A releasing agent serves as a critical anti-bonding barrier during the manufacturing of titanium-steel composite plates. Specifically, in a symmetric assembly structure, this agent is applied to the interface between two titanium plates to prevent them from fusing together under the intense conditions of production.

The releasing agent allows for the simultaneous rolling of two plates in a single stack by ensuring the titanium layers remain distinct, enabling the final separation of two individual single-sided composite plates.

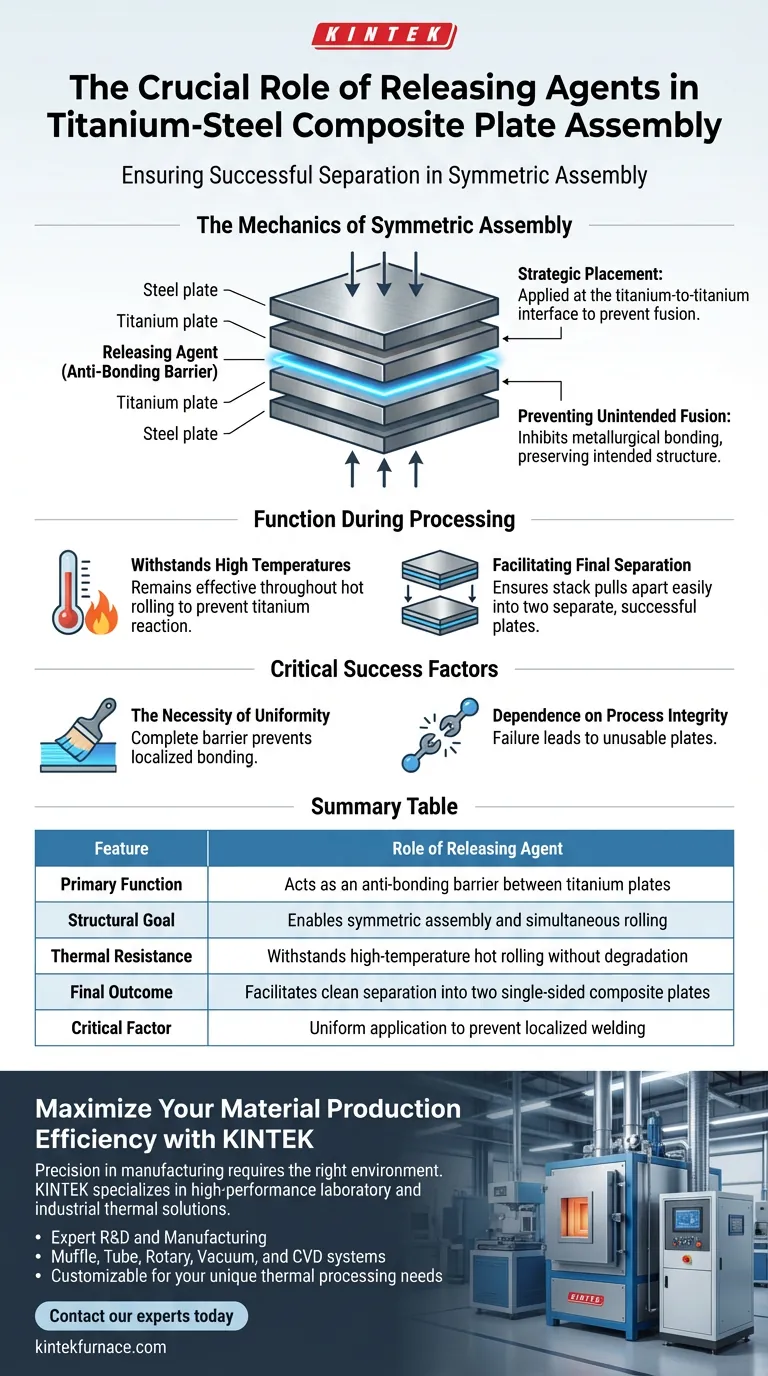

The Mechanics of Symmetric Assembly

Strategic Placement

In a symmetric assembly method, the manufacturing stack is arranged so that two titanium plates face each other.

The releasing agent is applied directly to this interface between the two titanium surfaces.

Preventing Unintended Fusion

The core purpose of this agent is to inhibit metallurgical bonding between the matching titanium layers.

Without this barrier, the two titanium plates would essentially weld together, destroying the intended structure of the final product.

Function During Processing

Withstanding High Temperatures

The assembly process involves high-temperature hot rolling to bond the titanium to the steel.

The releasing agent must remain effective throughout this thermal cycle to prevent the titanium-to-titanium interface from reacting.

Facilitating Final Separation

The ultimate goal of the symmetric assembly is to produce single-sided composite plates.

Once the hot rolling is complete, the releasing agent ensures the stack can be easily pulled apart, yielding two separate, successful composite plates.

Critical Success Factors

The Necessity of Uniformity

For the releasing agent to function correctly, it must create a complete barrier across the interface.

Any failure in the agent's coverage could lead to unintended localized bonding, making separation impossible.

Dependence on Process Integrity

The success of the entire symmetric assembly relies on this specific chemical barrier.

If the agent degrades or fails during rolling, the separation phase will fail, rendering the composite plates unusable.

Ensuring Production Success

To maximize the effectiveness of the assembly process:

- If your primary focus is Production Efficiency: Ensure the releasing agent is applied consistently to allow for the simultaneous processing of two plates without separation issues.

- If your primary focus is Material Integrity: Verify that the releasing agent is compatible with the specific temperatures of the hot rolling process to prevent unintended fusion.

The releasing agent is the defining component that transforms a bonded stack into two usable, independent composite plates.

Summary Table:

| Feature | Role of Releasing Agent |

|---|---|

| Primary Function | Acts as an anti-bonding barrier between titanium plates |

| Structural Goal | Enables symmetric assembly and simultaneous rolling |

| Thermal Resistance | Withstands high-temperature hot rolling without degradation |

| Final Outcome | Facilitates clean separation into two single-sided composite plates |

| Critical Factor | Uniform application to prevent localized welding |

Maximize Your Material Production Efficiency with KINTEK

Precision in the manufacturing process of titanium-steel composite plates requires the right environment and equipment. At KINTEK, we specialize in providing high-performance laboratory and industrial solutions tailored for advanced material processing.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable for your unique thermal processing needs. Whether you are refining your symmetric assembly techniques or testing new metallurgical barriers, our equipment ensures the consistency and temperature control your success demands.

Ready to optimize your production and ensure material integrity? Contact our experts today to discuss how our custom furnace solutions can benefit your lab or facility.

Visual Guide

References

- Juan Pu, Yunxia Chen. Effect of Heat Treatment Temperature on the Microstructure and Properties of Titanium-Clad Steel Plate Prepared by Vacuum Hot Rolling. DOI: 10.3390/coatings14091096

This article is also based on technical information from Kintek Furnace Knowledge Base .

People Also Ask

- Why is an in-situ XRD system with a high-temperature furnace necessary for Y-W-N ceramics? Capture Real-Time Stability

- What is the purpose of annealing the sapphire substrate at 980 °C with Cr? Achieve Unidirectional Cr2S3 Growth

- What process conditions are provided by the molten NaOH-KOH system? High-Temp Salt Etching for Silicon Recovery

- How does a high-precision temperature control system assist in evaluating the thermal management capabilities of phosphor materials? Pinpoint Performance for Solar Cells.

- How does an autoclave assist in modifying bio-carbon with cobalt oxide? Unlock High-Performance Nano-Composites

- What is an industrial oven and which industries use it? Discover Versatile Thermal Processing Solutions

- How does the control of gas flow and reaction time affect NiMo catalyst carbon layers? Master Nanostructure Engineering

- Why is programmable temperature control in furnaces critical during superalloy aluminization? Ensure High-Yield HTLA