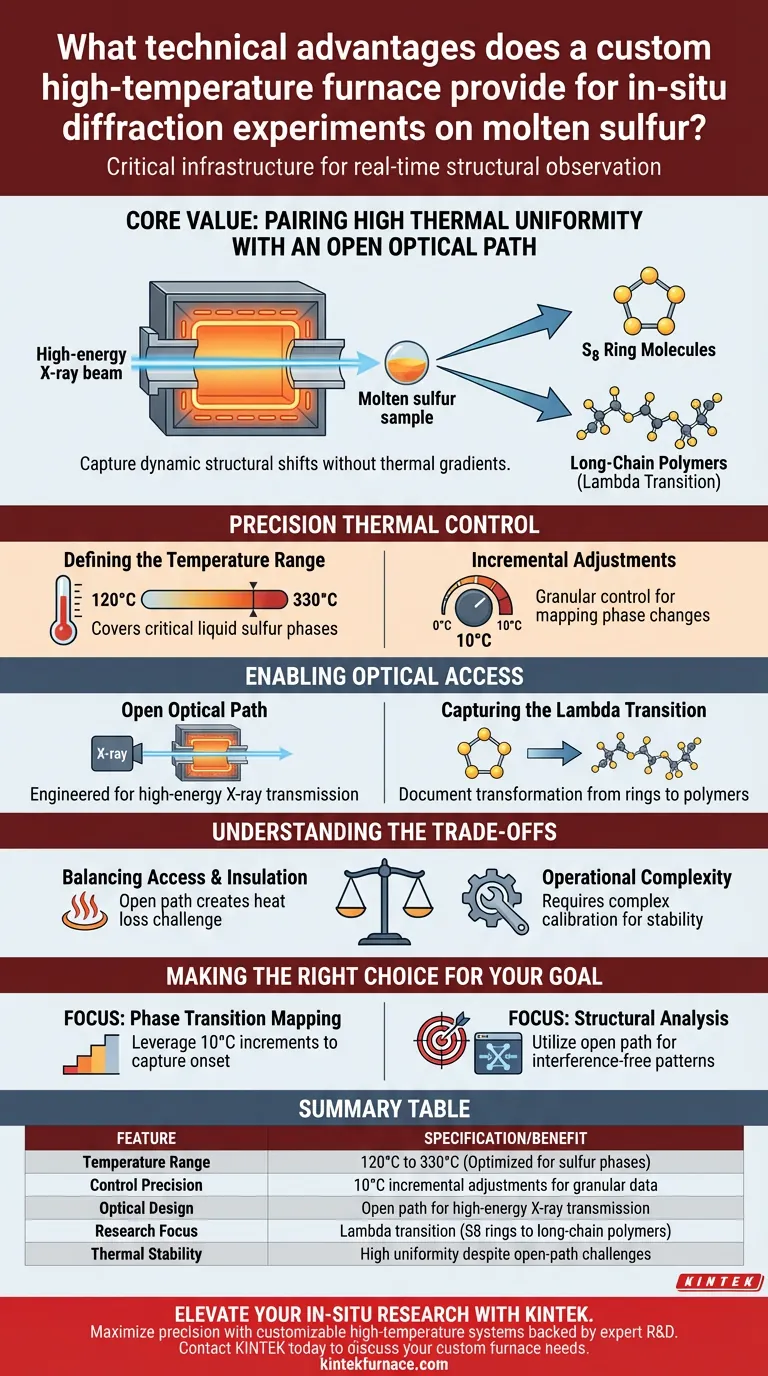

A custom high-temperature furnace serves as the critical infrastructure for observing the structural evolution of molten sulfur in real-time. It provides a stable thermal environment ranging from 120°C to 330°C, allowing for precise temperature regulation in 10°C increments to facilitate detailed data collection.

The core value of this apparatus lies in its ability to pair high thermal uniformity with an open optical path. This specific combination allows researchers to capture the dynamic structural shift from S8 ring molecules to long-chain polymers without thermal gradients distorting the observation.

Precision Thermal Control

Defining the Temperature Range

To effectively study molten sulfur, the equipment must maintain stability across a specific thermal window. This custom furnace operates reliably between 120°C and 330°C. This range covers the critical phases of sulfur's liquid state necessary for in-situ diffraction.

The Importance of Incremental Adjustments

Granular control is essential when mapping phase changes. The furnace allows for adjustments in 10°C increments, enabling researchers to step through temperature gradients methodically. This precision is vital for isolating specific moments of structural change during the experiment.

Enabling Optical Access

The Open Optical Path

Standard furnaces often obstruct the line of sight required for diffraction methods. This custom design features an open optical path, specifically engineered to allow high-energy X-rays to pass through the heating element and interact with the sample.

Capturing the Lambda Transition

The primary goal of this optical design is to record dynamic structural information. By permitting X-ray transmission, the system can document the lambda transition, where sulfur transforms from S8 ring molecules into complex long-chain polymers.

Understanding the Trade-offs

Balancing Access and Insulation

While the open optical path is necessary for diffraction, it introduces a challenge regarding thermal containment. The system must work harder to maintain high temperature uniformity because the opening creates a potential avenue for heat loss.

Operational Complexity

Achieving stability at 330°C with precise 10°C increments requires a more complex calibration process than standard heating units. Users must ensure the apparatus is perfectly tuned to prevent thermal fluctuations that could obscure the subtle transition from rings to polymers.

Making the Right Choice for Your Goal

To maximize the utility of this custom furnace, align your experimental protocols with its specific technical strengths:

- If your primary focus is Phase Transition Mapping: Leverage the 10°C increments to slowly increase temperature, ensuring you capture the exact onset of the lambda transition.

- If your primary focus is Structural Analysis: Utilize the open optical path to direct high-energy X-rays at the sample, ensuring the resulting diffraction patterns are free from equipment interference.

Precision thermal control combined with optical accessibility is the key to unlocking the dynamic structural behavior of sulfur.

Summary Table:

| Feature | Specification/Benefit |

|---|---|

| Temperature Range | 120°C to 330°C (Optimized for sulfur phases) |

| Control Precision | 10°C incremental adjustments for granular data |

| Optical Design | Open path for high-energy X-ray transmission |

| Research Focus | Lambda transition (S8 rings to long-chain polymers) |

| Thermal Stability | High uniformity despite open-path heat loss challenges |

Elevate Your In-Situ Research with KINTEK

Maximize the precision of your structural analysis with a furnace engineered for your exact experimental parameters. Backed by expert R&D and world-class manufacturing, KINTEK provides specialized Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of lab high-temperature research.

Whether you need an open optical path for diffraction or extreme thermal uniformity for phase transition mapping, our engineers will help you design the perfect solution. Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- The Structure of Glassy and Liquid Sulfur Revisited. DOI: 10.52825/glass-europe.v3i.2532

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a Flash Sintering (FS) system improve efficiency? Unlock Rapid Production for Titanium Diboride Composites

- What are the advantages of using an industrial-grade rapid heating furnace? Maximize Glass-Ceramic Debinding Efficiency

- What is the primary design purpose of industrial electric furnaces for SA-178 Gr A steel? Ensure Pipe End Reliability

- What role does the annealing process play in the post-treatment of stir-cast aluminum matrix composites? | KINTEK

- Why is Water Quenching Critical for Metastable Phases in Titanium? Unlock High-Performance Alloy Strength

- Why are high frequencies used in induction heating? For Precise, Rapid Surface Heating

- What is the role of MgO powder in Nickel-Aluminum VCS? Achieve Precise Thermal Control & Powder Quality

- How does a high-sensitivity non-contact microphone assist in detecting cracks during the solidification of molten slag?