To safely adjust controls or handle equipment during furnace operation, you must wear a specific set of personal protective equipment (PPE). The minimum required gear includes high-quality heat-resistant gloves, safety glasses or goggles, and appropriate protective clothing. This equipment is your direct shield against the primary hazards of intense heat and potential splashes of molten material.

While PPE is the essential last line of defense for the operator, true furnace safety is achieved through a comprehensive system that minimizes hazards at their source, integrating equipment integrity with disciplined operational procedures.

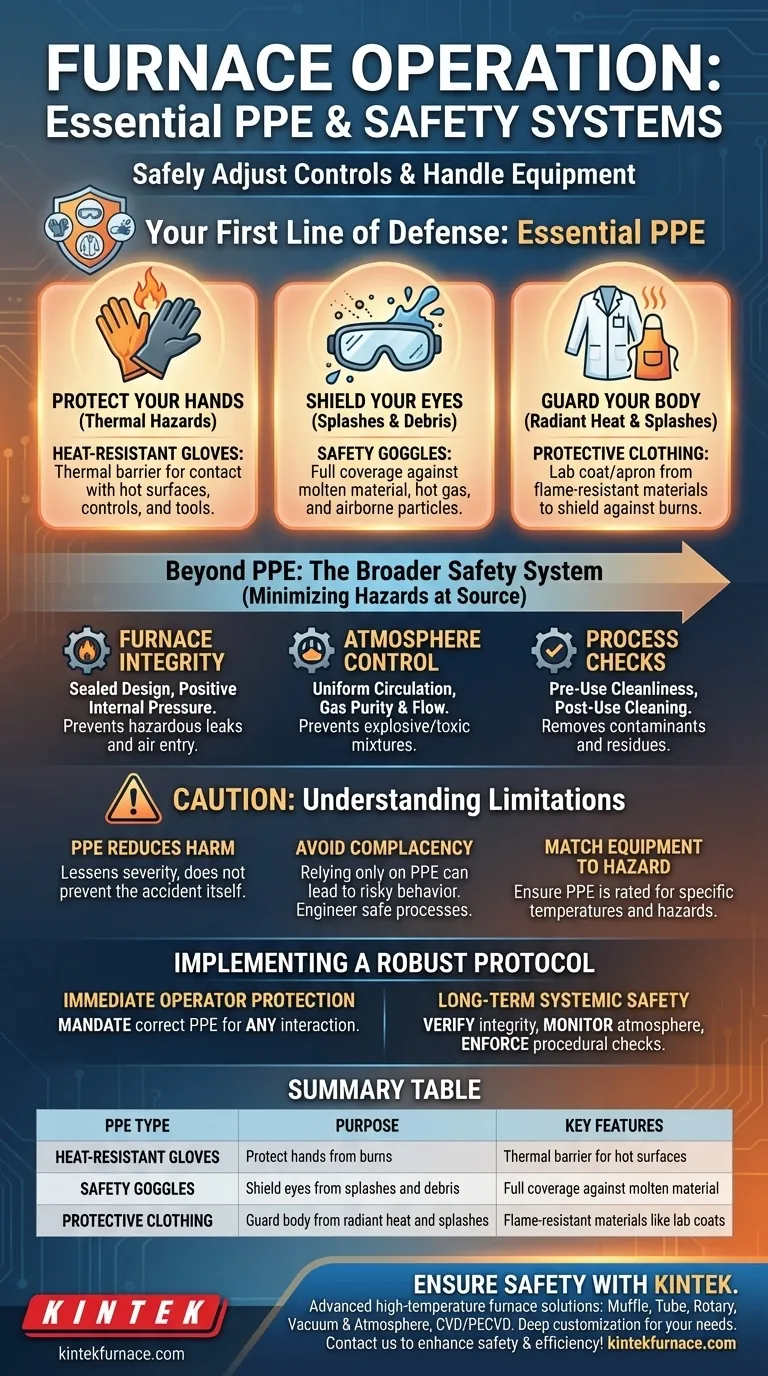

Your First Line of Defense: Essential PPE

When interacting with a live furnace, you are exposed to significant thermal and chemical risks. The following PPE is non-negotiable for protecting yourself from immediate harm.

Protecting Your Hands from Thermal Hazards

Heat-resistant gloves are critical for any task involving potential contact with hot surfaces or equipment. They provide a thermal barrier, protecting your hands from burns when adjusting controls, handling tools, or moving materials near the furnace.

Shielding Your Eyes from Splashes and Debris

Safety glasses, or preferably goggles for fuller coverage, protect your eyes from multiple hazards. They are essential for guarding against splashes of molten material, sudden bursts of hot gas, and airborne particulate matter that can be ejected during operation.

Guarding Your Body with Protective Clothing

Protective clothing, such as a lab coat or apron made from heat- and flame-resistant materials, shields your body from radiant heat. It also provides a critical layer of protection against accidental contact with hot surfaces or splashes that could cause severe burns.

Beyond PPE: The Broader Safety System

Relying on PPE alone is insufficient. A robust safety protocol treats PPE as the final safeguard, supported by a system designed to prevent incidents from happening in the first place.

The Importance of Furnace Integrity

A properly maintained furnace is inherently safer. A sealed furnace design with positive internal pressure is a critical feature, as it prevents hazardous gas leaks and stops outside air from entering, which could cause an uncontrolled reaction.

The Role of Atmosphere Control

Safety depends on maintaining a stable and predictable environment inside the furnace. This requires uniform atmosphere circulation and continuous verification of gas purity and flow rates to prevent the formation of explosive or toxic mixtures.

Discipline Through Process Checks

Safety is a continuous process, not a one-time setup. Pre-use cleanliness checks ensure no contaminants are present that could react at high temperatures. Likewise, post-use cleaning removes residues, ensuring the furnace is in a safe state for its next operation.

Understanding the Limitations

Even the best PPE has limitations. Recognizing these is key to avoiding complacency and ensuring your safety protocols are truly effective.

PPE Reduces Harm, It Doesn't Eliminate Hazards

PPE is designed to lessen the severity of an injury in the event of an accident. It does not, and cannot, prevent the accident itself. For example, gloves protect from a hot surface, but they don't prevent the surface from being dangerously hot.

The Risk of a False Sense of Security

Relying exclusively on PPE can lead to riskier behavior. The real goal is to engineer a safe process where PPE acts as a final backup, not the primary safety measure. The safest interaction with a hazard is the one you don't have to make.

Match the Equipment to the Specific Hazard

Not all "heat-resistant" equipment is the same. The specific gloves and clothing you use must be rated for the temperatures and specific hazards of your application. Using under-specified PPE can provide inadequate protection and lead to serious injury.

Implementing a Robust Furnace Safety Protocol

Use these principles to build a comprehensive safety strategy for your operations.

- If your primary focus is immediate operator protection: Mandate the use of correctly rated heat-resistant gloves, safety goggles, and protective clothing for any interaction with an operating furnace, no exceptions.

- If your primary focus is long-term systemic safety: Implement a full safety system that includes verifying furnace integrity, continuously monitoring the internal atmosphere, and enforcing strict pre- and post-operation procedural checks.

By combining the right personal equipment with a disciplined and systemic approach to safety, you create a resilient and truly safe working environment.

Summary Table:

| PPE Type | Purpose | Key Features |

|---|---|---|

| Heat-Resistant Gloves | Protect hands from burns | Thermal barrier for hot surfaces |

| Safety Goggles | Shield eyes from splashes and debris | Full coverage against molten material |

| Protective Clothing | Guard body from radiant heat and splashes | Flame-resistant materials like lab coats |

Ensure your laboratory's safety with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to enhance your safety protocols and operational efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production