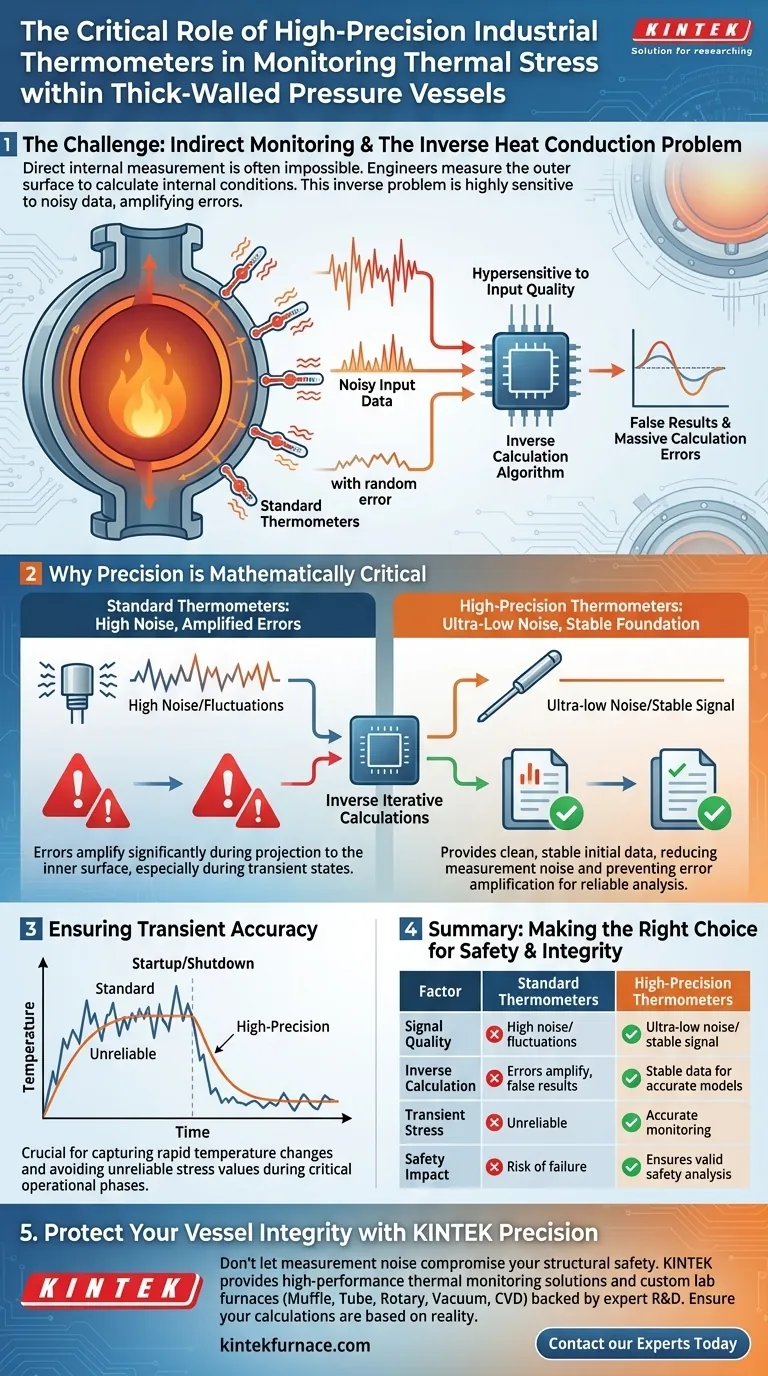

High-precision industrial thermometers function as the critical stabilization mechanism for the complex mathematics used to determine thermal stress in thick-walled pressure vessels. Their role extends beyond simple monitoring; they provide the ultra-low-noise data required to solve inverse heat conduction problems without generating false results.

The mathematical models used to estimate internal stress are hypersensitive to input quality. High-precision hardware is not merely a preference but a mathematical necessity to prevent minor measurement noise from amplifying into massive calculation errors regarding the vessel's inner surface.

The Challenge of Indirect Monitoring

Solving the Inverse Heat Conduction Problem

In thick-walled pressure vessels, directly measuring conditions on the inner surface is often impossible or impractical.

Engineers must measure temperatures on the outer surface and use mathematical algorithms to calculate what is happening inside.

This process is known as the inverse heat conduction problem.

Sensitivity to Input Data

The algorithms used to solve these inverse problems are inherently unstable when dealing with "noisy" data.

They are highly sensitive to random errors found in standard sensor readings.

Even slight fluctuations in the input temperature can lead to disproportionately large inaccuracies in the final analysis.

Why Precision is Mathematically Critical

Reducing Measurement Noise

High-precision industrial thermometers provide initial temperature data with minimal fluctuations.

By delivering a "clean" signal, these thermometers reduce measurement noise that would otherwise confuse the calculation.

This stability is the foundation for any accurate transient thermal stress analysis.

Preventing Error Amplification

The calculation process involves inverse iterative calculations that project data from the outside of the wall toward the inner surface.

During this projection, errors do not remain static; they grow.

Small measurement errors at the source can be significantly amplified by the time the algorithm calculates the inner surface conditions.

Ensuring Transient Accuracy

Thermal stress is often most dangerous during "transient" states—when temperatures are changing rapidly (such as startup or shutdown).

High-precision hardware ensures the accuracy of these calculated transient thermal stresses.

Without this precision, the derived stress values would likely be unreliable and potentially unsafe.

Understanding the Risks

The Reliability Trap

It is a common pitfall to assume that standard thermometers are "close enough" for massive industrial vessels.

However, in the context of inverse calculations, close is not good enough.

A standard thermometer with average noise levels can render the entire stress calculation algorithm useless due to the amplification effect described above.

Making the Right Choice for Your Goal

When selecting instrumentation for pressure vessels, your choice dictates the validity of your structural analysis.

- If your primary focus is safety and structural integrity: Prioritize thermometers with the lowest possible signal-to-noise ratio to ensure inverse calculations reflect reality, not sensor error.

- If your primary focus is system design: Ensure your data acquisition hardware matches the precision of your sensors to avoid introducing noise after the measurement is taken.

The accuracy of your stress analysis is defined not by your math, but by the stability of your initial temperature measurement.

Summary Table:

| Factor | Standard Thermometers | High-Precision Thermometers |

|---|---|---|

| Signal Quality | High noise and fluctuations | Ultra-low noise, stable signal |

| Inverse Calculation | Errors amplify, causing false results | Provides stable data for accurate models |

| Transient Stress | Unreliable during rapid changes | Accurate monitoring during startup/shutdown |

| Safety Impact | Risk of structural integrity failure | Ensures valid, data-driven safety analysis |

Protect Your Vessel Integrity with KINTEK Precision

Don't let measurement noise compromise your structural safety. KINTEK provides high-performance thermal monitoring solutions designed for the most demanding industrial environments. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique research and production needs.

Ensure your thermal stress calculations are based on reality, not sensor error. Contact our experts today to discover how our precision hardware can enhance your lab's efficiency and safety.

Visual Guide

References

- Magdalena Jaremkiewicz. Analysis of the Accuracy of the Inverse Marching Method Used to Determine Thermal Stresses in Cylindrical Pressure Components with Holes. DOI: 10.3390/en18174546

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages of the Laser Hearth Method for Zirconia? Achieve High Purity & Density for Advanced Research

- What are the advantages of using a stainless steel fixed bed reactor for biochar pyrolysis? Unlock Precise Lab Results

- What are the advantages of using a microwave activation system? Unlock Superior Porosity and 90% Faster Activation

- What conditions are required for grafting norbornene functional groups onto S-glass fiber surfaces? Expert Protocol

- Why is a high-precision programmed heating furnace essential for the annealing reduction of intermetallic compounds?

- How do atomizers and furnaces function in Spray Pyrolysis? Master Nanoparticle Synthesis

- What function does high-purity argon gas serve in BPEA PVT preparation? Ensure High-Quality Crystal Growth

- What is the function of a planetary ball mill in magnesium production? Achieve Maximum Reaction Efficiency