The primary advantage of a stainless steel fixed bed reactor is its ability to create a precisely controlled, oxygen-free thermal environment essential for high-quality biochar production. Its superior high-temperature resistance and structural integrity ensure stable thermal conduction. This allows researchers to maintain a constant flow of inert gas (like nitrogen), resulting in the uniform carbonization of biomass materials.

By combining robust material strength with a sealed, inert atmosphere, this reactor design transforms variable biomass into consistent biochar with predictable porosity and carbon content. It is the ideal vessel for isolating variables during thermal degradation.

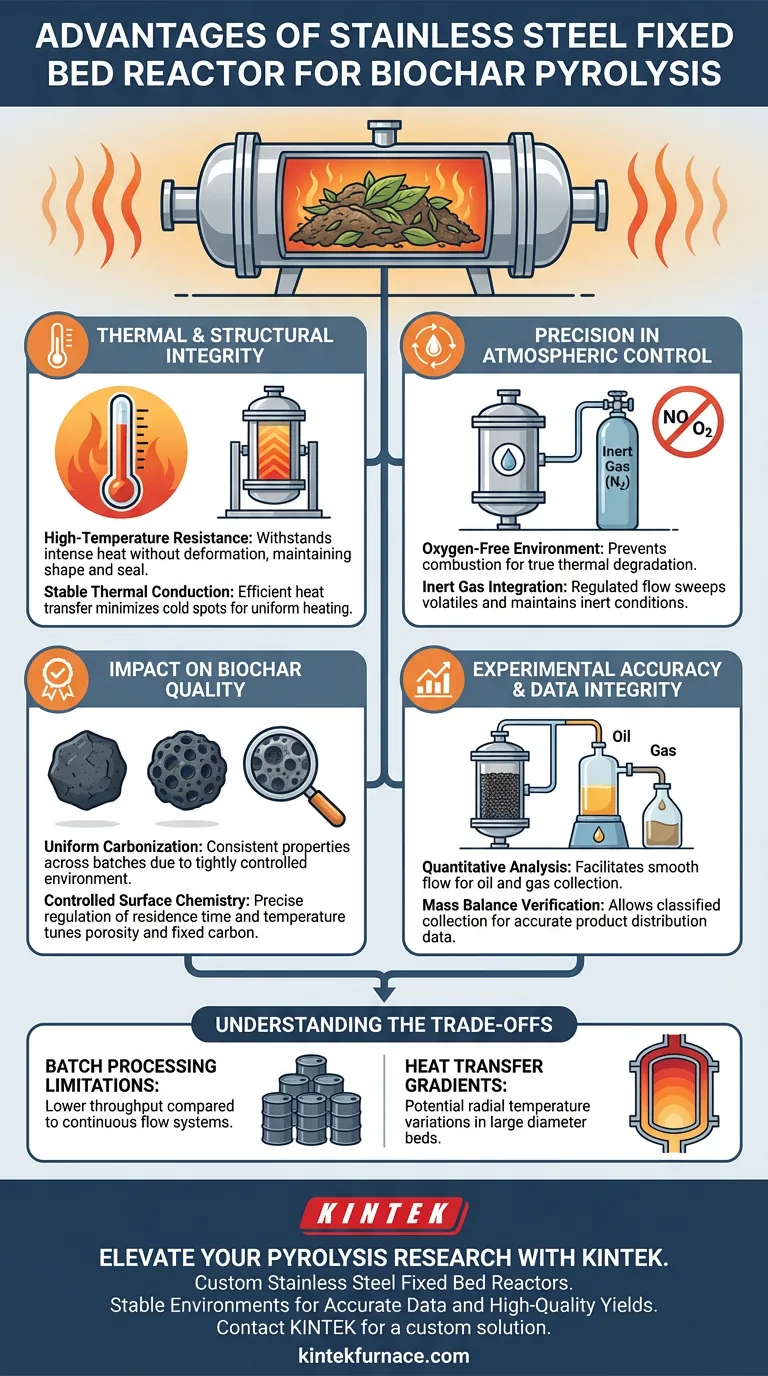

Thermal and Structural Integrity

High-Temperature Resistance

Stainless steel is selected for these reactors specifically for its ability to withstand the intense heat required for pyrolysis without deforming.

This structural resilience ensures the reactor maintains its shape and seal integrity throughout the heating cycle.

Stable Thermal Conduction

The material properties of the reactor provide a stable thermal conduction space.

This ensures that heat is transferred efficiently from the furnace to the biomass, minimizing cold spots that could lead to incomplete carbonization.

Precision in Atmospheric Control

The Oxygen-Free Environment

A critical requirement for pyrolysis is the absence of oxygen to prevent combustion.

The sealed design of the stainless steel fixed bed reactor creates a completely isolated environment, ensuring true thermal degradation rather than burning.

Inert Gas Integration

These reactors are engineered with integrated gas inlets and outlets to manage the atmosphere.

This allows for a constant, regulated flow of carrier gas (such as nitrogen), which sweeps away volatile vapors and maintains the inert conditions necessary for converting biomass like Moringa oleifera seed shells into char.

Impact on Biochar Quality

Uniform Carbonization

Because the environment and temperature are tightly controlled, the resulting biochar exhibits uniform carbonization.

This consistency is vital for applications where the physical and chemical properties of the char must remain constant across different batches.

Controlled Surface Chemistry

The fixed-bed setup allows for precise regulation of residence time and temperature.

This control drives the specific thermal degradation required to produce biochar with distinct fixed carbon content, porosity, and surface chemistry.

Experimental Accuracy and Data Integrity

Quantitative Analysis

The structural design, often featuring a horizontal tube, facilitates the smooth flow of pyrolysis-generated oil and gas mixtures into a condensation system.

Mass Balance Verification

This flow management allows for the classified collection of oil, gas, and solid residues.

Researchers can perform accurate quantitative analysis and mass balance calculations, ensuring the integrity of product distribution data for experimental purposes.

Understanding the Trade-offs

Batch Processing Limitations

Fixed bed reactors are typically batch systems, meaning they process a finite amount of biomass at a time.

While excellent for quality control and research, they generally offer lower throughput compared to continuous flow reactors used in large-scale industrial operations.

Heat Transfer Gradients

While stainless steel conducts heat well, extremely large fixed beds can suffer from radial temperature gradients.

If the reactor diameter is too wide, heat may not penetrate to the center of the biomass bed as effectively as the outer edges, potentially affecting uniformity.

Making the Right Choice for Your Goal

To maximize the value of a stainless steel fixed bed reactor, align its capabilities with your specific objectives.

- If your primary focus is Fundamental Research: Leverage the sealed design and gas collection systems to perform precise mass balance calculations and characterize pyrolysis oil and gas yields.

- If your primary focus is Material Engineering: Utilize the precise temperature control to manipulate residence times, tuning the porosity and surface area of the biochar for specific adsorption applications.

Reliable biochar production begins with a reactor that eliminates variables, ensuring that every change in the product is a result of your design, not equipment failure.

Summary Table:

| Feature | Advantage for Biochar Pyrolysis |

|---|---|

| Material Strength | Resists high temperatures without deformation, ensuring seal integrity. |

| Atmospheric Control | Sealed design maintains oxygen-free conditions to prevent biomass combustion. |

| Thermal Conduction | Provides uniform heat transfer for consistent carbonization and porosity. |

| Gas Management | Integrated inlets allow inert gas flow to sweep volatiles for mass balance analysis. |

| System Design | Horizontal tube structures facilitate easy collection of oils, gases, and solids. |

Elevate Your Pyrolysis Research with KINTEK

Precision in biochar production starts with superior equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized as stainless steel fixed bed reactors to meet your unique experimental needs.

Whether you are focusing on material engineering or fundamental thermal degradation, our lab high-temp furnaces provide the stable environment necessary for accurate data and high-quality yields.

Ready to optimize your carbonization process? Contact KINTEK today for a custom solution.

Visual Guide

References

- Caio Henrique da Silva, Wardleison Martins Moreira. Synthesis of Activated Biochar from the Bark of Moringa oleifera for Adsorption of the Drug Metronidazole Present in Aqueous Medium. DOI: 10.3390/pr12030560

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What is the purpose of the sulfidation treatment process? Enhance Reactor Performance with DMDS Passivation

- Why is an 800 °C heat treatment for Ti6Al4V additive manufacturing necessary? Unlock Ductility & Relieve Stress

- What is the main benefit of using a benchtop industrial oven? Save Space and Boost Efficiency in Your Lab

- Why are Cu2O and Ga2O3 targets preferred for CuGaO2 films? Achieving Precision in Delafossite Sputtering

- How does an annealing furnace improve Indium Selenide thin films? Optimize Your Photoanode Energy Efficiency Today

- What are the complexities and maintenance requirements of continuous furnaces? Optimize High-Volume Production with Expert Insights

- How does the holding time in a high-temperature furnace affect 0W Fe-C-B-Cr-W alloys? Optimize Phase Dissolution

- Why must catalysts undergo high-temperature pretreatment? Ensure Precise CO Oxidation Data with KINTEK