The molten sodium hydroxide-potassium hydroxide (NaOH-KOH) system functions as a high-temperature, high-reactivity chemical medium designed to aggressively strip surface impurities from silicon wafers. By utilizing a molten strong alkali environment, this process provides the specific thermal and chemical energy necessary to decompose robust materials like silicon nitride and silicon dioxide.

The core purpose of this system is to utilize elevated temperatures and strong alkalinity to strip protective layers, resulting in clean silicon wafers and the preliminary separation of metals.

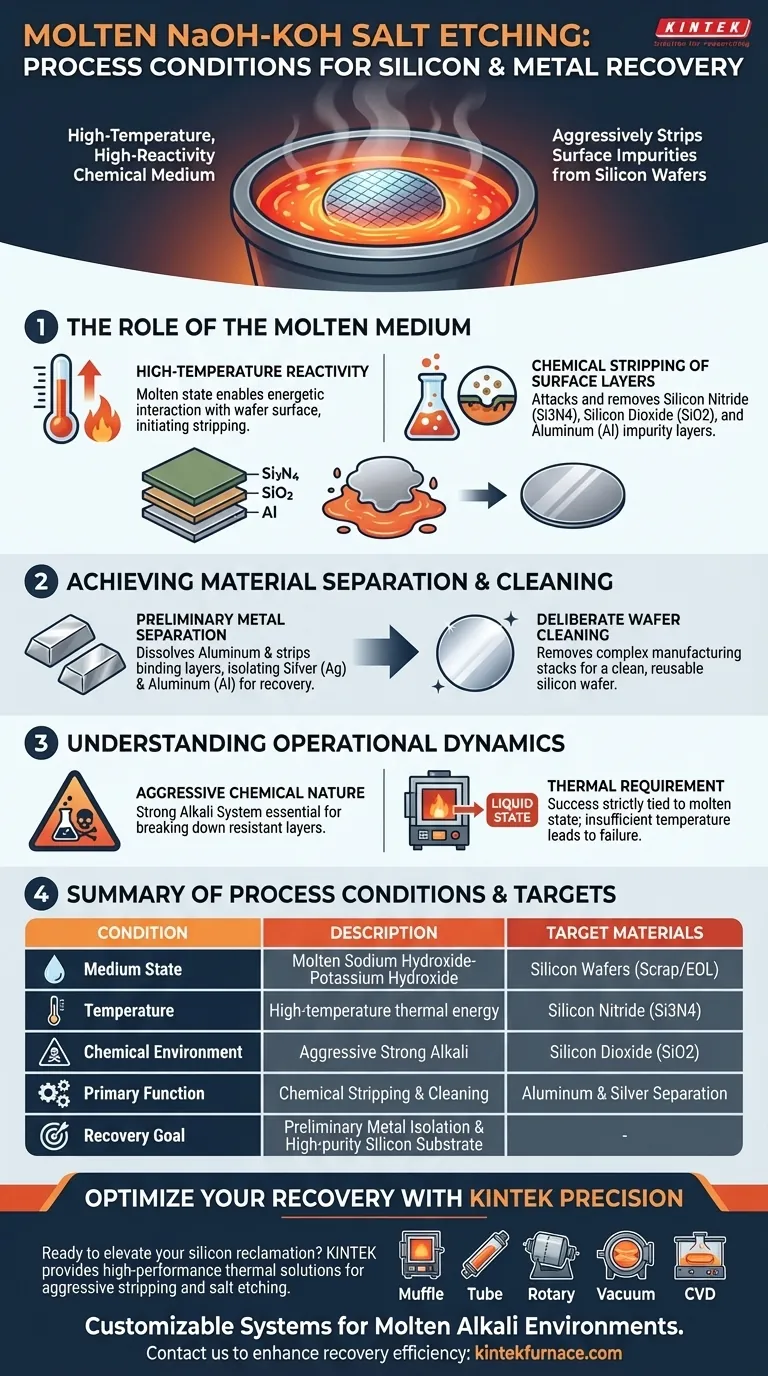

The Role of the Molten Medium

High-Temperature Reactivity

The primary condition provided by this system is an environment of high reactive activity.

The molten state allows the strong alkalis to interact more energetically with the wafer surface than they would in an aqueous solution.

This elevated temperature is not merely a byproduct but a requirement to initiate the chemical stripping process.

Chemical Stripping of Surface Layers

The medium is specifically tuned to attack and remove distinct layers found on solar silicon wafers.

It effectively chemically strips the silicon nitride anti-reflection layer and silicon dioxide.

Additionally, it removes aluminum impurity layers, ensuring the underlying silicon is exposed and cleaned.

Achieving Material Separation

Preparing for Metal Recovery

Beyond cleaning the wafer, the system creates the necessary conditions for resource recovery.

The process facilitates the preliminary separation of silver and aluminum metals.

By dissolving the aluminum and stripping binding layers, the system isolates these metals for subsequent recovery steps.

Deliberate Wafer Cleaning

The ultimate physical outcome of these conditions is a "clean" silicon wafer.

The molten salt environment removes the complex stack of manufacturing coatings that render the wafer unusable for direct recycling.

Understanding the Operational Dynamics

Aggressive Chemical Nature

It is important to recognize that this is a strong alkali system.

The conditions are inherently aggressive to ensure the breakdown of chemically resistant layers like silicon nitride.

The Thermal Requirement

Success in this process is strictly tied to the molten state.

Insufficient temperature would likely result in a loss of reactive activity, failing to strip the impurities or separate the metals effectively.

Making the Right Choice for Your Goal

This process is highly specialized for the recovery of valuable materials from end-of-life or scrap silicon devices.

- If your primary focus is Wafer Reclamation: Ensure the system maintains sufficient temperature to completely strip the silicon nitride and silicon dioxide layers without damaging the wafer substrate.

- If your primary focus is Metal Recovery: Leverage the high-reactivity environment to fully dissolve aluminum impurities, allowing for the efficient isolation of silver.

The molten NaOH-KOH system provides the intense thermal and chemical baseline required to turn complex electronic waste into recoverable raw materials.

Summary Table:

| Process Condition | Description | Target Materials |

|---|---|---|

| Medium State | Molten Sodium Hydroxide-Potassium Hydroxide | Silicon Wafers (Scrap/EOL) |

| Temperature | High-temperature thermal energy | Silicon Nitride (Si3N4) |

| Chemical Environment | Aggressive Strong Alkali | Silicon Dioxide (SiO2) |

| Primary Function | Chemical Stripping & Cleaning | Aluminum & Silver Separation |

| Recovery Goal | Preliminary Metal Isolation | High-purity Silicon Substrate |

Optimize Your Material Recovery with KINTEK Precision

Ready to elevate your silicon reclamation and metal recovery processes? KINTEK provides the high-performance thermal solutions necessary for aggressive chemical stripping and salt etching. Backed by expert R&D and manufacturing, we offer high-temperature Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to withstand the aggressive nature of molten alkali environments.

Don't let valuable materials go to waste. Contact us today to discover how our specialized lab furnaces can enhance your recovery efficiency and deliver cleaner results for your unique research or production needs.

Visual Guide

References

- Yuxuan Sun. Methods and Improvement Measures Based on Solar Panel Recycling. DOI: 10.54254/2755-2721/2025.gl24086

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why must ball milling of aluminum alloy powders be in argon? Ensure Material Integrity & Prevent Oxidation

- What role does a belt-type rapid sintering furnace play in forming metal contacts? Optimize Solar Cell Efficiency

- Why is a specialized roasting simulation device necessary? Optimize Iron Ore Pellet Quality and Strength

- What is the role of a dedicated bias power supply in low-pressure plasma nitriding? Master Ion Acceleration Control

- What is the purpose of preheating metal molds? Enhance Fluidity and Quality in Aluminum-Lithium Squeeze Casting

- Why is pre-calcination of CaO, Al2O3, and V2O5 necessary? Achieve Stoichiometric Accuracy in Slag Samples

- How does the perpendicular orientation of substrate holders benefit VTD? Maximize Efficiency and Thermal Control

- What is the purpose of using a precision oven for HAp-Fe3O4 drying? Achieve 110°C Stability & High Porosity