The necessity of an 800 °C heat treatment using a laboratory high-temperature furnace stems directly from the rapid thermal dynamics of the additive manufacturing process.

During 3D printing, Ti6Al4V cools at an extreme rate, freezing the metal into an unstable, brittle state known as non-equilibrium alpha prime martensite. The 800 °C treatment is required to provide the thermal energy needed to decompose this unstable phase into stable alpha and beta phases, thereby eliminating residual stresses and significantly improving the material's ductility and toughness.

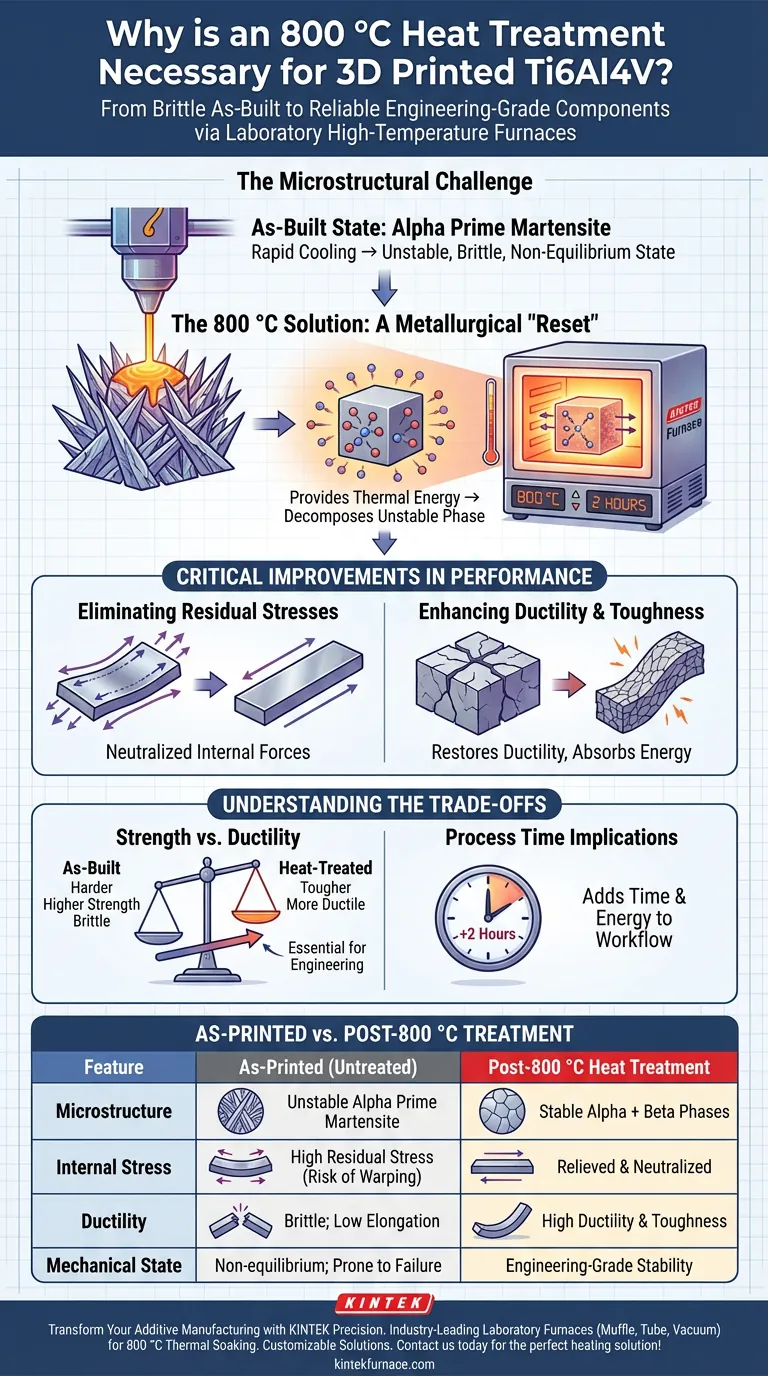

The rapid cooling inherent in 3D printing locks Ti6Al4V into a brittle, highly stressed structure. An 800 °C heat treatment acts as a metallurgical "reset," transforming the microstructure into a stable form that provides the ductility required for structural reliability.

The Microstructural Challenge of Additive Manufacturing

The Consequence of Rapid Cooling

Additive manufacturing involves melting metal powder and allowing it to solidify almost instantly.

This rapid cooling rate prevents the titanium alloy atoms from arranging themselves into their natural, equilibrium state.

Creating Alpha Prime Martensite

Instead of forming the standard alpha and beta phases, the fast solidification creates a needle-like structure called alpha prime martensite.

While this phase is hard, it is chemically unstable (non-equilibrium) and inherently brittle, making the "as-built" part prone to failure under load.

The Mechanism of Phase Transformation

Driving Decomposition at 800 °C

Holding the material at 800 °C for 2 hours provides the necessary activation energy for atomic diffusion.

This thermal soak allows the unstable alpha prime martensite to decompose completely.

Achieving Stability

Through this process, the microstructure transforms into a mixture of stable alpha and beta phases.

This equilibrium structure is the standard for Titanium alloys, offering a predictable balance of properties that the "as-built" structure cannot match.

Critical Improvements in Performance

Eliminating Residual Stresses

The layer-by-layer printing process introduces significant internal tension, known as residual stress.

If left untreated, these stresses can cause the part to warp or crack; the heat treatment relaxes the material, effectively neutralizing these internal forces.

Enhancing Ductility and Toughness

The most vital outcome of converting martensite to alpha-beta phases is the restoration of ductility.

While the as-printed material is brittle and glass-like, the heat-treated material becomes tough, meaning it can absorb energy and deform slightly without fracturing.

Understanding the Trade-offs

Strength vs. Ductility Balance

While heat treatment is necessary for toughness, it is important to note that the "as-built" martensitic structure is often harder and has higher tensile strength than the heat-treated version.

However, this strength comes at the cost of extreme brittleness, making the trade-off for increased ductility usually essential for engineering applications.

Process Time Implications

Implementing a 2-hour soak at 800 °C adds time and energy costs to the manufacturing workflow.

This step must be accounted for in production scheduling, as the cooling cycle inside the furnace will extend the total processing time beyond the 2-hour hold.

Ensuring Material Reliability

To ensure your Ti6Al4V components perform as intended, apply this heat treatment strategy based on your specific requirements:

- If your primary focus is structural integrity: Use the 800 °C treatment to eliminate residual stresses that could lead to unpredictable warping or cracking.

- If your primary focus is impact resistance: Rely on the phase transformation to convert brittle martensite into tough alpha-beta phases that can withstand shock.

By standardizing this heat treatment, you transform a printed geometry into a reliable, engineering-grade component.

Summary Table:

| Feature | As-Printed (Untreated) | Post-800 °C Heat Treatment |

|---|---|---|

| Microstructure | Unstable Alpha Prime Martensite | Stable Alpha + Beta Phases |

| Internal Stress | High Residual Stress (Risk of Warping) | Relieved & Neutralized |

| Ductility | Brittle; Low Elongation | High Ductility & Toughness |

| Mechanical State | Non-equilibrium; Prone to Failure | Engineering-Grade Stability |

Transform Your Additive Manufacturing with KINTEK Precision

Don't let residual stress compromise your structural integrity. KINTEK provides industry-leading laboratory high-temperature furnaces, including Muffle, Tube, and Vacuum systems, specifically engineered to handle the rigorous 800 °C thermal soaking required for Ti6Al4V.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique metallurgical needs. Ensure your components meet the highest standards of toughness and reliability—contact us today to find the perfect heating solution for your lab!

Visual Guide

References

- COMPARISON OF POWDER-BED FUSION, DIRECTED-ENERGY DEPOSITION AND HYBRID ADDITIVE MANUFACTURING OF Ti6Al4V COMPONENTS: MICROSTRUCTURE, CORROSION AND MECHANICAL PROPERTIES. DOI: 10.17222/mit.2024.1423

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of PVD coating? Achieve Precision, Purity, and Eco-Friendly Performance

- What type of reaction environment is required for the synthesis of Ge-Se-Tl-Sb chalcogenide glasses? | KINTEK

- What is the function of the annealing furnace? Strategically Control Material Properties for Reliability

- Why is charcoal used as a susceptor material during the microwave cladding of FeCoNiMnCu? Unlock efficient heating.

- What are the advantages of Zr2Cu alloy over pure zirconium in RMI? Optimize Fiber Integrity at Lower Temperatures

- How do lab high-temp furnaces and air quenching coordinate in o-LISO synthesis? Master the Thermal Transition

- Why is a temperature-controlled heating system required for firing silver electrodes? Ensure Precision Ohmic Contacts

- What technical advantages does a custom high-temperature furnace provide for in-situ diffraction on molten sulfur?