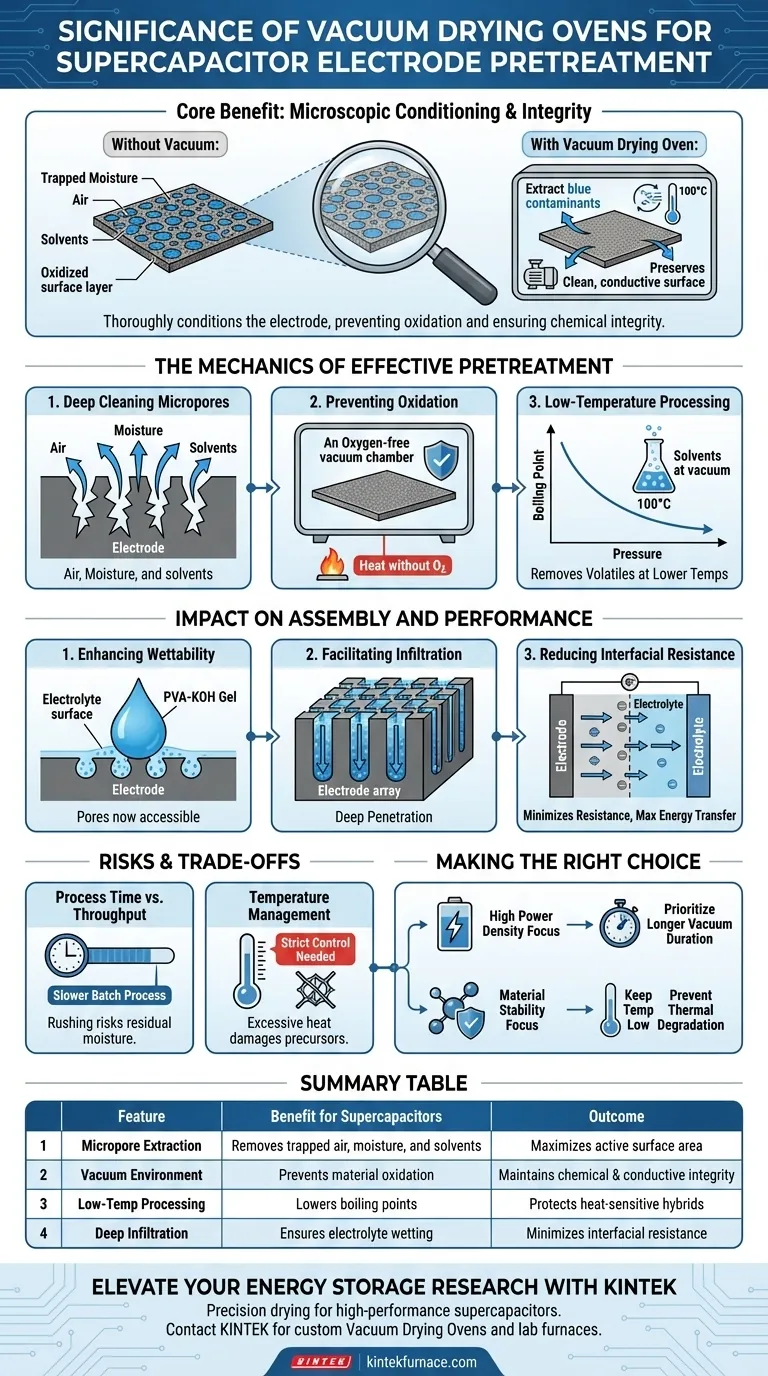

The significance of using a vacuum drying oven lies in its ability to thoroughly condition the electrode at a microscopic level. It functions by extracting air, residual solvents, and moisture deep within the micropores of the electrode sheets under controlled temperatures. Crucially, doing this in a vacuum prevents the oxidation of delicate materials that often occurs during conventional heating, ensuring the material retains its chemical integrity.

By eliminating microscopic barriers and preventing oxidation, vacuum drying ensures the electrolyte can fully penetrate the electrode structure. This deep infiltration is the critical factor in minimizing interfacial resistance and maximizing the energy transfer efficiency of the supercapacitor.

The Mechanics of Effective Pretreatment

Deep Cleaning Micropores

Electrode materials are porous by design to maximize surface area. However, these micropores often trap air, moisture, and solvents left over from manufacturing. A vacuum drying oven creates a pressure differential that physically pulls these contaminants out from the deepest parts of the material structure.

Preventing Oxidation

Standard drying methods rely on heat, which can react with oxygen in the air to degrade the electrode surface. The vacuum environment removes oxygen, allowing you to apply the necessary heat to dry the sheets without triggering oxidation. This preserves the pristine conductive surface required for high performance.

Low-Temperature Processing

The vacuum lowers the boiling point of solvents and water. This means you can remove volatile components at lower temperatures (e.g., 100°C). This is vital for organic-inorganic hybrid materials that might deteriorate or lose their structural integrity under higher heat.

Impact on Assembly and Performance

Enhancing Wettability

For a supercapacitor to function, the electrolyte must touch the active material. If pores are blocked by air or moisture, the electrolyte cannot enter. Vacuum drying ensures the active surfaces are fully accessible, allowing viscous electrolytes—such as PVA-KOH gels—to effectively wet the surface.

Facilitating Infiltration

Beyond simple surface contact, the electrolyte needs to penetrate the electrode arrays. A thoroughly dried and evacuated electrode allows the gel electrolyte to infiltrate the porous structure completely. This maximizes the "double-layer" capacitance effect.

Reducing Interfacial Resistance

The primary enemy of supercapacitor efficiency is resistance at the interface between the electrode and the electrolyte. By ensuring deep infiltration and a clean surface, vacuum drying significantly reduces interfacial resistance. This leads to better power density and more efficient charge/discharge cycles.

Understanding the Risks and Trade-offs

Process Time vs. Throughput

Vacuum drying is inherently slower than continuous air drying because it requires a sealed batch environment to achieve low pressure. Rushing this stage is a common error. If the vacuum duration is too short, residual moisture remains deep in the pores, negating the benefits of the process.

Temperature Management

While vacuum allows for lower temperatures, excessive heat can still damage sensitive precursors. Even in a vacuum, you must strictly control the temperature profile to maintain the desired loose powder structure or sheet integrity. Overheating can collapse the pores you are trying to clean.

Making the Right Choice for Your Project

To maximize the utility of vacuum drying for your specific application, consider the following:

- If your primary focus is High Power Density: Prioritize the duration of the vacuum cycle to ensure absolute dryness, which creates the lowest possible interfacial resistance.

- If your primary focus is Material Stability: Focus on keeping the drying temperature as low as possible (leveraging the vacuum) to prevent the thermal degradation of organic components.

The precision of your drying process directly dictates the accessible surface area and efficiency of your final energy storage device.

Summary Table:

| Feature | Benefit for Supercapacitors | Outcome |

|---|---|---|

| Micropore Extraction | Removes trapped air, moisture, and solvents | Maximizes active surface area |

| Vacuum Environment | Prevents material oxidation at high temperatures | Maintains chemical & conductive integrity |

| Low-Temp Processing | Lowers boiling points of volatile solvents | Protects heat-sensitive organic-inorganic hybrids |

| Deep Infiltration | Ensures electrolytes (e.g., PVA-KOH) wet the structure | Minimizes interfacial resistance |

Elevate Your Energy Storage Research with KINTEK

Precision drying is the foundation of high-performance supercapacitors. At KINTEK, we understand that even microscopic moisture can compromise your energy density. Our advanced Vacuum Drying Ovens are engineered to provide the uniform heating and deep-vacuum environments necessary to preserve delicate electrode materials while ensuring complete electrolyte infiltration.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique material science needs.

Ready to reduce interfacial resistance and maximize your lab's efficiency? Contact us today to find your custom solution!

Visual Guide

References

- Zhiqiang Cui, Rui Tong. Rationally Designed PPy-Coated Fe2O3 Nanoneedles Anchored on N-C Nanoflakes as a High-Performance Anode for Aqueous Supercapacitors. DOI: 10.3390/cryst15040346

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why is high-purity argon gas required during the calcination of TiO2/MoSe2 materials? Protect Your Sensor's Integrity

- What is the graphite furnace technique? A Guide to Ultra-Trace Metal Analysis

- What is the function of a laboratory drying oven in thin film solvent removal? Ensure Defect-Free Solidification

- What is the role of industrial thermometers in monitoring thermal stress? Ensure Safety via High-Precision Data

- What is the primary function of glass matrices in HLW vitrification? Achieve Safe Radioactive Waste Immobilization

- How does a batch furnace differ from a continuous furnace? Choose the Right Furnace for Your Production Needs

- Why is it necessary for sintering equipment to have a high-cooling-rate control for 17-4 PH? Master Your Metallurgy

- What is the purpose of the 0.5 cm tunnel structure in LLZO sintering? Achieve Superior Structural Uniformity