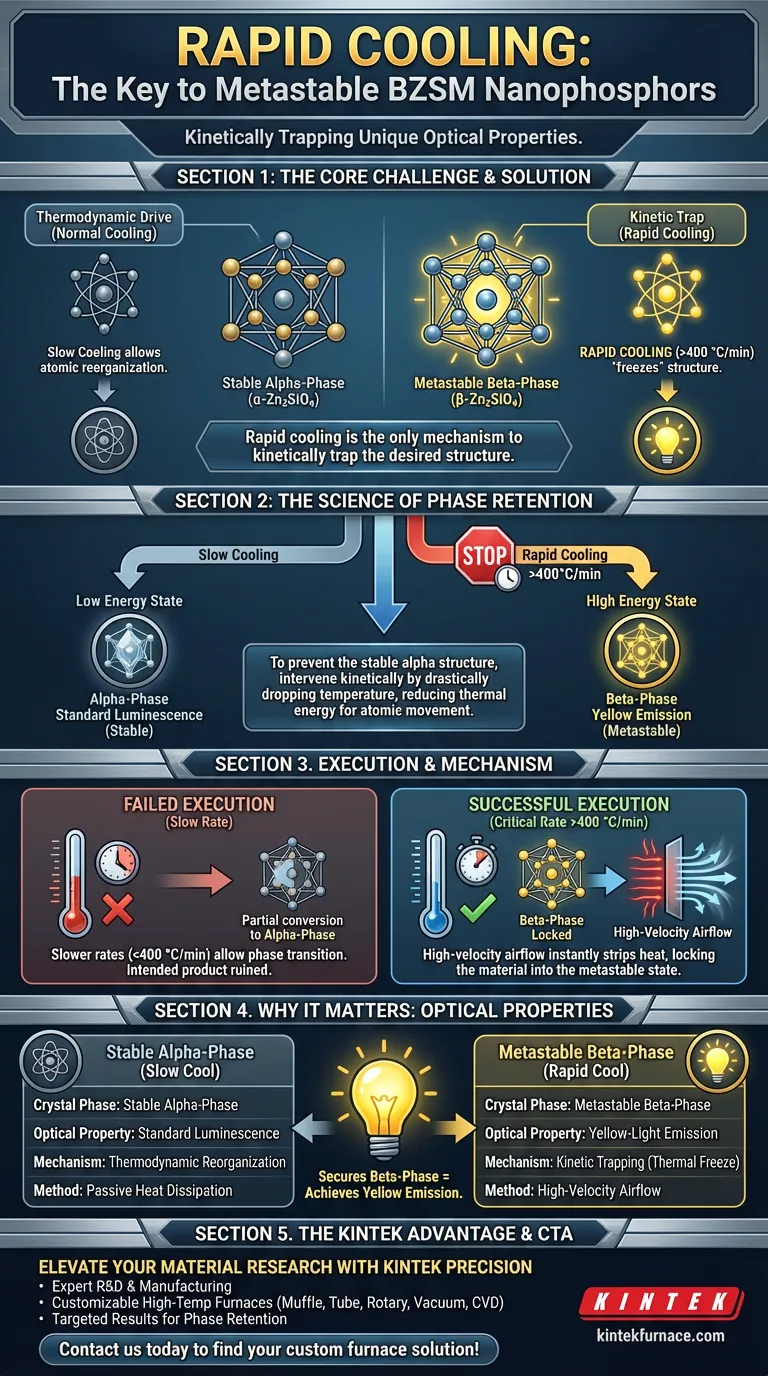

Rapid cooling is the only mechanism capable of kinetically trapping the desired metastable structure before it reverts to a stable state. Specifically, cooling rates exceeding 400 °C/min are strictly necessary to suppress the natural transformation from the high-temperature beta-phase to the thermodynamically stable alpha-phase, effectively "freezing" the yellow-emitting BZSM structure at room temperature.

Thermodynamic forces naturally drive the material toward the stable alpha-phase as it cools. Rapid cooling overrides this tendency, preserving the unique optical properties of the metastable beta-phase by denying the atomic structure the time required to reorganize.

The Science of Phase Retention

Overcoming Thermodynamics

Under normal conditions, materials seek their most stable energy state. For Zn2SiO4, the alpha-phase represents this thermodynamically stable state at room temperature.

The Kinetic "Freeze"

To prevent the material from adopting this stable alpha structure, you must intervene kinetically. By dropping the temperature drastically, you reduce the thermal energy available for atomic movement.

This creates a "kinetic trap." The atoms are essentially frozen in their high-temperature configuration (the beta-phase) because they lack the energy and time to migrate into the alpha-phase arrangement.

Execution and Mechanism

The Critical Rate Threshold

There is no margin for error in the cooling speed. The process requires a cooling rate significantly exceeding 400 °C/min.

Slower rates will fail to outpace the phase transition mechanisms. If the temperature drops too gradually, the material will partially or fully convert to the alpha-phase, ruining the intended product.

Utilizing High-Velocity Airflow

To achieve this aggressive thermal drop, high-velocity airflow is employed. This method strips heat away from the sample instantly.

This rapid heat extraction is the functional mechanism that suppresses the phase transition, locking the material into the metastable state.

Why This Matters: Optical Properties

Securing the Beta-Phase

The entire purpose of this rapid cooling is to obtain metastable beta-Zn2SiO4. This specific crystal structure does not exist naturally at room temperature without this intervention.

Achieving Yellow Emission

The physical structure of the beta-phase dictates its optical output. Successfully retaining this phase results in yellow-light emission.

If the cooling process fails and the material reverts to the alpha-phase, these specific luminescent properties are lost.

Understanding the Trade-offs

Equipment Complexity

Achieving a cooling rate of >400 °C/min requires specialized process control. Standard ambient cooling or passive heat dissipation is insufficient, requiring active high-velocity airflow systems.

Stability vs. Function

By prioritizing the metastable beta-phase, you are creating a material that is, by definition, not in its lowest energy state. While this grants the desired optical properties, it means the material could revert to the alpha-phase if re-heated or subjected to sufficient energy in the future.

Making the Right Choice for Your Goal

- If your primary focus is obtaining yellow light emission: You must enforce a cooling rate greater than 400 °C/min to kinetically trap the beta-phase structure.

- If your primary focus is thermodynamic stability: A slower cooling rate will allow the material to relax into the stable alpha-phase, though you will lose the specific optical characteristics of the BZSM nanophosphors.

Mastering the cooling rate allows you to dictate the material's final crystal structure, turning a transient high-temperature state into a functional room-temperature product.

Summary Table:

| Feature | Rapid Cooling (>400°C/min) | Slow Cooling |\n| :--- | :--- | :--- |\n| Crystal Phase | Metastable Beta-Phase | Stable Alpha-Phase |\n| Optical Property | Yellow-Light Emission | Standard Luminescence |\n| Mechanism | Kinetic Trapping (Thermal Freeze) | Thermodynamic Reorganization |\n| Method | High-Velocity Airflow | Passive Heat Dissipation |

Elevate Your Material Research with KINTEK Precision\n\nAchieving critical cooling rates of 400°C/min requires advanced thermal processing equipment designed for precision and speed. At KINTEK, we specialize in providing high-performance laboratory solutions tailored for complex material synthesis. \n\nWhy partner with KINTEK?\n* Expert R&D & Manufacturing: Our systems are built to handle the rigorous demands of phase-retention studies.\n* Customizable High-Temp Furnaces: Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, we customize our technology to meet your specific cooling and heating profiles.\n* Targeted Results: We help researchers and manufacturers kinetically trap metastable structures and lock in unique material properties.\n\nReady to optimize your nanophosphor production? Contact us today to find your custom furnace solution!

Visual Guide

References

- Mohammad M. Afandi, Jongsu Kim. Bright Yellow Luminescence from Mn2+-Doped Metastable Zinc Silicate Nanophosphor with Facile Preparation and Its Practical Application. DOI: 10.3390/nano14171395

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Spark Plasma Sintering SPS Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of using a laboratory drying oven for catalyst recycling? Optimize Performance & Data Integrity

- Why is carbon dioxide utilized for the in-situ gasification regeneration of NiCuCe catalysts? Enhance Catalyst Longevity

- What is the significance of using a vacuum drying oven? Optimize Supercapacitor Electrode Performance

- How does a batch furnace differ from a continuous furnace? Choose the Right Furnace for Your Production Needs

- Why is it necessary to configure a high-purity nitrogen atmosphere or vacuum system for Al2O3/TiC microwave sintering?

- Why is a laboratory oven used for 80 °C drying before sintering NASICON membranes? Ensure Structural Integrity

- Why is high-temperature homogenization necessary for refractory alloy thermal expansion tests? Ensure Data Precision.

- What role does temperature control play in biomass pyrolysis for biochar? Achieve Optimal Pore Structure & Yield