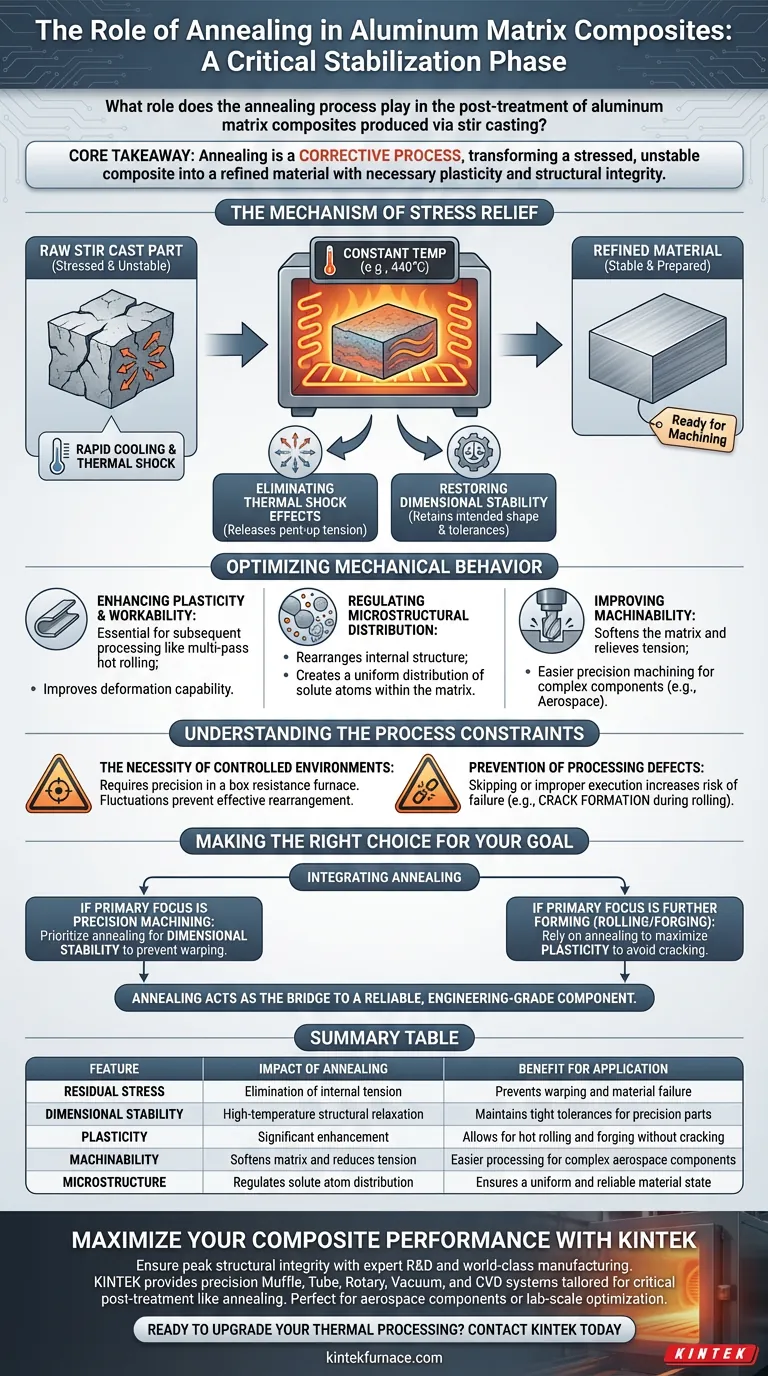

Annealing serves as a critical stabilization phase in the post-treatment of aluminum matrix composites, designed to eliminate residual stresses accumulated during the stir casting process. By subjecting the composite to a controlled, constant-temperature environment, this heat treatment relaxes the material's internal structure, ensuring it is dimensionally stable and physically prepared for machining or high-performance applications.

Core Takeaway Annealing is not merely about heating; it is a corrective process that neutralizes the thermal shock of rapid cooling. It transforms a composite from a stressed, potentially unstable state into a refined material with the necessary plasticity and structural integrity for aerospace components and complex machining.

The Mechanism of Stress Relief

Eliminating Thermal Shock Effects

During stir casting, the material undergoes intense heating followed by rapid cooling. This temperature fluctuation locks residual stresses deep within the composite's matrix. Annealing uses high-temperature furnaces to release this pent-up tension safely.

Restoring Dimensional Stability

If these residual stresses remain, the material may warp or deform unpredictably over time. The annealing process ensures dimensional stability, meaning the component retains its intended shape and tolerances even under mechanical load.

Optimizing Mechanical Behavior

Enhancing Plasticity and Workability

Beyond stress relief, annealing significantly improves the material's plasticity. This modification is essential if the composite will undergo subsequent processing, such as multi-pass hot rolling.

Regulating Microstructural Distribution

The process allows for the rearrangement of the internal microstructure. Specifically, it helps regulate the distribution of solute atoms within the aluminum matrix, creating a more uniform internal state.

Improving Machinability

By softening the matrix and relieving tension, the composite becomes easier to machine. This optimization is particularly vital for precision sectors like aerospace, where material failure during machining is unacceptable.

Understanding the Process Constraints

The Necessity of Controlled Environments

Annealing requires precision; it is typically conducted in a box resistance furnace to maintain a stable, constant temperature (e.g., 440 °C). Fluctuations in this environment can prevent the effective rearrangement of the microstructure.

Prevention of Processing Defects

Skipping or improperly executing this stage introduces a high risk of failure. Without the plasticity gained from annealing, the material is prone to crack formation during subsequent mechanical processing or rolling.

Making the Right Choice for Your Goal

When integrating annealing into your production line, consider your downstream requirements:

- If your primary focus is Precision Machining: Prioritize annealing to ensure dimensional stability, preventing warping when material is removed.

- If your primary focus is Further Forming (Rolling/Forging): Rely on annealing to maximize plasticity, ensuring the material can deform without cracking.

Annealing acts as the bridge between a raw cast part and a reliable, engineering-grade component.

Summary Table:

| Feature | Impact of Annealing | Benefit for Application |

|---|---|---|

| Residual Stress | Elimination of internal tension | Prevents warping and material failure |

| Dimensional Stability | High-temperature structural relaxation | Maintains tight tolerances for precision parts |

| Plasticity | Significant enhancement | Allows for hot rolling and forging without cracking |

| Machinability | Softens matrix and reduces tension | Easier processing for complex aerospace components |

| Microstructure | Regulates solute atom distribution | Ensures a uniform and reliable material state |

Maximize Your Composite Performance with KINTEK

Ensure your aluminum matrix composites achieve peak structural integrity and dimensional stability. Backed by expert R&D and world-class manufacturing, KINTEK provides precision Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for critical post-treatment processes like annealing.

Whether you are refining aerospace components or optimizing lab-scale stir casting, our customizable high-temperature furnaces deliver the thermal precision required to eliminate stress and enhance workability.

Ready to upgrade your thermal processing? Contact KINTEK today to find the perfect solution for your unique manufacturing needs!

Visual Guide

References

- Naguib G. Yakoub. Catalysts of Strength: Unveiling the Mechanical and Tribological Mastery of Al-2024 MMC with Fly ash/TiB2/SiC Reinforcements. DOI: 10.21608/jessit.2024.283185.1010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is high-precision temperature control of the heating base critical during FTO spray pyrolysis? Maximize Film Quality

- What are the technical advantages of using a six-zone resistance heating furnace in VGF-VB? Unlock Precision Growth

- Why must Sm:YAG ceramics undergo air annealing? Restoring Optical Clarity and Restructuring Defects

- What is the primary purpose of 24-hour wet milling for SSBSN ceramics? Achieve Atomic-Scale Homogeneity

- What is the primary function of an electric furnace in PBG melting? Expert Guide to Thermal Homogeneity

- What role does a laboratory circulating air drying oven play in the post-treatment of composite membranes? Master Stability

- What is the primary function of the low-temperature pyrolysis process? Ensure Safe Battery Recycling with Pretreatment

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control