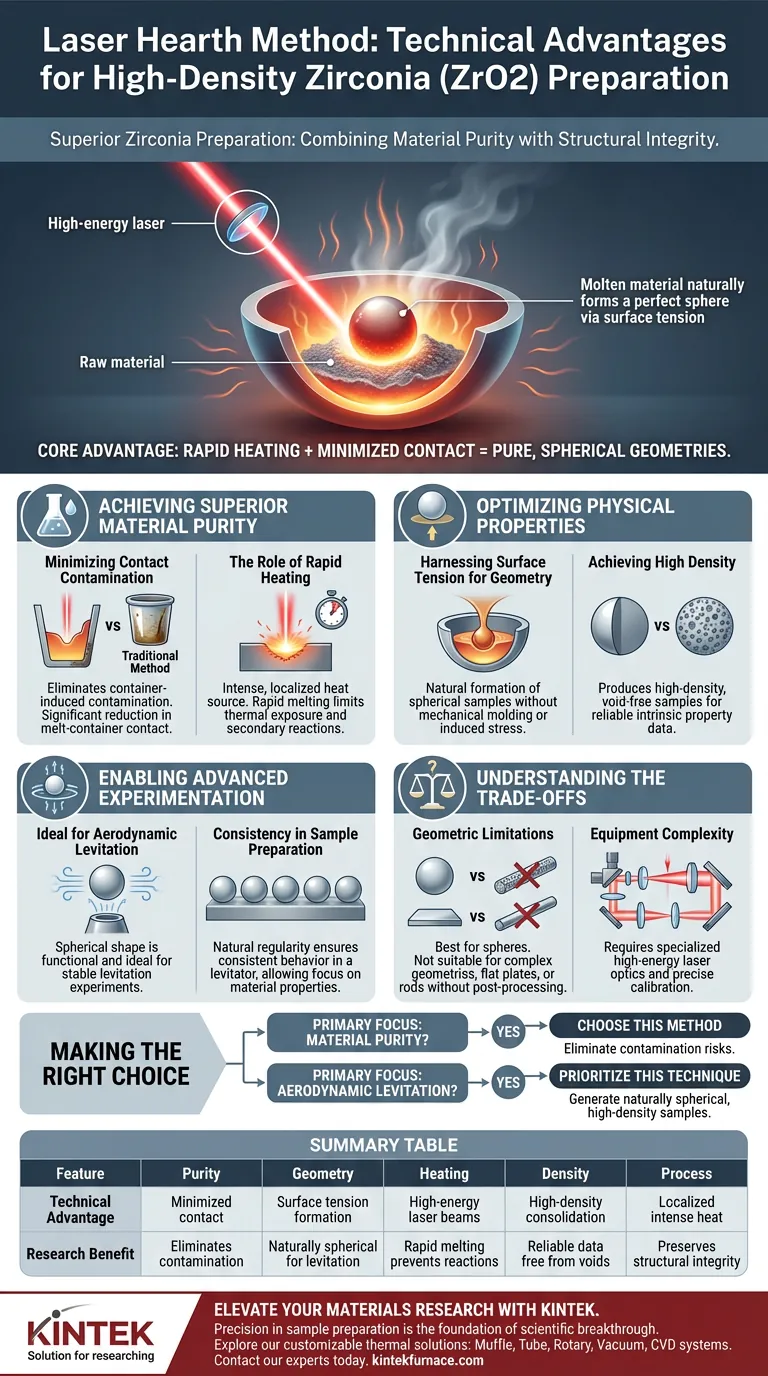

The Laser Hearth Method stands out as a superior technique for Zirconia preparation primarily due to its ability to maintain material purity while ensuring structural integrity. By utilizing high-energy laser beams to melt raw materials within a concave container, this process leverages surface tension to naturally form spherical samples. The result is a high-density product that avoids the contamination pitfalls common in traditional heating methods.

The core advantage of the Laser Hearth Method lies in its combination of rapid heating and minimized physical contact, which effectively eliminates container-induced contamination while producing the high-density, spherical geometries required for advanced aerodynamic levitation.

Achieving Superior Material Purity

Minimizing Contact Contamination

One of the most persistent challenges in preparing Zirconia at high temperatures is contamination from the crucible or container. Traditional methods often involve prolonged contact between the melt and the container walls. The Laser Hearth Method significantly reduces this interaction, ensuring the chemical composition of the Zirconia remains uncompromised.

The Role of Rapid Heating

High-energy lasers provide an intense, localized heat source that melts the material very quickly. This rapid heating profile limits the time window in which the material can react with its surroundings. By reducing the duration of thermal exposure required to achieve melting, the integrity of the raw material is preserved.

Optimizing Physical Properties

Harnessing Surface Tension for Geometry

The method utilizes a concave container which works in tandem with the physics of the molten material. As the Zirconia melts, surface tension naturally pulls the liquid into a spherical shape. This eliminates the need for mechanical molding, which can introduce stress or impurities.

Achieving High Density

Samples produced via this method exhibit high density, a critical factor for material characterization. High-density samples provide more reliable data regarding the intrinsic properties of Zirconia, free from the interference of porosity or voids often found in sintered samples.

Enabling Advanced Experimentation

Ideal for Aerodynamic Levitation

The spherical shape produced by the Laser Hearth Method is not merely aesthetic; it is functional. These regularly shaped spheres are specifically identified as being ideal for aerodynamic levitation experiments.

Consistency in Sample Preparation

Levitation experiments require precise aerodynamics to maintain stability. The natural regularity of the spheres produced by this method ensures consistent behavior in a levitator. This allows researchers to focus on the material properties rather than correcting for sample irregularities.

Understanding the Trade-offs

Geometric Limitations

While this method is excellent for creating spheres, it relies on surface tension to define the shape. If your project requires complex geometries, flat plates, or rods, this method will require significant post-process machining or may not be suitable.

Equipment Complexity

Unlike standard resistance furnaces, this method relies on high-energy laser optics. This implies a need for specialized equipment and precise calibration of the laser beam to ensure uniform melting within the concave container.

Making the Right Choice for Your Goal

To determine if the Laser Hearth Method is the correct approach for your Zirconia samples, consider your specific end-use requirements:

- If your primary focus is material purity: Choose this method to eliminate the contamination risks associated with prolonged container wall contact at high temperatures.

- If your primary focus is aerodynamic levitation: Prioritize this technique to generate the naturally spherical, high-density samples essential for stable levitation dynamics.

This method effectively bridges the gap between high-temperature processing and the need for pristine, geometrically regular samples.

Summary Table:

| Feature | Technical Advantage | Research Benefit |

|---|---|---|

| Purity | Minimized container contact | Eliminates chemical contamination |

| Geometry | Surface tension formation | Naturally spherical for aerodynamic levitation |

| Heating | High-energy laser beams | Rapid melting prevents secondary reactions |

| Density | High-density consolidation | Reliable data free from porosity or voids |

| Process | Localized intense heat | Preserves structural and chemical integrity |

Elevate Your Materials Research with KINTEK

Precision in sample preparation is the foundation of scientific breakthrough. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are preparing high-purity Zirconia or exploring advanced aerodynamic levitation, our lab high-temp furnaces are fully customizable to meet your unique experimental needs.

Ready to optimize your high-temperature processing? Contact our experts today to find the perfect specialized heating solution for your laboratory.

Visual Guide

References

- Yaopeng Gong, Weimin Ma. Non-Contact Thermophysical Property Measurements of High-Temperature Corium Through Aerodynamic Levitation. DOI: 10.3390/en18010136

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Spark Plasma Sintering SPS Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What are the three steps parts go through in a conveyor furnace? Master Sintering for Stronger Parts

- How does a constant temperature drying oven contribute to MgTiO3-CaTiO3 ceramic slurry? Optimize Your Precursor Quality

- What function does high-purity argon gas serve in BPEA PVT preparation? Ensure High-Quality Crystal Growth

- What is the function of a drying oven in the post-treatment process of Ni and Zn-doped MgO nanoparticles?

- What is the importance of a stable thermal environment during crystallization? Ensure Precision in Metal Oxide Films

- What is the function of a constant temperature blast drying oven? Achieve Uniform Chemical Activation and Porosity

- Why is it necessary to dry glassware in a 140 °C oven overnight before GTP? Ensure Precise Anhydrous Polymerization

- What is the significance of preheating UHPC molds? Ensure Safety & Longevity with High-Temp Furnaces