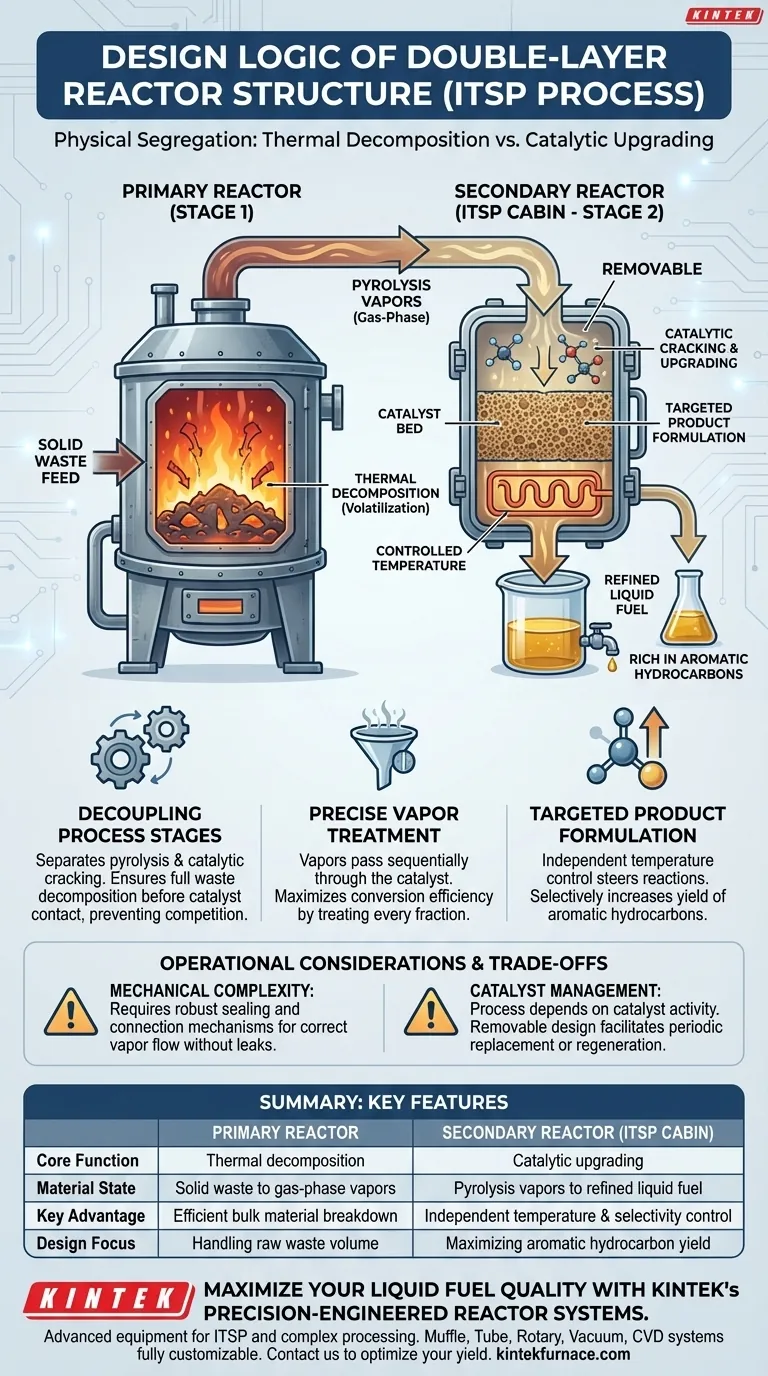

The design logic of the double-layer reactor structure within the Integrated Two-Step Pyrolysis (ITSP) process centers on the physical segregation of thermal decomposition from catalytic upgrading. This architecture employs a primary reactor to break down raw waste and a distinct, removable secondary reactor—known as the ITSP cabin—to refine the resulting vapors.

The core advantage of this split design is the ability to independently optimize the initial breakdown of material and the subsequent chemical refining. By passing pyrolysis vapors through a catalyst-rich secondary chamber at controlled temperatures, the system targets the production of high-quality liquid fuels rich in aromatic hydrocarbons.

The Physical Architecture

The Primary Reactor

The foundation of the system is the primary reactor. Its specific function is to handle the bulk thermal decomposition of the waste material. This vessel creates the necessary environment to volatilize solid waste into gas-phase pyrolysis vapors.

The Removable Secondary Reactor (ITSP Cabin)

Situated downstream or distinct from the primary vessel is the secondary reactor, often referred to as the ITSP cabin. This component is designed to be removable, which facilitates maintenance and catalyst loading. It serves as the dedicated housing for the catalytic agents required for the second stage of the process.

Functional Advantages of Separation

Decoupling Process Stages

The double-layer structure allows for the clear separation of pyrolysis (breaking down) and catalytic cracking (upgrading). In a single-stage reactor, these processes often compete or interfere with one another. By separating them physically, the ITSP process ensures that the waste is fully decomposed before it ever encounters the catalyst.

Precise Vapor Treatment

The design forces pyrolysis vapors generated in the primary reactor to pass through the secondary reactor. As these vapors flow through the catalyst bed, they undergo catalytic cracking. This sequential flow ensures that every fraction of the vapor is treated, maximizing the conversion efficiency.

Targeted Product Formulation

Because the secondary reactor operates as a distinct unit, it can maintain controlled temperatures independent of the primary reactor. This thermal precision is critical for selectivity. It steers the chemical reactions toward the formation of specific high-value compounds, specifically increasing the yield of aromatic hydrocarbons in the final liquid fuel.

Operational Considerations and Trade-offs

Mechanical Complexity

While efficient, a double-layer system introduces more mechanical complexity than a simple single-pot reactor. The design requires robust sealing and connection mechanisms to ensure vapors flow correctly from the primary to the secondary reactor without leaking.

Catalyst Management

The reliance on a secondary reactor means the process is heavily dependent on catalyst activity. The "removable" nature of the ITSP cabin suggests that the catalyst will eventually deactivate and require physical replacement or regeneration, introducing a necessary maintenance interval that must be planned for.

Making the Right Choice for Your Goal

To determine if the ITSP double-layer structure aligns with your processing goals, consider your desired end-product.

- If your primary focus is fuel quality: This design is ideal, as the secondary catalytic step is specifically engineered to produce high-quality liquid fuels with high aromatic content.

- If your primary focus is process simplicity: You must weigh the benefits of higher fuel quality against the added operational requirement of managing a two-stage, catalyst-dependent system.

The ITSP double-layer structure effectively sacrifices mechanical simplicity to achieve superior chemical precision and higher-value fuel outputs.

Summary Table:

| Feature | Primary Reactor | Secondary Reactor (ITSP Cabin) |

|---|---|---|

| Core Function | Thermal decomposition (volatilization) | Catalytic upgrading (cracking) |

| Material State | Solid waste to gas-phase vapors | Pyrolysis vapors to refined liquid fuel |

| Key Advantage | Efficient bulk material breakdown | Independent temperature & selectivity control |

| Design Focus | Handling raw waste volume | Maximizing aromatic hydrocarbon yield |

Maximize Your Liquid Fuel Quality with KINTEK

Take your thermal processing to the next level with KINTEK’s precision-engineered reactor systems. Whether you are implementing Integrated Two-Step Pyrolysis (ITSP) or complex catalytic cracking, our advanced equipment is designed to handle the mechanical demands of multi-stage processing.

Backed by expert R&D and world-class manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temp furnaces—all fully customizable to meet your unique laboratory or industrial requirements.

Ready to optimize your fuel yield and chemical precision? Contact us today to discuss how our custom furnace solutions can empower your research and production.

Visual Guide

References

- Indra Mamad Gandidi, Arinal Hamni. Integrated two-step co-pyrolysis under several low-cost natural catalysts to produce aromatic-rich liquid fuel from mixed municipal solid waste. DOI: 10.1093/ce/zkae092

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a glove box provide environmental control for Mn2AlB2 precursors? Protect Material Purity & Reaction Accuracy

- Why is a rapid cooling process necessary for BZSM nanophosphors? Secrets of Metastable Phase Retention

- How does Oxygen-Enhanced Combustion (OEC) improve furnace thermal efficiency? Boost Energy Savings and Heat Recovery

- What are the functions of a rotary evaporator and a vacuum drying oven in LTO sol-gel? Optimize Your Synthesis Process

- What are the advantages of Spark Plasma Sintering (SPS)? Enhance Thermoelectric Performance in Copper Sulfide

- How is a CCD camera used for iron ore pellet deformation? Master Non-Contact Strain Measurement at High Temperatures

- What role does a high-power graphite resistance furnace play in SiC ceramic treatment? Achieve Perfect Crystallization

- Why is it necessary for sintering equipment to have a high-cooling-rate control for 17-4 PH? Master Your Metallurgy