Microwave Roasting and Conventional Roasting. DOI: 10.3390/pr13010082

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the technical purpose of the ball milling process for Ti12%Zr? Master Mechanical Activation & Alloying

- How does a high-precision temperature-controlled annealing furnace influence packaging steel microstructure?

- What PPE is suggested for adjusting controls or handling equipment during furnace operation? Essential Gear for Operator Safety

- What are the advantages of HDH niobium powder in Ti-Nb alloys? Optimize Costs and Microstructure

- Why is precise temperature control below 1700°C required for beta-SiC? Master Your Cubic Silicon Carbide Synthesis

- What is the role of a laboratory drying oven in catalyst precursor control? Maximize Dispersion and Stability

- How does the structure of a shaft furnace facilitate the reduction of iron ore? Mastering High-Temp Heat Exchange

- What role does precision analytical equipment play in petrochemical R&D? Engineering the Future of Efficient Refining