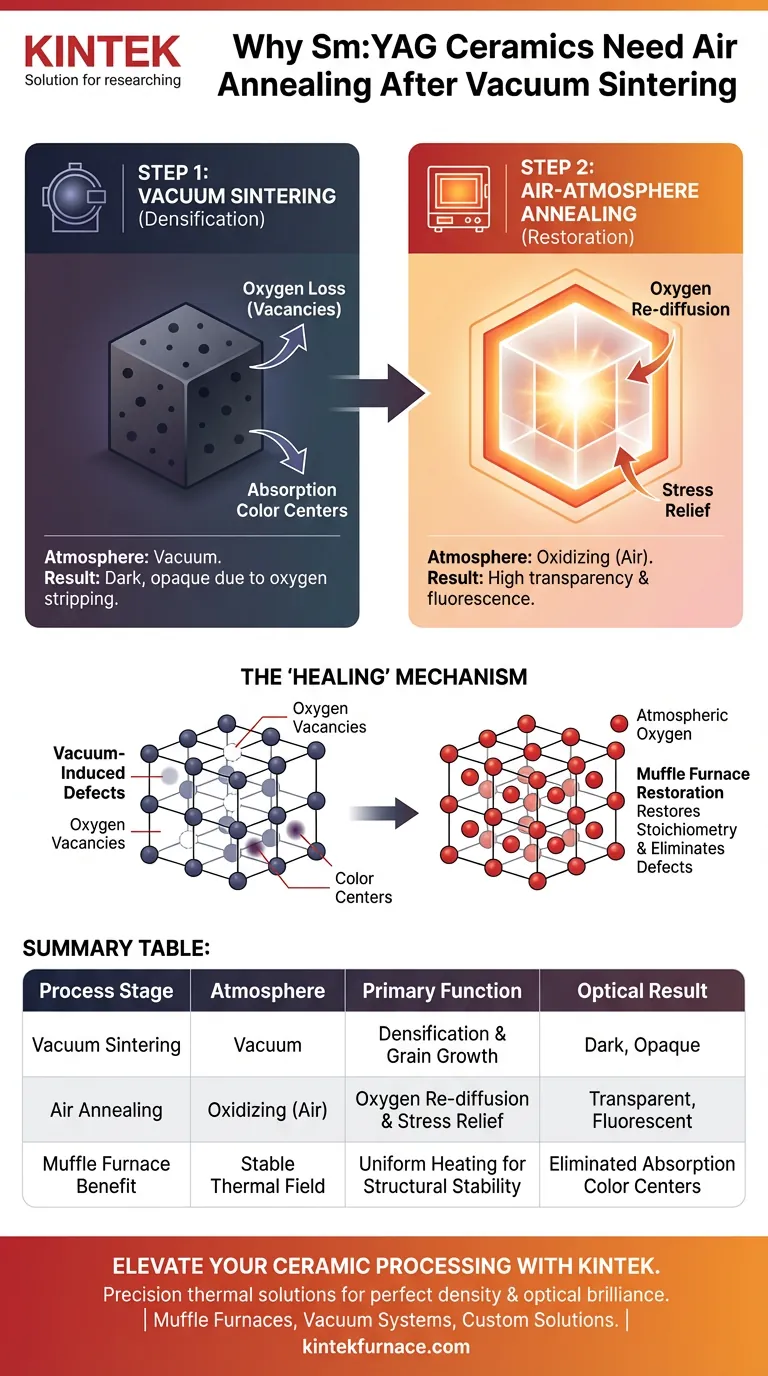

The annealing of Sm:YAG ceramics in an air-atmosphere muffle furnace is required to repair the chemical and optical damage caused by vacuum sintering. While vacuum sintering is necessary for densification, it strips oxygen from the material, creating oxygen vacancies and absorption color centers. Annealing in an air atmosphere provides the necessary oxidizing environment to reverse this process, re-diffusing oxygen into the lattice and restoring transparency.

Core Takeaway Vacuum sintering disrupts the stoichiometric ratio of Sm:YAG ceramics, resulting in dark, opaque materials due to oxygen loss. Air annealing acts as a corrective "healing" phase, eliminating these vacancies and releasing internal stresses to ensure the ceramic achieves high light transmission and optimal fluorescence.

Understanding the Vacuum-Induced Defects

The Formation of Oxygen Vacancies

When Sm:YAG ceramics are processed in a vacuum environment, the lack of atmospheric oxygen causes oxygen ions to escape the crystal lattice. This results in significant oxygen vacancies, effectively altering the chemical balance (stoichiometry) of the material.

Appearance of Absorption Color Centers

These oxygen vacancies lead to the formation of absorption color centers within the ceramic structure. Instead of passing light through, these centers absorb it, which compromises the optical performance of the material.

The Restoration Process in the Muffle Furnace

Restoring Stoichiometry via Oxidation

The muffle furnace provides a high-temperature, stable oxidizing environment. This atmosphere forces oxygen ions to diffuse back into the ceramic, filling the vacancies created during the vacuum stage and restoring the material's correct stoichiometric ratio.

Regaining Optical Properties

As the oxygen vacancies are eliminated, the absorption color centers disappear. This allows the Sm:YAG ceramic to regain its critical light transmission properties and excellent fluorescence emission characteristics.

Releasing Internal Stresses

Beyond chemical repair, the annealing process serves a mechanical function. The controlled thermal environment allows for the release of sintering stresses that accumulated during the initial densification, ensuring the material is structurally stable.

Ensuring Uniform Heating

The muffle furnace prevents direct exposure to flames and ensures a uniform thermal field. This uniformity promotes synchronized grain growth (as noted in general oxide ceramic processing), resulting in a dense, equiaxed grain structure that supports optical clarity.

Understanding the Trade-offs

The Cost of Optical Clarity

Achieving high optical performance in Sm:YAG ceramics prevents the use of a single-step sintering process. Manufacturers must accept the operational "cost" of a two-step cycle: using a vacuum to achieve density, followed by a separate, time-consuming air annealing step to correct the resulting chemical defects.

Atmosphere vs. Density

You cannot achieve both full densification and perfect stoichiometry in a single vacuum step. The vacuum environment that aids in densification inherently promotes reduction reactions (oxygen loss). Therefore, the process relies on the muffle furnace to act as a distinct chemical stabilizer after the physical structure is formed.

Making the Right Choice for Your Goal

To optimize the production of Sm:YAG ceramics, align your process parameters with your specific performance requirements:

- If your primary focus is Optical Transparency: Ensure the annealing duration in the muffle furnace is sufficient to allow complete oxygen re-diffusion throughout the entire volume of the ceramic.

- If your primary focus is Mechanical Stability: Prioritize the uniformity of the thermal field in the muffle furnace to effectively release sintering stresses without inducing new thermal gradients.

By separating the densification and oxidation stages, you ensure the final ceramic possesses both the structural density and the optical brilliance required for high-performance applications.

Summary Table:

| Process Stage | Atmosphere | Primary Function | Optical Result |

|---|---|---|---|

| Vacuum Sintering | Vacuum | Material densification & grain growth | Dark, opaque due to oxygen loss |

| Air Annealing | Oxidizing (Air) | Re-diffusion of oxygen & stress relief | High transparency & fluorescence |

| Benefit of Muffle Furnace | Stable Thermal Field | Uniform heating for structural stability | Eliminated absorption color centers |

Elevate Your Ceramic Processing with KINTEK

Achieving the perfect balance between density and optical brilliance in Sm:YAG ceramics requires precise control over your thermal environment. At KINTEK, we specialize in providing high-performance, customizable heating solutions designed to meet the rigorous demands of advanced material science.

Why choose KINTEK for your lab?

- Expert R&D & Manufacturing: Our systems are engineered for uniform thermal fields and stable oxidizing atmospheres.

- Versatile Systems: From specialized Muffle Furnaces and Vacuum Systems to CVD and Rotary Furnaces, we offer the full spectrum of high-temp equipment.

- Customized Solutions: We tailor our lab furnaces to your unique sintering and annealing requirements.

Don't let oxygen vacancies compromise your material performance. Contact us today to discover how KINTEK's precision technology can optimize your production and ensure superior optical results!

Visual Guide

References

- Lahbib Abbas, Zahra Ramzi. Graphite Carbone Structure. DOI: 10.4236/csta.2024.121001

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does a Zinc Oxide (ZnO) catalyst affect PET pyrolysis? Optimize Yields & Efficiency

- What is the function of a rotary high-pressure autoclave in the synthesis of SSZ-13 zeolites? | Enhance Crystallinity

- Why do VTD sublimation capsules need specialized designs for perovskite? Achieve Precise Film Uniformity and Stability

- What is the significance of high-precision temperature monitoring systems in SPS? Control Ti-6Al-4V/HA Microstructure

- How do segmented heating and cooling cycles affect the microwave-assisted synthesis of 2D iron oxide (Fe2O3)?

- How does a solvothermal reactor contribute to silver nanowires synthesis? Precision Growth for High-Aspect-Ratio AgNWs

- Why are User-Defined Functions (UDFs) necessary for modeling complex combustion? Unlock Precision in Furnace Simulation

- What role does a releasing agent play during the assembly process of titanium-steel composite plates?